Blog

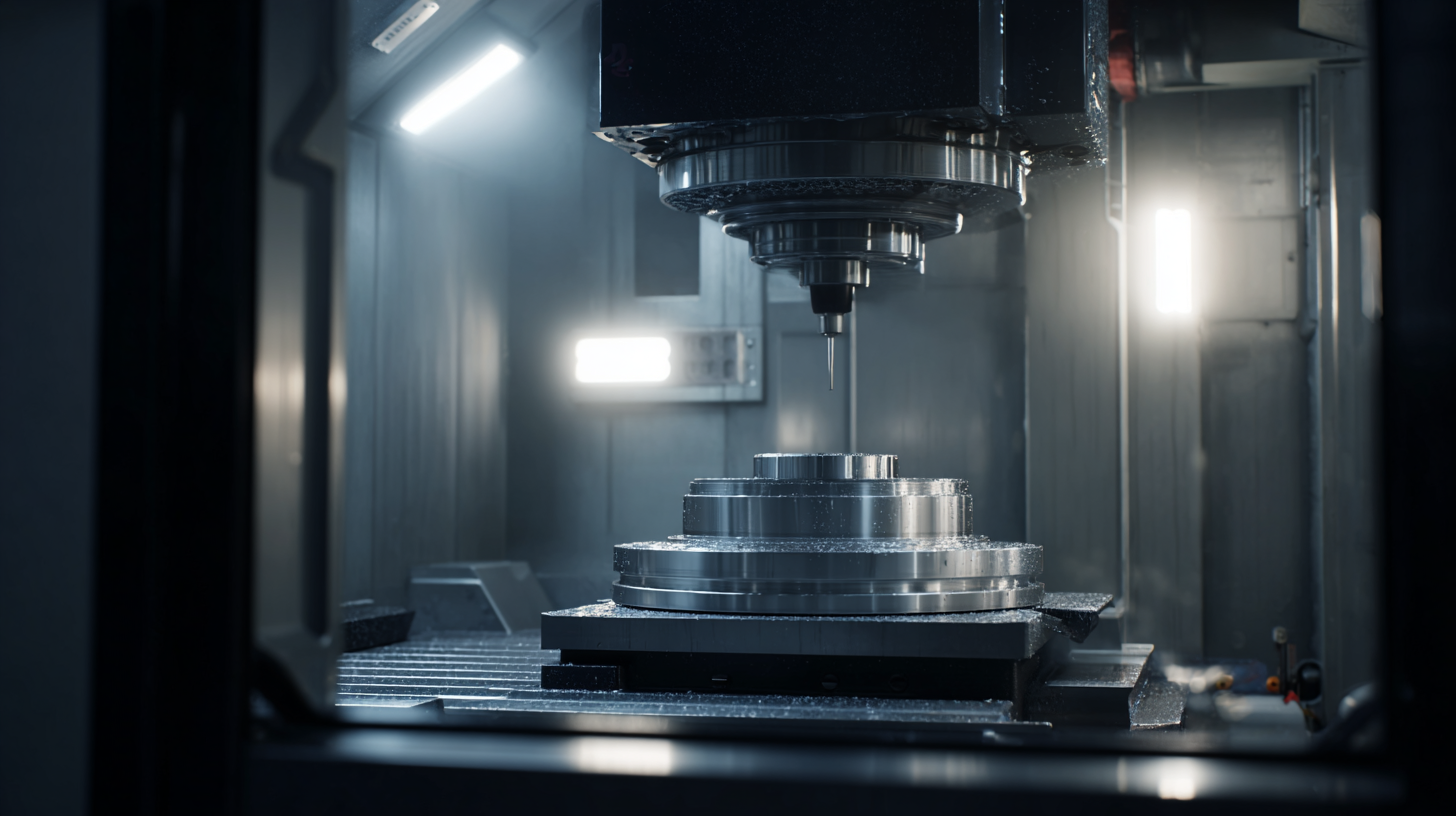

Unlocking the Future of Manufacturing with the Best Horizontal Milling Machine in 2025

As we move into 2025, the manufacturing landscape is poised for transformative advancements, significantly influenced by the adoption of cutting-edge technologies. One of the pivotal tools driving this change is the horizontal milling machine, which is revolutionizing efficiency and precision in manufacturing processes. According to a recent report by MarketsandMarkets, the global milling machine market is expected to reach $5.02 billion by 2025, growing at a CAGR of 6.2%. This surge highlights the crucial role that horizontal milling machines play in increasing productivity and reducing production times. With improved automation and innovative features, these machines not only enhance operational efficiency but also enable manufacturers to produce complex parts with unparalleled accuracy. As industries strive to meet the challenges of a rapidly evolving market, investing in the best horizontal milling machines becomes essential for achieving competitive advantage and unlocking future potential.

The Evolution of Horizontal Milling Machines: Key Features for 2025

The evolution of horizontal milling machines is set to play a pivotal role in the future of manufacturing, particularly as we approach 2025. As the global milling machine market experiences a robust growth trajectory, projected to reach USD 116,722.7 million by 2035, technological advancements in CNC (Computer Numerical Control) systems are driving this transformation. The demand for high-precision and multi-axis machining continues to rise, with the market expected to experience a compound annual growth rate (CAGR) of 5.1% over the coming years. This growth is fueled by the integration of smart automation and the increasing need for efficient manufacturing solutions.

Horizontal milling machines are evolving with key features that enhance speed, accuracy, and versatility. The market for CNC machine tools alone is anticipated to grow by USD 21.9 billion from 2025 to 2029, demonstrating the rising interest in innovative manufacturing technologies. As manufacturers increasingly adopt cutting-edge machines, the focus on design and functionality will likely redefine bar-fed machining applications. By investing in advanced horizontal milling technologies, businesses can leverage these developments to maintain a competitive edge in an increasingly global marketplace.

Top Brands Dominating the Horizontal Milling Machine Market

As we transition into 2025, the horizontal milling machine market is set to experience significant advancements, driven by innovative features and enhanced efficiency. Leading brands are at the forefront of these developments, offering machines that not only meet the needs of modern manufacturing but also promote sustainability. Companies like Haas Automation, DMG MORI, and Makino are revolutionizing the sector with cutting-edge technologies that integrate automation and smart manufacturing practices, ensuring that businesses can keep pace with the dynamic demands of the industry.

Haas Automation continues to deliver robust and reliable machines equipped with user-friendly controls and powerful capabilities. Their commitment to quality and performance makes them a favorite among manufacturers. Meanwhile, DMG MORI blends precision engineering with revolutionary software solutions, allowing for seamless integration into existing workflows. Makino, on the other hand, emphasizes efficiency and speed, making their horizontal milling machines ideal for high-volume production. These top brands are not only driving the evolution of horizontal milling machines but are also empowering manufacturers to unlock unprecedented potential in their operations, shaping the future of the industry.

How Digital Technology is Transforming Horizontal Milling Processes

The advent of digital technology is fundamentally reshaping the landscape of horizontal milling processes, paving the way for enhanced efficiency and precision in manufacturing. According to a report by MarketsandMarkets, the global digital manufacturing market is projected to grow from $158 billion in 2020 to over $505 billion by 2025, highlighting the rapid integration of technology in manufacturing operations.

Horizontal milling machines equipped with advanced CNC (Computer Numerical Control) systems are at the forefront of this transformation, allowing for greater automation, reduced lead times, and improved product consistency.

In-line with this digital evolution, Industry 4.0 principles are increasingly being adopted in horizontal milling operations. Embracing IoT (Internet of Things) connectivity, manufacturers can now gather real-time data from milling machines, enabling predictive maintenance and minimizing downtime. A recent study from Deloitte indicates that companies implementing IoT in their manufacturing processes can achieve up to a 30% increase in productivity. As we look towards 2025, the integration of AI-driven algorithms in horizontal milling machines is expected to further optimize machining parameters, ensuring that the future of manufacturing remains agile and responsive to market demands.

5 Reasons to Invest in a Horizontal Milling Machine for Future-Proofing

As we look towards 2025, the manufacturing landscape is rapidly evolving, and investing in a horizontal milling machine is a strategic move that can future-proof businesses. One compelling reason is automation. According to a report from McKinsey, automation can enhance productivity by up to 30% in manufacturing operations, and horizontal milling machines are at the forefront of this transformation. Their ability to perform multiple operations in one setup reduces downtime and streamlines processes, making them ideal for high-volume production.

Moreover, industry research from MarketsandMarkets indicates that the global CNC machining market is projected to reach USD 100 billion by 2025, driven by innovations in horizontal milling technology. These machines deliver superior precision and can accommodate a variety of materials, ensuring manufacturers can meet diverse customer demands. Investing in a state-of-the-art horizontal milling machine positions companies to capitalize on this growth and maintain a competitive edge by minimizing waste and maximizing efficiency.

Finally, the versatility of horizontal milling machines allows for greater customization in production, enabling manufacturers to rapidly respond to market trends. A shift towards sustainable practices and the need for more complex designs make these machines invaluable for businesses aiming to stay relevant in an increasingly dynamic environment.

Sustainability in Manufacturing: The Role of Horizontal Milling Machines in 2025

In the rapidly evolving landscape of manufacturing, sustainability has emerged as a key driving force. Horizontal milling machines, renowned for their precision and efficiency, will play a pivotal role in reshaping the industry's approach to environmental stewardship by 2025. These machines, capable of processing large workpieces with minimal waste, are positioned to significantly reduce material consumption and energy usage. Their ability to recycle and repurpose scrap has paved the way for a more sustainable manufacturing process, aligning with growing consumer demand for eco-friendly products.

Moreover, advancements in technology will enhance the capabilities of horizontal milling machines, integrating smart manufacturing principles. By implementing IoT (Internet of Things) and AI (Artificial Intelligence), manufacturers can monitor machine performance in real-time, optimize energy consumption, and minimize downtime. This level of efficiency not only contributes to sustainability efforts but also boosts overall productivity. As companies invest in the best horizontal milling machines, they are not just upgrading their equipment; they are committing to a greener future in manufacturing that prioritizes both the planet and profitability.