Blog

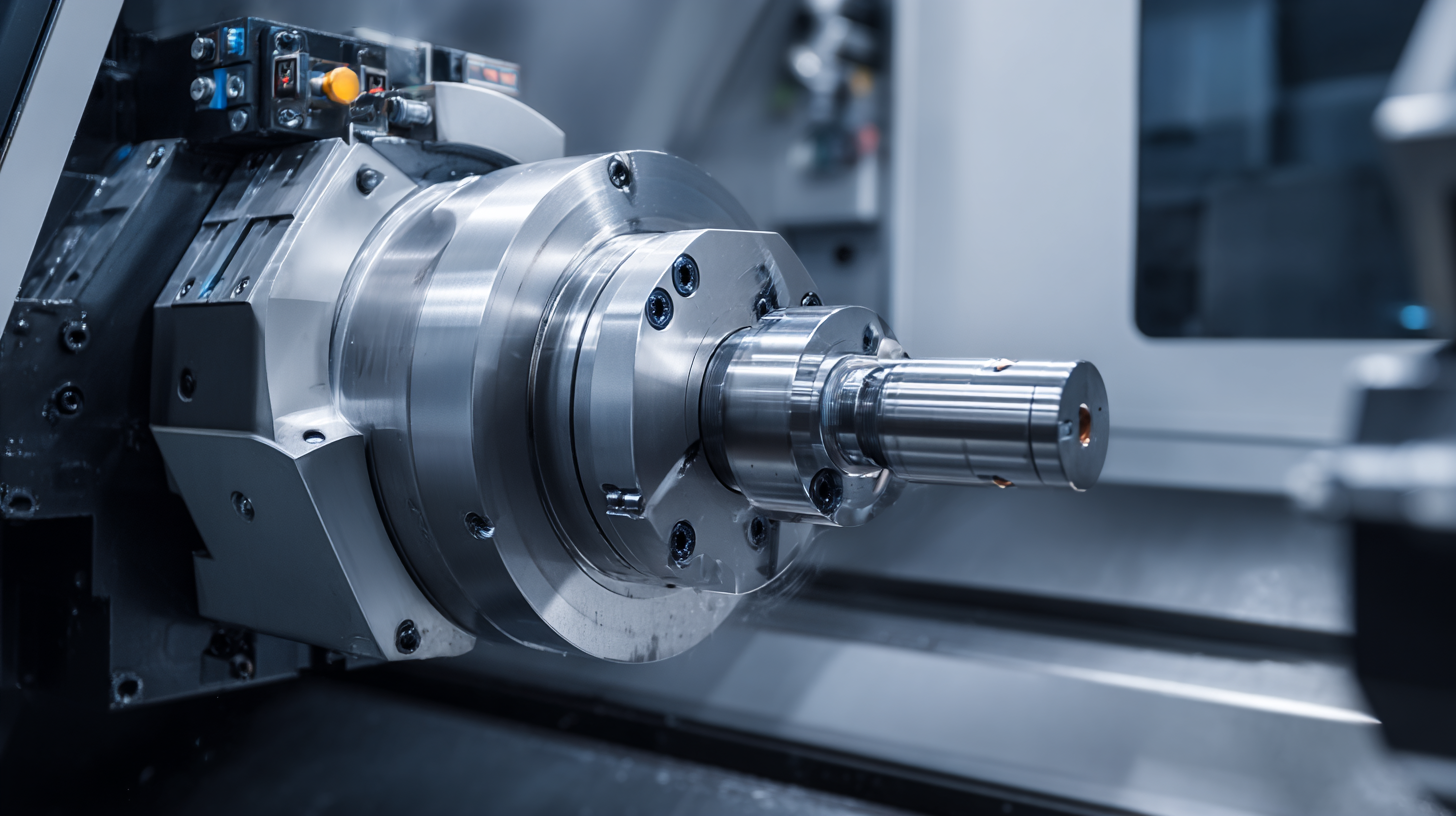

Overcoming Challenges with the Best CNC Lathe Machines for Global Procurement

In the rapidly evolving landscape of manufacturing, the role of CNC lathe machines has become increasingly pivotal in overcoming production challenges and enhancing efficiency. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2026, with CNC lathes being a significant contributor to this growth. These advanced machines not only streamline operations but also offer precision and flexibility that traditional lathes cannot match.

As manufacturers face a myriad of obstacles, from supply chain disruptions to the demand for higher quality products, investing in the best CNC lathe machines emerges as a decisive strategy for global procurement. In this blog, we will explore key tips for selecting and utilizing CNC lathe machines effectively, ensuring that your production processes are not only competitive but also resilient in the face of industry challenges.

The Evolution of CNC Lathe Machines: A Global Overview of Technological Advancements

The evolution of CNC lathe machines has been a significant journey marked by technological advancements that have transformed manufacturing processes across the globe. From manual lathes to sophisticated CNC systems, these machines have adapted to meet the ever-changing demands of precision engineering. The integration of computer numerical control has not only enhanced accuracy but has also expanded the capabilities of lathe machines, enabling them to perform complex tasks with remarkable efficiency.

In recent years, the introduction of advanced materials and smart technologies has further revolutionized CNC lathe machines. Innovations such as predictive maintenance, IoT connectivity, and real-time monitoring have allowed manufacturers to optimize productivity and reduce downtime. These advancements are pivotal in a global procurement landscape, where companies strive for greater competitiveness and sustainability. As the world increasingly embraces automation and Industry 4.0, CNC lathe machines continue to evolve, driving forward the future of manufacturing.

Global CNC Lathe Machine Market Growth 2023-2030

The chart above illustrates the projected growth of the CNC lathe machine market from 2019 to 2030. The data indicates a steady increase in market size as technological advancements and global procurement challenges are addressed. This reflects the evolving landscape of CNC lathe machines worldwide.

Key Features of High-Performance CNC Lathes for Streamlined Manufacturing Processes

As the digital transformation accelerates with the maturity of technologies like 5G, big data, and cloud computing, manufacturers are poised for a revolutionary transformation. The alignment of these technologies with high-performance CNC lathe machines plays a critical role in streamlining manufacturing processes. Key features of these modern CNC lathes include enhanced automation capabilities, real-time data analytics, and seamless integration with advanced manufacturing systems. By leveraging these features, companies can achieve greater precision and efficiency, ultimately driving product quality and reducing waste.

In the context of China's strategic focus on intelligent manufacturing, the implementation of high-performance CNC lathes aligns with the nation's vision to transition from a rapid growth model to one of high-quality development. The integration of smart technologies in manufacturing processes not only boosts productivity but also promotes sustainable practices. As companies adopt intelligent solutions such as automation and digital twins, the era of smart manufacturing dawns, offering unprecedented opportunities for innovation and competitive advantage within the global marketplace.

Global Procurement Strategies: Sourcing the Best CNC Lathe Machines for Competitive Advantage

In today's competitive manufacturing landscape, sourcing the best CNC lathe machines is crucial for gaining a competitive advantage. Effective global procurement strategies not only enhance operational efficiency but also ensure access to cutting-edge technology. By establishing strong relationships with reliable suppliers across various regions, businesses can take advantage of quality machinery that meets their specific production needs. Furthermore, leveraging technology tools such as procurement software can streamline the sourcing process, allowing for better tracking of supplier performance and price negotiations.

When exploring global sourcing options, factors such as cost, machine specifications, and lead times are vital to consider. Businesses must conduct thorough market research to identify the best CNC lathe machines available worldwide. Engaging with industry experts and attending international trade shows can provide valuable insights into the latest trends and innovations. Additionally, adopting a flexible procurement model enables companies to swiftly respond to market changes, ensuring they remain competitive in a rapidly evolving industry. By prioritizing strategic sourcing, manufacturers can navigate challenges, maximize productivity, and ultimately secure a more robust position in the global marketplace.

Overcoming Challenges with the Best CNC Lathe Machines for Global Procurement

| Machine Model | Max Swing Diameter (inches) | Spindle Speed (RPM) | Power (HP) | Features |

|---|---|---|---|---|

| Model A | 15 | 3000 | 10 | CNC Control, High Precision |

| Model B | 20 | 2500 | 12 | Automatic Tool Change, Less Setup Time |

| Model C | 18 | 3200 | 15 | Live Tooling, Enhanced Productivity |

| Model D | 22 | 2000 | 18 | High Durability, Robust Design |

| Model E | 25 | 1800 | 20 | Easy Maintenance, Energy Efficient |

Industry-Specific Applications of CNC Lathes: Maximizing Efficiency Across Sectors

CNC lathes have become indispensable tools across various industries, providing precision and efficiency that traditional machinery struggles to match. In the automotive sector, for instance, CNC lathes are employed to create intricate components such as cylinder heads and camshafts. Their ability to consistently produce high-volume parts with minimal error not only speeds up production but also enhances the overall quality of the vehicles, thereby meeting the rigorous demands of today’s market.

In the aerospace industry, where safety and reliability are paramount, CNC lathes play a crucial role in manufacturing critical parts like turbine rotors and structural components. The precision offered by these machines ensures that each piece meets exact specifications, which is vital for maintaining the integrity of flight operations. Similarly, in the medical field, CNC lathes are used to create surgical instruments and implants with unparalleled accuracy. By tailoring applications to meet the specific needs of each sector, CNC lathes maximize efficiency, reduce waste, and ultimately contribute to the advancement of technology across the globe.

Overcoming Common Challenges in CNC Lathe Operations: Best Practices and Solutions

CNC lathe operations present a unique set of challenges that can hinder productivity and efficiency. According to a report by the Association for Manufacturing Technology, nearly 40% of manufacturers cite downtime due to equipment malfunctions as a primary concern. To mitigate this, implementing best practices such as regular maintenance schedules and operator training can significantly enhance performance. Equip your team with a deep understanding of machine capabilities and limitations to reduce operational errors, which can cost organizations both time and money.

Additionally, optimizing tool selection is crucial for overcoming common CNC lathe challenges. The Manufacturing Institute reports that 70% of machining issues stem from improper tool usage. By selecting the right tools and cutting parameters for specific materials, businesses can reduce wear and tear on equipment and improve product quality. Investing in high-performance tools not only increases efficiency but also extends the lifespan of CNC lathe machines, leading to long-term cost savings in global procurement processes.