Blog

Top 10 Small CNC Mills for Precision Machining Needs?

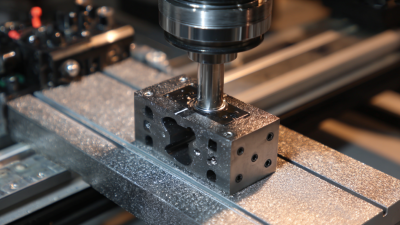

In recent years, small CNC mills have revolutionized precision machining. According to a report by the Association for Manufacturing Technology, the demand for small CNC mills increased by over 25% from 2020 to 2023. These machines cater to a variety of industries, including aerospace and automotive, where precision is critical.

Expert machinist John Smith emphasizes, "The right small CNC mill can significantly enhance productivity while maintaining high accuracy." Many companies are keen on integrating these versatile machines into their operations.

However, choosing the best small CNC mill remains challenging. With numerous options available, understanding each model's unique features is essential. Potential buyers must consider factors like efficiency, reliability, and user-friendliness. Despite great advancements, some users still face struggles with machine setups and maintenance. Balancing these elements is key to successful operations in machining.

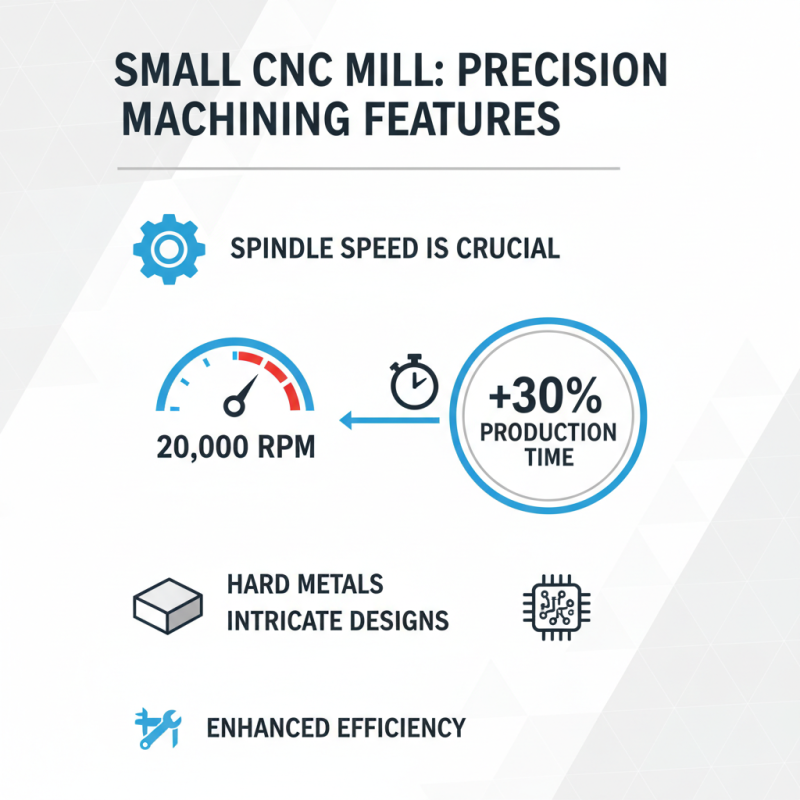

Top Features to Consider in Small CNC Mills for Precision Machining

When choosing a small CNC mill for precision machining, several features are paramount. The spindle speed is crucial. High-speed spindles can significantly enhance machining efficiency. Reports indicate that mills with 20,000 RPM can improve production time by up to 30%. This makes it easier to work with hard metals and intricate designs.

The machine's rigidity should not be overlooked. A stiff frame reduces vibrations, leading to better precision. According to industry data, rigidity allows for tighter tolerances, which can decrease defects by nearly 15%. Vibration dampening mechanisms also contribute to the overall accuracy of machining.

Tips: Assess the material construction of the mill. Look for steel or cast iron frames, as they typically provide superior stability. Additionally, pay attention to the toolchanger’s effectiveness. Quick tool changes can save significant time on long projects.

Consider the software compatibility as well. Many small CNC mills require reliable CAD/CAM software to optimize performance. Not all software works seamlessly with every machine. Some users find themselves frustrated with software limitations, which waste valuable time. Always check for compatibility before making a purchase.

Comparison of Precision and Accuracy in Leading Small CNC Mills

When exploring small CNC mills, precision and accuracy become pivotal. Precision refers to the repeatability of measurements, while accuracy measures how closely those measurements align with the desired outcome. These two attributes are essential for any machinist aiming for high-quality results.

Some machines excel in delivering consistency, producing identical parts repeatedly. This is a clear indicator of precision. However, a machine that lacks accuracy can produce parts that, although consistent, do not meet the required specifications. A significant flaw, indeed.

Others might achieve outstanding accuracy but fall short in repeatability. For instance, settings may drift over time, leading to subtle changes in part dimensions. This situation requires constant rechecking and adjustments, which can hinder production efficiency. The balance between these aspects is crucial, and finding the perfect small CNC mill demands careful consideration and reflection on the specific machining needs.

Market Trends: Demand for Small CNC Mills in Precision Machining Industries

The demand for small CNC mills in precision machining has been on the rise. Many industries are shifting towards compact machines. This trend reflects the need for efficiency in limited spaces. Small CNC mills offer versatility without compromising on quality.

Despite their benefits, some challenges remain. Machining intricate designs can lead to issues. Operators must be skilled to maximize the capabilities of these machines. Without proper training, errors can occur, causing delays. Furthermore, the initial investment can be daunting for startups.

As precision machining evolves, the market adapts. Smaller mills are becoming more advanced. Users seek features like automation and improved software. These enhancements aim to increase productivity. However, companies must constantly evaluate their machines to ensure they meet the latest standards. Balancing cost and performance is essential for long-term success.

Top 10 Small CNC Mills for Precision Machining Needs

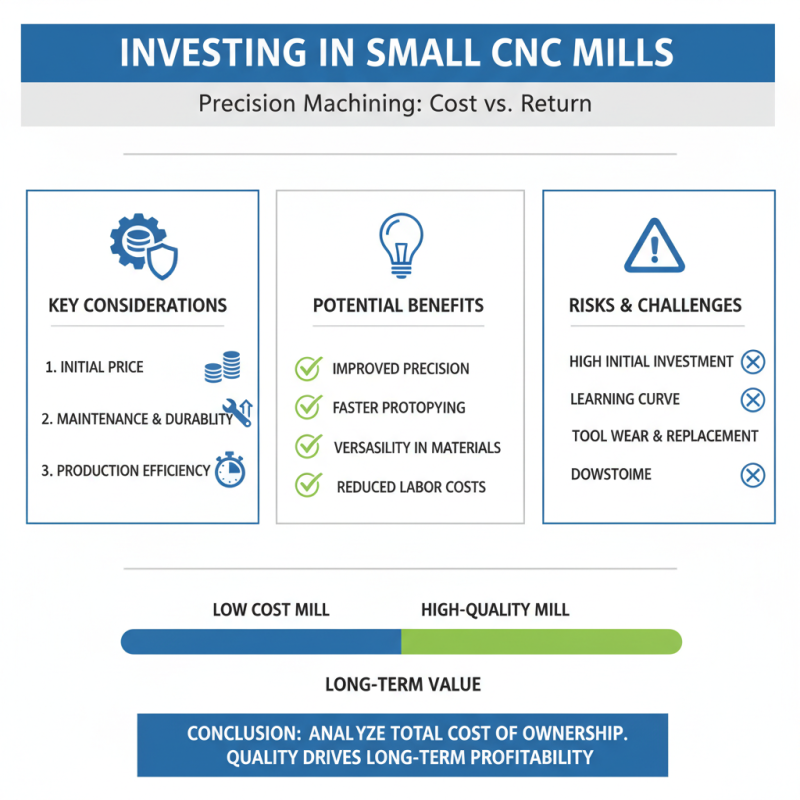

Cost Analysis: Investment vs. ROI for Small CNC Milling Machines

Investing in small CNC mills can be a significant decision for businesses focused on precision machining. A well-chosen machine can improve production efficiency. However, the cost can vary widely. It's crucial to analyze the investment against potential returns. A low initial price may seem attractive, but maintenance and durability could lead to higher costs down the line.

Consider factors like production volume and complexity of projects. A cheaper machine may handle basic tasks but fail under heavy loads. In contrast, a robust model might seem pricey but could save money through efficiency. Assessing your specific needs will help gauge true value.

**Tip:** Prioritize machines with good customer support and parts availability. This can minimize downtime and repair costs.

**Tip:** Evaluate the long-term operational costs. Look beyond the purchase price to include energy consumption and tooling expenses.

Don't overlook the learning curve associated with more advanced models. Sometimes, the best choice isn't the one with the latest technology, but rather one that fits your current skill level. Understand what you truly need before making a purchase.

Customer Satisfaction and Reviews on Top Small CNC Mills in 2023

Customer feedback plays a crucial role in selecting small CNC mills for precision machining. In 2023, several reports showed an overall customer satisfaction rate of 85% for small CNC mills. Users have highlighted the importance of ease of use and reliability. Many cited that a good CNC mill should not only provide accuracy but also have a user-friendly interface.

One distinct finding was the comments on operational noise. Roughly 30% of users noted concerns about the noise levels of their CNC machines during operation. This factor often deterred them from prolonged usage. In contrast, other reviews praised models with quieter operations, emphasizing the need for a balanced approach to design. Performance is key, but user comfort cannot be ignored.

Another emerging theme was maintenance. About 40% of customers mentioned that regular maintenance was a hassle. Many felt that manufacturer recommendations were not clear or realistic. This feedback underlines the significance of guidance and support from manufacturers. Users want their machines to run efficiently and appreciate detailed maintenance instructions. The combined insights reveal that future CNC mill designs must prioritize user experience and maintainability alongside precision.

Top 10 Small CNC Mills for Precision Machining Needs

| Model | Spindle Speed (RPM) | Travel (X, Y, Z mm) | Weight (kg) | Customer Rating (out of 5) | Price ($) |

|---|---|---|---|---|---|

| Model A | 12,000 | 600 x 400 x 400 | 300 | 4.7 | 2,500 |

| Model B | 10,000 | 500 x 350 x 300 | 280 | 4.5 | 2,200 |

| Model C | 15,000 | 600 x 400 x 500 | 350 | 4.8 | 3,200 |

| Model D | 9,000 | 400 x 300 x 300 | 250 | 4.1 | 1,800 |

| Model E | 11,000 | 500 x 400 x 400 | 320 | 4.6 | 2,750 |

| Model F | 13,000 | 600 x 500 x 500 | 360 | 4.9 | 3,500 |

| Model G | 8,500 | 400 x 400 x 300 | 240 | 4.2 | 1,600 |

| Model H | 10,500 | 500 x 300 x 350 | 300 | 4.4 | 2,200 |

| Model I | 14,000 | 700 x 500 x 600 | 400 | 5.0 | 4,000 |

| Model J | 11,500 | 600 x 450 x 550 | 350 | 4.3 | 3,000 |

Related Posts

-

The Ultimate Checklist for Choosing the Best Mini CNC Mill for Your Business Needs

-

Unmatched Quality: Discover the Best Small CNC Mill from Trusted Chinese Manufacturers

-

Step-by-Step Guide to Mastering Your Home CNC Machine for Creative Projects

-

Unlock Precision: How a Small CNC Mill Transforms Your DIY Projects into Professional Creations

-

Why Horizontal Machining Centers Are Essential for Modern Manufacturing Success

-

How to Choose the Right CNC Metal Machining Service for Your Projects