Blog

Unlock Precision: How a Small CNC Mill Transforms Your DIY Projects into Professional Creations

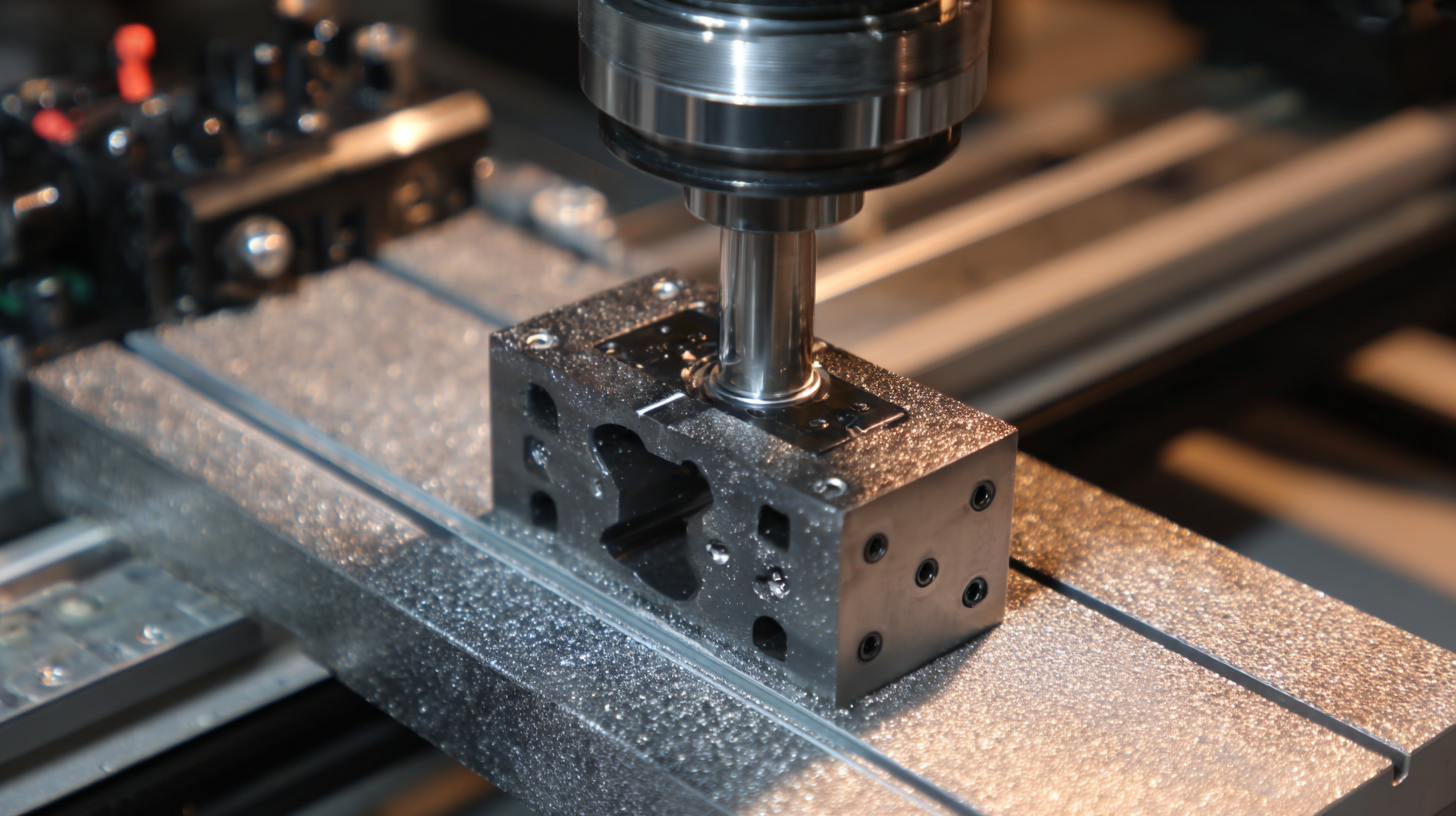

In the world of DIY projects, precision and craftsmanship can make all the difference between an amateur creation and a professional masterpiece. Enter the small CNC mill, a revolutionary tool that empowers hobbyists and creators to unlock their full potential. With its ability to perform intricate cuts and designs with unparalleled accuracy, a small CNC mill transforms ordinary materials into stunning works of art. Whether you're crafting custom furniture, prototyping unique gadgets, or producing intricate models, this compact machinery elevates your work to the next level.

As we explore the myriad benefits of utilizing a small CNC mill, we'll uncover how it empowers enthusiasts to achieve precision like never before, ultimately turning their visionary ideas into tangible realities. Discover how integrating this technological marvel into your projects can unleash a new wave of creativity and professionalism in your DIY journey.

Choosing the Right Small CNC Mill for Your DIY Projects

When embarking on DIY projects, selecting the right small CNC mill is crucial for achieving professional-quality results. The first step is to evaluate your specific needs and the materials you plan to work with. Small CNC mills are typically designed for various applications, from woodworking to metalworking, so understanding your project requirements will help narrow down your options. Consider the mill's compatibility with different materials, its cutting capabilities, and the level of precision it offers.

Another important factor to consider is the size and footprint of the CNC mill. If you have limited workspace, opt for a compact model that still delivers accuracy and power. Additionally, look into features such as ease of use, software compatibility, and customer support. A user-friendly interface can significantly reduce your learning curve and enhance your efficiency. By choosing the right small CNC mill tailored to your DIY projects, you can unlock new creative possibilities and elevate your craftsmanship to a professional level.

Essential Features to Look for in a Small CNC Mill

When considering the integration of a small CNC mill into your DIY projects, understanding the essential features can significantly elevate your creations. One of the most critical aspects is the machine's precision. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.38 billion by 2025, underscoring the increasing demand for precise manufacturing tools. A small CNC mill offers a resolution typically around 0.001 inches, which is vital for projects requiring intricate details and tight tolerances.

Another essential feature to look for is the software compatibility. Most modern small CNC mills come equipped with user-friendly software that supports various file types, enabling seamless operation for both hobbyists and professionals. In fact, a survey by IBISWorld indicates that over 70% of small to mid-sized firms using CNC technology reported a heightened efficiency in their production processes. Furthermore, consider the spindle speed and power; higher RPMs allow for better material removal rates, enhancing project turnaround times. Selecting a small CNC mill with these key features will undoubtedly transform your DIY projects from mundane to magnificent, providing that professional finish you aspire to achieve.

Unlock Precision: Essential Features of Small CNC Mills

Step-by-Step Guide: Setting Up Your CNC Mill for Precision Work

Setting up your small CNC mill is the crucial first step to achieving precision in your DIY projects. Begin by ensuring that your workspace is organized and that you have the necessary tools at hand. Carefully read the manufacturer’s instructions to understand the specific requirements for your machine. This includes assembling any components, calibrating the mill, and ensuring that it is level on a sturdy surface. The initial setup will greatly influence the accuracy of your future projects.

Next, focus on the software aspect of your CNC mill. Install the recommended software required for design and operation, and familiarize yourself with its interface. Import or create a design file using a CAD program, and generate the corresponding G-code, which instructs the CNC mill on how to execute the design. Take the time to run test cuts on scrap material to fine-tune your settings, such as feed rate and spindle speed. This hands-on approach allows for adjustments that will lead to more professional finishes in your final creations.

Unlock Precision: How a Small CNC Mill Transforms Your DIY Projects into Professional Creations

| Feature | Description | Benefits |

|---|---|---|

| Precision Cutting | CNC mills offer high accuracy in cutting and shaping materials. | Improves the quality and consistency of DIY projects. |

| Versatile Materials | Can work with wood, metal, plastic, and more. | Allows for a wide range of projects and applications. |

| User-Friendly Software | Most CNC mills come with easy-to-learn design software. | Simplifies the design process for beginners. |

| Compact Size | Small footprint suitable for home and workshop use. | Easy to integrate into any DIY space. |

| Cost-Effective | Affordable options available for hobbyists and small businesses. | Maximizes value for DIY enthusiasts. |

Techniques to Enhance the Quality of Your CNC Machined Creations

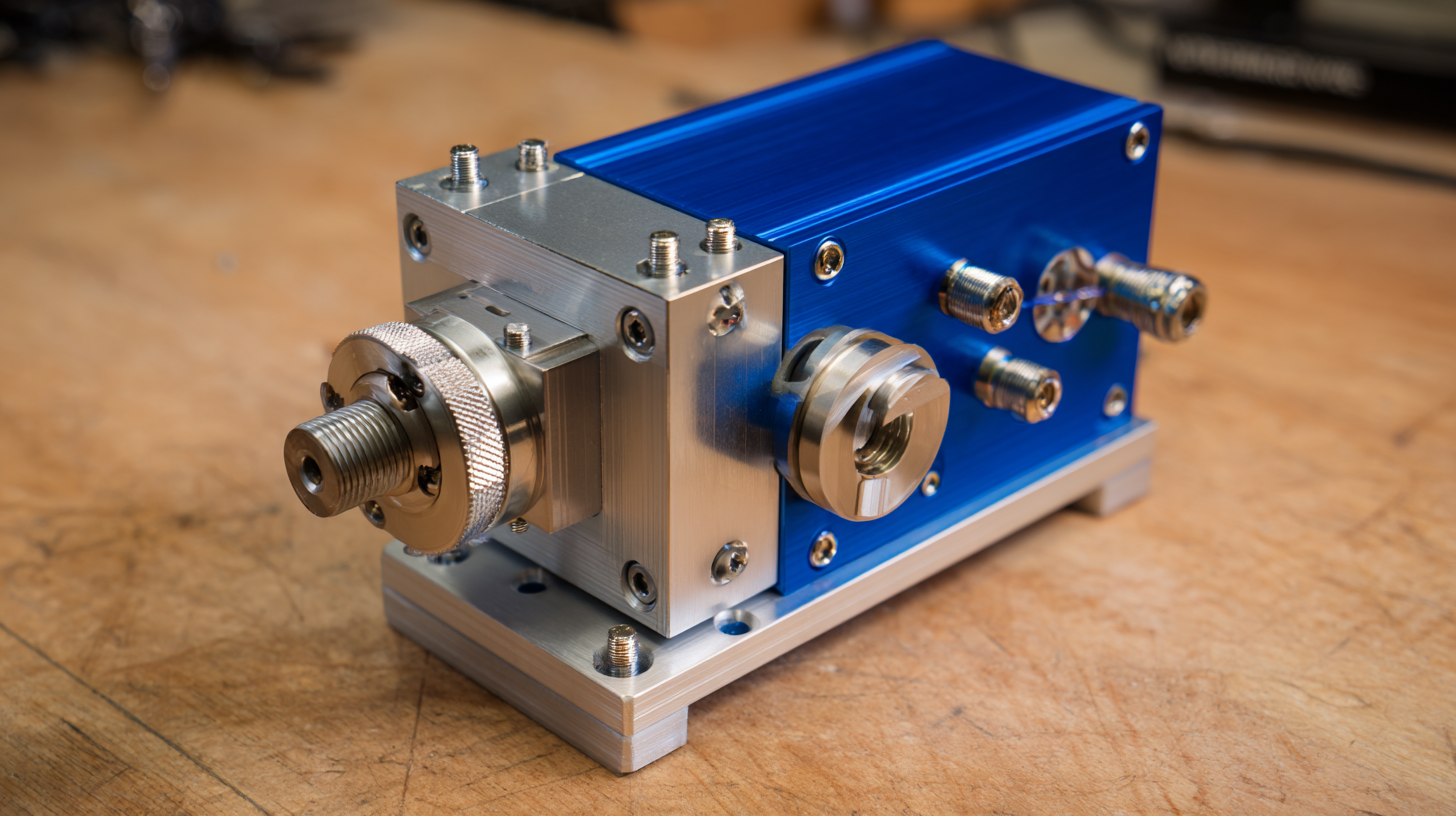

When it comes to enhancing the quality of CNC machined creations, the techniques you employ can significantly impact the outcome. According to a recent report from the International Journal of Advanced Manufacturing Technology, incorporating a high-precision CNC mill can improve accuracy by up to 90%, allowing DIY enthusiasts to achieve professional-grade results in their projects. By mastering feed rates, spindle speeds, and tool selection, you can elevate the finish quality of your machined parts.

Tips: Always start with a proper setup; alignment is key to precision. Use high-quality cutting tools suited for the material you’re working with to ensure clean cuts and minimize wear. Moreover, consider utilizing a mist or flood coolant to reduce heat build-up during machining, which can affect the integrity of your creations.

Moreover, implementing advanced CAM (Computer-Aided Manufacturing) software can further enhance your projects' quality. It allows for precise path optimization and error reduction, streamlining the machining process. According to the latest data from the Manufacturing Institute, companies using advanced machining technologies report a 30% increase in efficiency. Combining these techniques with diligent planning and consistency will undoubtedly yield impressive results in your DIY ventures.

Common Mistakes to Avoid When Using a CNC Mill for DIY Projects

When venturing into the world of CNC milling for DIY projects, it's crucial to understand common mistakes that can hinder the quality of your creations. One prevalent mistake is improper tool assembly and maintenance, particularly when using ER collets. According to industry reports, misaligned tools can lead to inaccuracies in cutting, resulting in wasted materials and time. Ensuring that your collet is clean and properly tightened can help achieve consistent performance.

Another mistake is underestimating the material compatibility with your CNC mill’s capabilities. Projects like the Bridge Boy use inexpensive DC rotary mills that can effectively cut softer materials like plastic and wood. However, pushing these machines beyond their limits can cause tool wear and reduce precision. It's essential to be aware of the specifications of your tools and materials to preserve accuracy.

Tips:

- Always double-check your tool assembly before starting a project to avoid misalignment.

- Use the appropriate feed rates and speeds tailored to the material being machined, as this can significantly impact the finish quality.

- Regular maintenance of your machinery can prevent most common issues, ensuring a longer lifespan and higher quality outputs in your DIY creations.

Related Posts

-

Understanding the Importance of Best CNC Manufacturing in Global Supply Chains

-

Unmatched Quality: Discover the Best Small CNC Mill from Trusted Chinese Manufacturers

-

Choosing the Top 7 Features of the Best CNC Milling Machine Manufacturers

-

Mastering Precision Crafting with the Best CNC Lathe Machine Comprehensive Tutorial for Beginners

-

Master Your Craft with the Ultimate Guide to the Best Small CNC Machine for Your Business

-

Ultimate Guide to Choosing the Best 5 Axis CNC Milling Machine for Your Manufacturing Needs