Blog

How to Optimize Production with a 5 Axis CNC Milling Machine

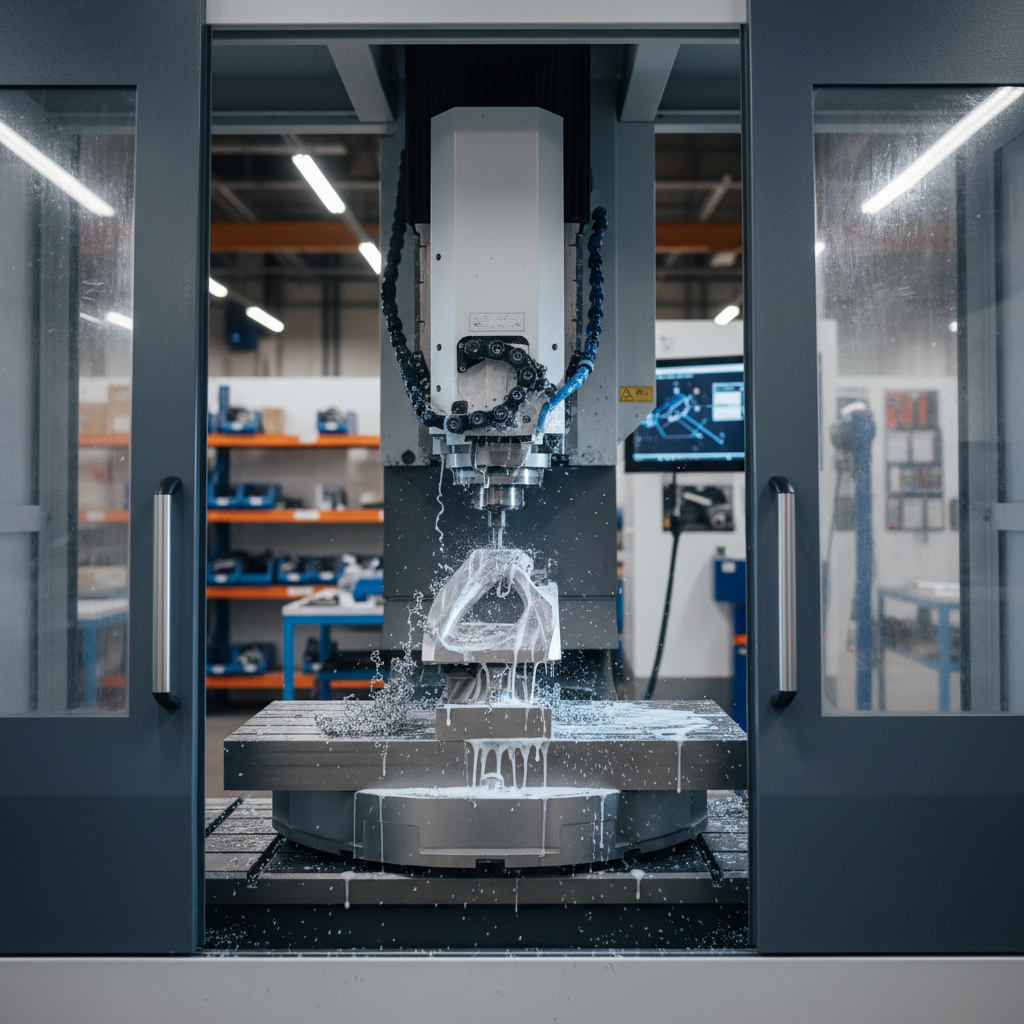

In the fast-evolving landscape of manufacturing, the integration of advanced technologies has become imperative for companies striving to remain competitive. A pivotal innovation in this realm is the 5 axis CNC milling machine, which has significantly transformed production processes. According to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.3 billion by 2025, with the demand for multi-axis machines growing rapidly due to their ability to produce complex geometries with greater precision and efficiency. This evolution is not merely a trend; it is a response to the industry's need for shorter lead times and enhanced product quality.

The capabilities of a 5 axis CNC milling machine allow for continuous cutting, reducing setup time, and enabling the creation of intricate components in a single operation. This technology is becoming indispensable in sectors such as aerospace, automotive, and medical manufacturing, where precision and intricacy are paramount. A report from Grand View Research states that the aerospace segment is anticipated to dominate the CNC machine tools market, primarily driven by the high precision requirements of components. By optimizing production with a 5 axis CNC milling machine, manufacturers not only improve operational efficiency but also gain the flexibility to respond to market demands rapidly, ensuring sustained growth and innovation in a competitive economy.

Understanding the Basics of 5 Axis CNC Milling Machines

5-axis CNC milling machines are revolutionizing the manufacturing landscape by enhancing precision and efficiency in complex machining tasks. Understanding the basics of these advanced machines is crucial for operators and manufacturers alike. A 5-axis CNC milling machine allows for simultaneous movement along five different axes, enabling the production of intricate geometries that were previously challenging or impossible to achieve with traditional milling methods. This capability not only increases dimensional accuracy but also reduces setup times and minimizes the need for multiple workholding fixtures.

Furthermore, the integration of advanced technologies, such as dynamic machining and effective post processors, plays a vital role in optimizing the production process. By using post processors, operators can streamline workflows and ensure the machine's control system understands the intended machining paths. Recent advancements highlight the importance of simulation and verification before machining begins to avoid potential crashes and maintain high reliability levels.

Understanding these fundamentals is essential for maximizing the potential of 5-axis CNC milling machines in today's competitive manufacturing environment.

Key Advantages of Using 5 Axis CNC Milling in Production

The adoption of 5-axis CNC milling machines in production environments has surged over the past few years, driven by their myriad advantages over traditional machining methods. According to a report by MarketsandMarkets, the global CNC machine market is anticipated to reach USD 100 billion by 2026, with 5-axis machines becoming a pivotal segment due to their enhanced capabilities. These machines can perform complex machining tasks in a single setup, drastically reducing production time and minimizing the chance of errors, resulting in higher efficiency and consistency in part quality.

One of the most significant benefits of 5-axis CNC milling is its ability to reduce lead times. A study by the American Machinist highlights that manufacturers utilizing 5-axis technology can decrease cycle times by up to 30%, which is crucial in meeting tight production schedules. Furthermore, the ability to access all sides of a workpiece without the need for multiple setups not only saves time but also enhances accuracy and reduces material waste. This is particularly beneficial in industries like Aerospace and Medical Device Manufacturing, where precision is paramount and even marginal deviations can lead to significant cost increases and safety concerns.

Techniques to Improve Efficiency in 5 Axis CNC Milling

The advent of 5-axis CNC milling technology has revolutionized manufacturing processes by enhancing efficiency and precision in a wide range of applications. One of the primary techniques to improve productivity is through data model-based toolpath generation. By leveraging advanced algorithms to preprocess point cloud data with methods such as four-point denoising and octree techniques, manufacturers can optimize machining operations, reduce cycle times, and increase throughput. This innovative approach ensures that tools follow the most efficient paths, minimizing waste and energy consumption.

Additionally, implementing multi-objective optimization design strategies, such as the Taguchi method, allows for enhanced structural integrity of machine components, significantly impacting machining accuracy and performance. As the demand for complex and high-precision components grows, integrating revolutionary machining techniques not only facilitates intricate designs but also streamlines the overall manufacturing workflow. By focusing on these advanced techniques, industries can fully capitalize on the benefits of 5-axis CNC milling, leading to greater productivity and competitive advantage in the marketplace.

Best Practices for Maintenance and Care of 5 Axis CNC Machines

Proper maintenance and care of 5-axis CNC milling machines are crucial for ensuring optimal performance and longevity. These advanced machines require a routine that encompasses regular inspections, cleaning, and preventive maintenance. Keeping the machine well-lubricated and checking the alignment frequently can prevent costly downtime and enhance precision.

Tips for maintaining your 5-axis CNC machine include establishing a scheduled maintenance plan. This should involve systematic checks of the tool holders, spindle, and workholding setups. Regularly inspect the coolant system for leaks or clogs, and ensure that the filters are cleaned or replaced as necessary to maintain a consistent flow. Additionally, always keep the machine and its surrounding area clean to prevent dust and debris from affecting performance.

Another important aspect of care is software updates. Staying current with the latest software not only improves machine functionality but also enhances compatibility with new tools and materials. Keep a log of any maintenance performed, including software updates, to track the machine's performance over time and preemptively address potential issues.

5 Axis CNC Machine Maintenance Frequency

This chart illustrates the recommended maintenance frequency for 5 Axis CNC machines. Regular maintenance ensures optimal performance and longevity of the machinery.

Implementing Advanced Software for Optimized Milling Processes

To optimize production with a 5-axis CNC milling machine, advanced software plays a crucial role in enhancing the efficiency and precision of milling processes. These software solutions often come equipped with sophisticated algorithms that facilitate complex calculations and simulations, allowing operators to visualize tool paths and identify potential issues before actual machining begins. By leveraging such technology, manufacturers can significantly reduce setup times and minimize material waste, leading to more efficient production cycles.

Moreover, integrating advanced software into the milling process enables seamless communication between the machine and the operator. Real-time data analytics can provide insights into operational performance, allowing for dynamic adjustments and proactive maintenance. This adaptability ensures that the milling process remains optimal, responding to varying production demands without compromising quality. By prioritizing the implementation of advanced software, manufacturers can unlock the full potential of their 5-axis CNC milling machines, ultimately achieving enhanced output and precision in their manufacturing operations.

Related Posts

-

Choosing the Top 7 Features of the Best CNC Milling Machine Manufacturers

-

2025 Industry Trends: Innovative Solutions for Sourcing the Best CNC Metal Milling Machines

-

Ultimate Guide to Choosing the Best 5 Axis CNC Milling Machine for Your Manufacturing Needs

-

Transforming CNC Milling Machine Market Dynamics at China Import and Export Fair 2025

-

Mastering Precision Crafting with the Best CNC Lathe Machine Comprehensive Tutorial for Beginners

-

Overcoming Challenges with the Best CNC Lathe Machines for Global Procurement