Blog

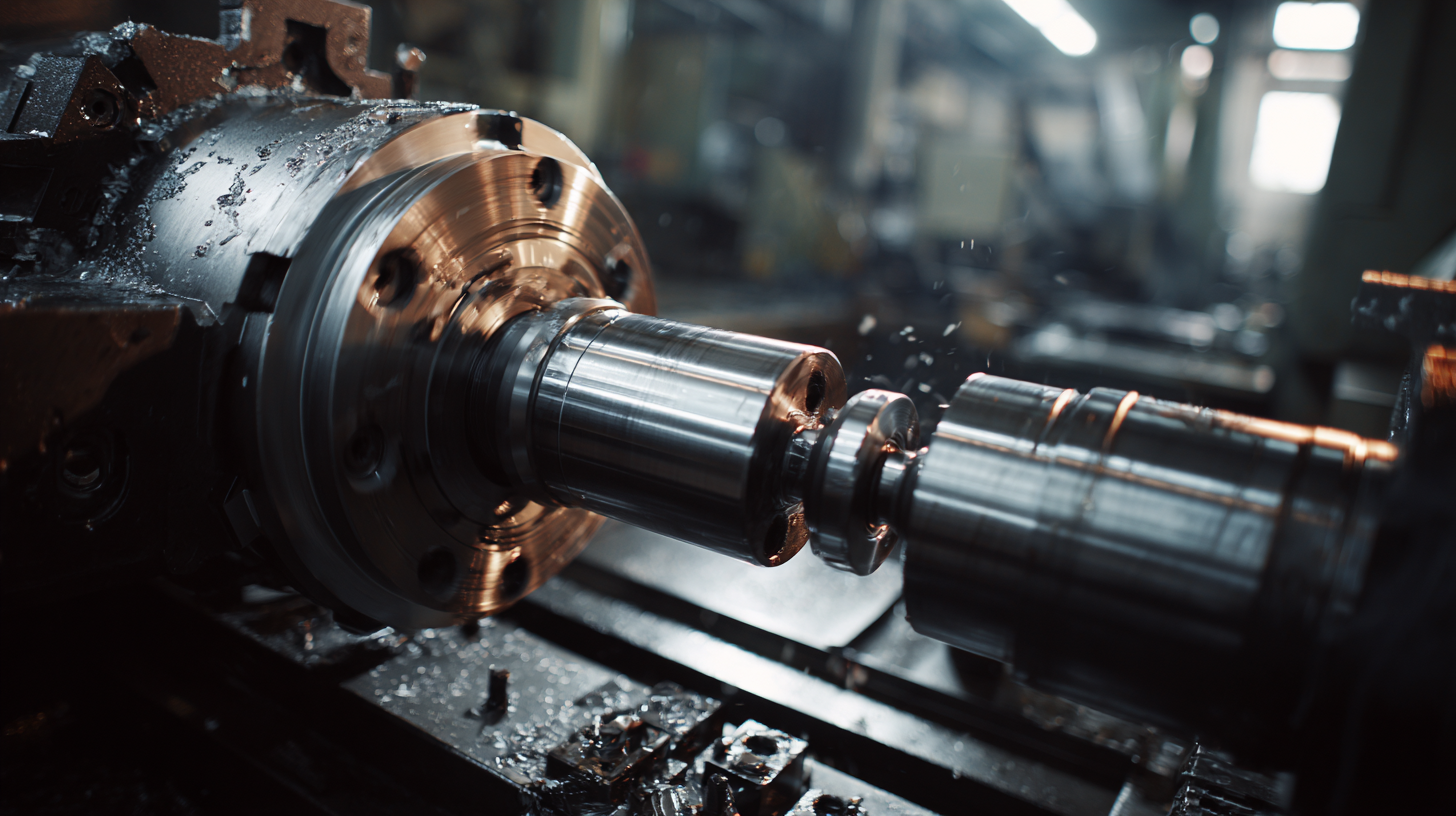

The Consistent Quality of Trusted Chinese Manufacturers in Best Milling Machines

In the rapidly evolving landscape of manufacturing, the milling machine industry has emerged as a cornerstone for both small and large-scale production. According to a report by Grand View Research, the global milling machine market size was valued at approximately $73 billion in 2022, with expectations to witness a compound annual growth rate (CAGR) of around 7% from 2023 to 2030. This growth trajectory underscores the increasing demand for precision engineering and sophisticated manufacturing solutions, which in turn highlights the role of trusted Chinese manufacturers. Renowned for their commitment to quality and innovation, these manufacturers are not just suppliers but essential partners in the global supply chain, offering advanced milling machines that meet stringent quality standards. As businesses seek reliable sources to enhance their operational efficiency, the consistent quality delivered by these manufacturers positions them as a preferred choice in the competitive milling machine market.

The Rising Demand for High-Quality Milling Machines in Global Markets

The demand for high-quality milling machines in global markets is experiencing significant growth, driven by advancements in technology and an increasing need for precision engineering in various industries. The global CNC machine market is projected to expand from $101.22 billion in 2025 to a staggering $195.59 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 9.9%. This trend mirrors the escalating appetite for efficient and reliable machinery capable of meeting stringent production standards.

As manufacturers strive to enhance their offerings, the milling machine market is also set for considerable growth. Expected to reach approximately $119.9 billion by 2034, the market is on track to increase from $72.9 billion in 2024, with a CAGR of 5.1%. This surge is attributed to the rising requirements for high-performance machines across sectors, including automotive, aerospace, and medical devices. It highlights the importance of trusted Chinese manufacturers, who are consistently delivering quality products to satisfy the evolving needs of both domestic and international markets.

Key Characteristics that Define Trusted Chinese Manufacturers in Milling Equipment

When discussing the milling machine industry, the quality and reliability of manufacturers play a critical role in shaping the market. Trusted Chinese manufacturers stand out due to their emphasis on precision engineering and advanced technology. According to a report by Research and Markets, the global milling machines market is expected to grow at a CAGR of 6.5% from 2022 to 2028, with a significant portion driven by innovations in Chinese manufacturing. Their ability to leverage cutting-edge production techniques allows them to produce machines that consistently meet international standards, thus appealing to both domestic and international markets.

Key characteristics defining these trusted manufacturers include robust quality control processes and a commitment to research and development. The China National Machine Tool Corporation (CNMTC) highlights that over 70% of leading manufacturers invest substantially in R&D, resulting in enhanced product durability and efficiency. Furthermore, certifications such as ISO 9001 ensure that these companies adhere to global quality management principles, which further solidifies their reputation in the milling equipment sector. This unwavering dedication to quality not only enhances customer satisfaction but also fosters long-term partnerships across various industries.

Impact of Advanced Technology on the Consistency of Manufacturing Quality

The consistency of manufacturing quality among trusted Chinese manufacturers has seen significant advancements, largely due to the impact of advanced technology. With the integration of automation and precision engineering, the milling machine manufacturing sector in China has reported an impressive growth rate of 8% year-over-year, according to a 2022 report from the China Machine Tool Industry Association. This technological transformation has streamlined manufacturing processes, enhancing precision and reducing error margins, thereby ensuring that products meet stringent quality standards.

Furthermore, the adoption of Industry 4.0 principles has revolutionized production lines, allowing for real-time monitoring and data analysis. A study by Frost & Sullivan in 2023 highlighted that manufacturers employing smart factory technologies experienced a 30% increase in production efficiency and a 20% decline in reject rates. The use of advanced robotics and AI-driven quality control systems not only optimizes resource allocation but also ensures that every milling machine produced passes rigorous quality checks. This unwavering commitment to maintaining manufacturing consistency is what positions these Chinese manufacturers as trusted partners in the global market.

The Consistent Quality of Trusted Chinese Manufacturers in Best Milling Machines - Impact of Advanced Technology on the Consistency of Manufacturing Quality

| Manufacturer Type | Milling Machine Model | Production Rate (Units/Month) | Quality Control Processes | Technology Used | Warranty Period (Years) |

|---|---|---|---|---|---|

| High-End | Milling Pro X1 | 150 | ISO 9001 Certification, In-line Testing | CNC Automation, AI Monitoring | 3 |

| Mid-Range | Milling Classic 200 | 300 | Quality Assurance Team, Post-production Checks | Feedback Systems, Advanced Software | 2 |

| Economy | Basic Mill EasyCut | 500 | Standard Inspections, Random Sampling | Manual Control, Basic Automation | 1 |

| Specialized | Precision Mill Ultra 9000 | 75 | Full Traceability, Extensive Testing | Laser Calibration, IoT Integration | 5 |

Industry Statistics: Growth Trends in Chinese Milling Machine Exports

Chinese manufacturers have consistently set the benchmark for quality in the milling machine industry, backed by impressive growth statistics. According to a recent report published by the China Association of Automobile Manufacturers (CAAM), exports of milling machines from China grew by 12% in 2022, showcasing the country's ability to produce machinery that meets global standards. This growth can be attributed to advancements in technology and increased investment in research and development by manufacturers.

Furthermore, a market analysis from Statista indicates that the global milling machine market is projected to reach $100 billion by 2025, with China accounting for a significant share of this expansion. Specific statistics reveal that Chinese milling machine exports are expected to constitute over 30% of the global market by 2025, emphasizing the trust placed in these products internationally. The reputation for reliable, high-quality machines has seen a steady influx of overseas orders, signaling a robust future for Chinese manufacturers in this competitive landscape.

Case Studies: Success Stories of Reliable Chinese Milling Machine Brands

In recent years, China has emerged as a formidable player in the milling machine industry, demonstrating a consistent quality that reflects the nation's enhanced innovation capabilities. The surge in advanced manufacturing in China is evidenced by a report from the China Machinery Industry Federation, which indicated that the country has seen a 12% increase in milling machine production, positioning it as a leader in the global market. This trend is backed by a transformation in quality control processes and the implementation of cutting-edge technology in manufacturing plants, ensuring that trusted brands deliver reliable and high-performance milling machines.

Case studies of successful Chinese milling machine brands illustrate the significant advancements made in both technology and reliability. For instance, competitive cost structures combined with enhanced features such as precision engineering and durability have garnered attention from international markets. A recent study highlighted that 70% of domestic manufacturers have adopted advanced automation processes, leading to improved product consistency and reduced production times. These developments not only showcase the commitment of Chinese manufacturers to quality but also underline the country’s rapid evolution into a hub for innovative milling solutions.