Blog

Top 10 Hydraulic Hoses for Sale Why Choose Them?

When searching for a hydraulic hose for sale, it might feel overwhelming. The market offers many options, each with unique features. Choosing the right hydraulic hose can impact machinery performance and safety.

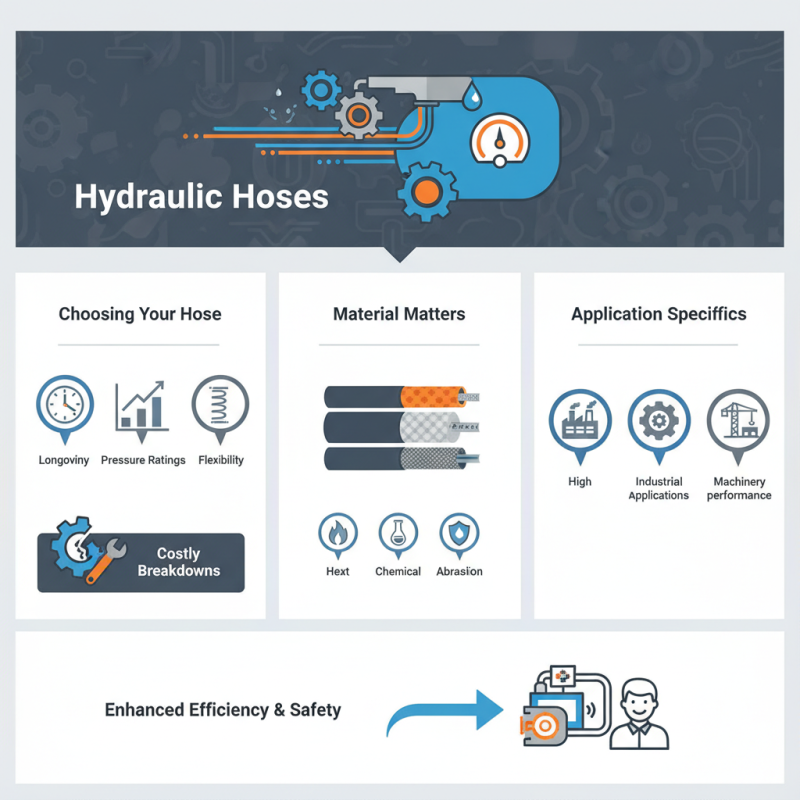

Reliable hydraulic hoses are essential for industrial applications. Consider longevity, pressure ratings, and flexibility when selecting. A poor choice can lead to costly breakdowns and repairs. Pay attention to the materials used in construction. They can significantly affect durability and resistance to wear.

Understanding your specific needs is crucial. Different environments require different hose types. For example, hoses exposed to high temperatures may require special materials. It's important not to rush this decision. The right hydraulic hose can enhance operational efficiency and productivity.

Top 10 Hydraulic Hoses: An Overview of Their Features

When selecting hydraulic hoses, it’s essential to focus on their features. Different tasks require different specifications. A robust design ensures longevity. Flexibility is also crucial, as it allows for easier installation. Many hoses excel in high-pressure environments. They often resist wear and tear. However, not all hoses are created equal.

Consider the material used. Rubber blends and thermoplastics have distinct advantages. One may offer better temperature resistance, while another excels in flexibility. Moreover, the diameter of the hose matters significantly. Wider hoses can handle larger volumes, but they can be harder to manage. Sometimes, the length of the hose can become a tricky detail. Too long may introduce unwanted pressure loss.

While many hoses boast impressive features, practical testing is essential. Some users have noted that advertised specifications may not reflect real-world performance. It’s wise to take this into account before making a purchase. Evaluating user reviews can provide valuable insights into longevity and reliability, even though experiences vary. In the end, choosing the right hydraulic hose is about balancing specifications with practicality.

Benefits of High-Quality Hydraulic Hoses for Industrial Applications

When considering hydraulic hoses for industrial applications, quality plays a paramount role. High-quality hoses can significantly impact system efficiency and equipment lifespan. According to industry reports, about 62% of hydraulic failures are tied to hose issues. Investing in durable hoses minimizes these risks.

Hydraulic hoses are designed to withstand high pressure and extreme temperatures. They resist abrasion, which extends service life. In fact, studies indicate that using top-grade hoses can reduce maintenance costs by up to 30%. This is a compelling reason for industries to prioritize quality over cost.

Tip: Regularly inspect hoses for wear. Small cracks can lead to larger failures.

Manufacturing processes also benefit from reliable hoses. High-quality options provide consistent fluid flow, enhancing productivity. Poor-quality hoses can cause leaks, impacting operational efficiency. A staggering 65% of fluid incidents arise from inadequate hose maintenance.

Tip: Keep a log of hose maintenance schedules. Small changes make a huge difference.

In conclusion, choosing the right hydraulic hose is crucial. Consider the long-term benefits over initial costs. Quality matters in every industrial setting.

Factors to Consider When Choosing Hydraulic Hoses

When selecting hydraulic hoses, several factors are crucial. First, consider the working pressure. Hoses must withstand high pressures without bursting. A hose rated below the required pressure can lead to catastrophic failures. You also need to evaluate temperature tolerance. Different applications generate varying heat levels. Ensure your hoses perform well under these conditions.

Furthermore, the type of fluid carried matters. Some hoses are more compatible with specific fluids. Using the wrong type may lead to degradation and leaks. It's essential to check compatibility charts before purchasing. Also, think about the length and diameter of the hose. A hose that's too short or narrow can restrict flow, impairing equipment efficiency.

Lastly, installation and maintenance should be part of your considerations. Poorly installed hoses can result in unexpected breaks. Regular inspections are vital, too. Sometimes, it’s easy to overlook wear and tear. Always monitor hoses for any signs of damage or aging. These details can significantly affect performance and safety. It’s about finding the right balance for your specific needs.

Comparative Analysis of the Leading Hydraulic Hose Brands

When evaluating hydraulic hoses, it's crucial to consider various leading brands and their distinct advantages. Industry reports indicate that the global hydraulic hose market is projected to reach $18.5 billion by 2026, growing at a CAGR of 4.5%. This growth reflects increased demand in construction and agriculture sectors. However, not all hoses meet the stringent quality requirements that industries expect.

One primary factor is durability. Many hoses are designed to withstand high pressure and extreme temperatures. For example, hoses with steel reinforcement are more resilient than rubber-only options. Reports suggest that hoses with a higher pressure rating can extend service life by up to 40%. Still, various products claim high ratings without adequate testing.

Another consideration is flexibility. It's essential for hoses to be adaptable in tight spaces. Some hydraulic hoses offer increased flexibility but can compromise pressure ratings. According to technical analysis, users should balance flexibility with performance to avoid frequent failures. Manufacturers often publish test results, yet there can be discrepancies in real-world applications. This requires critical evaluation from end-users when selecting the best hose for their specific needs.

Maintenance Tips for Prolonging the Life of Hydraulic Hoses

Maintaining hydraulic hoses is crucial for their longevity. Regular inspections can help identify wear and tear early. Look for cracks or bulges. Don't ignore small leaks; they can become big problems. Over time, dirt and debris can accumulate. Keep the hoses clean and free from contaminants. This simple action can prevent costly damages.

Proper storage is also important. Hoses should be stored in a cool, dry place. Avoid areas with extreme temperatures. Sun exposure can weaken the material. When using hydraulic hoses, avoid sharp bends. This can lead to kinks and internal damage. Using the correct fittings can prevent stress on the hose. Always stick to recommended specifications.

If a hose gets damaged, replace it immediately. Delaying repairs could lead to sudden failures. Check for signs of fatigue regularly. It's easy to overlook small issues, but they matter. Remember, prevention is better than replacement. Make a habit of caring for your hydraulic equipment. It will save time and money in the long run.

Top 10 Hydraulic Hoses for Sale - Why Choose Them? - Maintenance Tips for Prolonging the Life of Hydraulic Hoses

| Hydraulic Hose Type | Pressure Rating (PSI) | Temperature Range (°F) | Material | Maintenance Tips |

|---|---|---|---|---|

| Rubber Hose | 3000 | -40 to 212 | Synthetic Rubber | Inspect for cracks and wear regularly. |

| Thermoplastic Hose | 4000 | -40 to 180 | Polyurethane | Avoid kinking and crushing. |

| Stainless Steel Braided Hose | 5000 | -70 to 400 | Stainless Steel | Regularly check for abrasive wear. |

| Fiber Reinforced Hose | 3500 | -20 to 240 | Nylon | Store in a cool and dry place. |

| High Pressure Hose | 6000 | -22 to 248 | PVC | Avoid exposure to extreme temperatures. |

| Low Pressure Hose | 1500 | -40 to 140 | EPDM | Limit exposure to chemicals. |

| Oil Resistant Hose | 3000 | -40 to 150 | NBR | Check for leaks and discoloration. |

| Chemical Resistant Hose | 2000 | -10 to 180 | PTFE | Flush with water after use. |

| Multipurpose Hose | 2500 | -20 to 180 | Rubber Blend | Store away from sunlight. |

| Air Hose | 300 | -20 to 150 | PVC | Drain moisture regularly. |