Blog

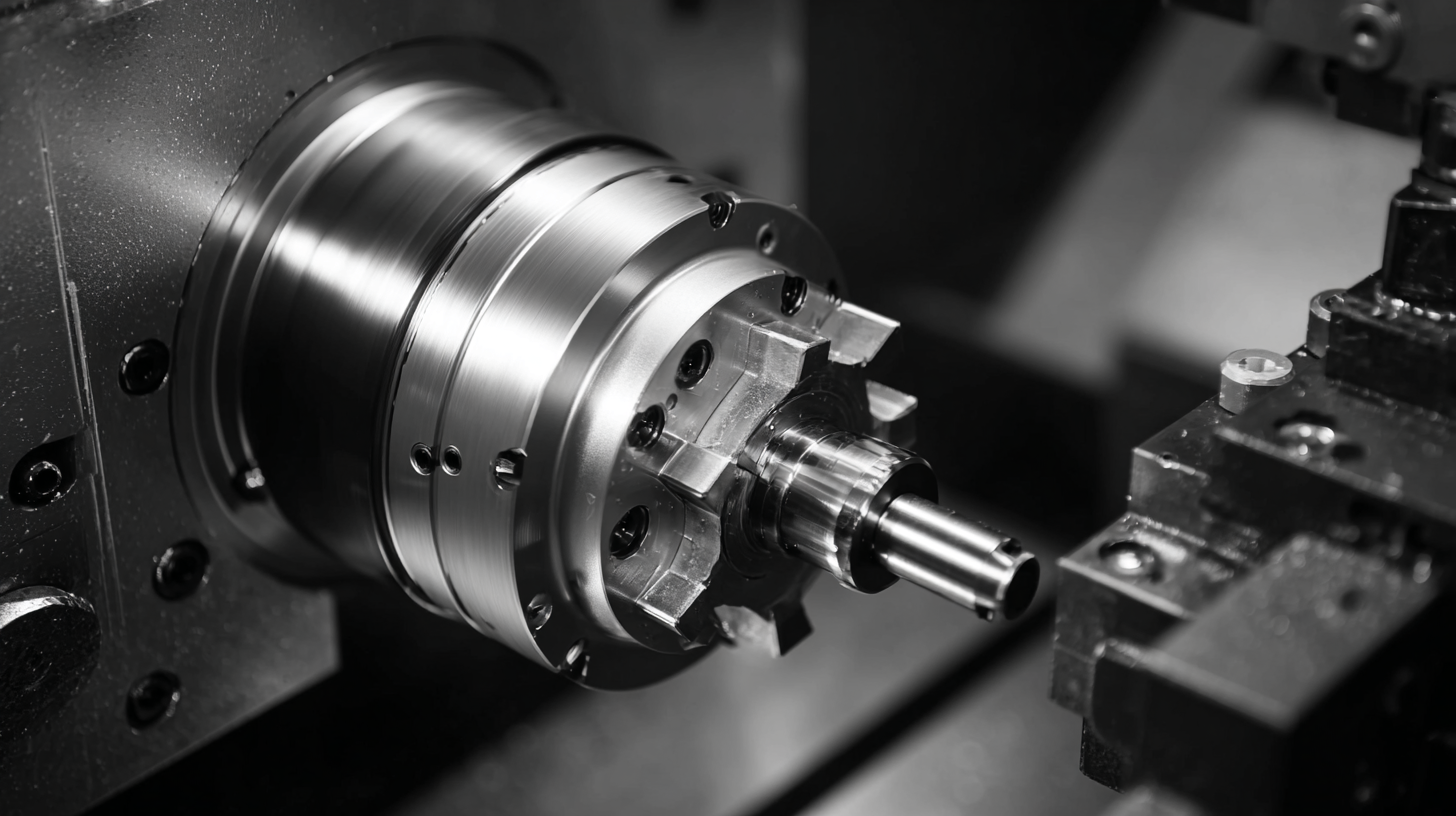

How to Master the Art of CNC Lathe Programming for Precision Machining

In the competitive realm of precision machining, mastering CNC lathe programming is pivotal for achieving optimal performance and precision. According to a report by the International Federation of Robotics, the global market for CNC machines is projected to reach $100 billion by 2025, underscoring the escalating demand for skilled operators proficient in CNC lathe technology. With advancements in automation and software, CNC lathes have transformed traditional machining processes, enabling manufacturers to enhance productivity and reduce waste.

However, to fully leverage these sophisticated tools, operators must grasp the intricacies of CNC lathe programming, which encompasses everything from G-code writing to tool path optimization. As industries continue to evolve, the ability to expertly program CNC lathes will not only improve operational efficiency but also ensure that firms remain competitive in an increasingly automated landscape.

Understanding the Basics of CNC Lathe Programming for Beginners

CNC lathe programming is an essential skill for those looking to enter the field of precision machining. For beginners, understanding the basics of CNC lathe programming involves familiarizing themselves with key concepts such as G-codes and M-codes, which form the foundation of CNC programming. Learning how to manipulate these codes allows programmers to control the lathe's movements and operations effectively. Tutorials and educational resources are crucial for novices, as they provide step-by-step guidance and practical examples to build foundational skills.

CNC lathe programming is an essential skill for those looking to enter the field of precision machining. For beginners, understanding the basics of CNC lathe programming involves familiarizing themselves with key concepts such as G-codes and M-codes, which form the foundation of CNC programming. Learning how to manipulate these codes allows programmers to control the lathe's movements and operations effectively. Tutorials and educational resources are crucial for novices, as they provide step-by-step guidance and practical examples to build foundational skills.

To further enhance learning, various online platforms and courses are now available. Institutions are increasingly offering CNC programming training as part of their curricula, integrating advanced techniques such as programming with user variables. This approach not only aids in creating more flexible and efficient programs but also prepares students for real-world applications. With free courses and resources accessible online, aspiring machinists can gain both theoretical knowledge and hands-on experience, setting them on a path toward mastering CNC lathe programming.

Essential Tools and Software for Effective CNC Lathe Programming

Effective CNC lathe programming is crucial for achieving precision in machining. To get started, you'll need a combination of essential tools and software that enhance your programming capabilities. CNC programming software like Mastercam and Fusion 360 provides user-friendly interfaces and robust functionalities that streamline the design and machining processes. These tools allow for advanced simulation features, helping you visualize the machining operation before actual execution, which can save both time and materials.

Tips: Familiarize yourself with the software's features by leveraging online tutorials or forums. Engaging with a community of practitioners can also provide you with real-world insights and practical advice that enhances your skill set.

Additionally, consider integrating tools like CAD/CAM software into your workflow. These programs not only assist in generating precise toolpaths but also facilitate seamless communication between design and manufacturing phases. The right combination of CAD and CAM software can significantly optimize your workflow, reduce errors, and improve overall efficiency.

Tips: Regularly update your software to take advantage of new features and bug fixes. Establishing a routine for software training ensures that you and your team can adeptly handle the latest programming techniques and tools.

Step-by-Step Guide to Writing Your First CNC Lathe Program

CNC lathe programming is a critical skill for precision machining, enabling manufacturers to create intricate components with high accuracy. To write your first CNC lathe program, begin by familiarizing yourself with the G-code language, which serves as the foundation of most CNC programming. Each command instructs the machine on how to move its tools and work on materials. According to the 2022 Manufacturing Technology Trends report, about 70% of modern manufacturers are leveraging CNC technology to enhance production efficiency and reduce waste.

Tips: Always start with a clear understanding of your design specifications. Break down the machining process into manageable steps, ensuring each operation is defined before coding. Utilize simulation software to test your program and identify potential errors before actual machining. This not only improves accuracy but also saves time and resources.

As you draft your program, pay attention to tool selection and machining parameters. The right tool can significantly impact the precision of the finished product. A recent survey from the American Society of Mechanical Engineers revealed that optimizing tool paths can lead to a 30% decrease in cycle times and a 15% increase in overall productivity. Therefore, investing the time to master CNC lathe programming techniques will yield substantial benefits in your machining projects.

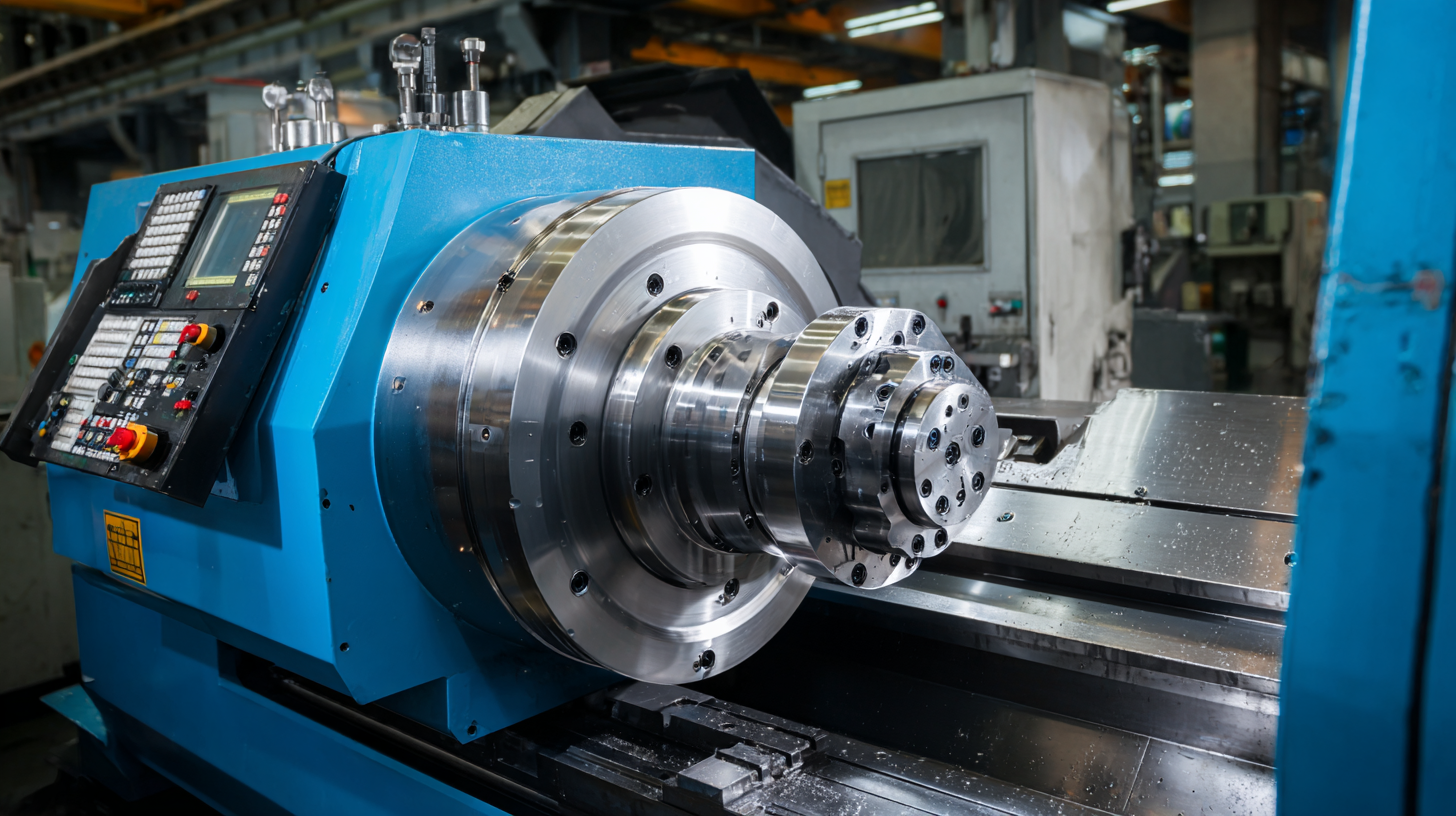

Techniques for Optimizing CNC Lathe Operations and Cycle Time

Optimizing CNC lathe operations is essential for improving precision machining efficiency and reducing cycle times. One effective technique is to utilize advanced tooling strategies that maximize material removal rates while maintaining tight tolerances. By selecting the right tools and optimizing their geometry and cutting parameters, machinists can significantly enhance productivity. Using high-speed machining techniques allows for faster processing, thus reducing overall cycle time without compromising the quality of the finished product.

Another important factor in optimizing CNC lathe operations is the programming aspect. Implementing efficient programming practices, such as using subroutines and canned cycles, can streamline the machining process. This approach minimizes repetitive programming tasks and enhances workflow efficiency. Furthermore, selecting the appropriate feed rates and spindle speeds based on the material being worked on can help minimize wear and extend tool life, leading to a more efficient operation overall. Integrating these techniques leads to improvements not just in cycle time but also in part quality, making CNC lathe programming a critical skill for modern machinists.

How to Master the Art of CNC Lathe Programming for Precision Machining - Techniques for Optimizing CNC Lathe Operations and Cycle Time

| Technique | Description | Expected Improvement (%) | Complexity Level (1-5) | Estimated Setup Time (hrs) |

|---|---|---|---|---|

| Tool Path Optimization | Minimizing the distance the tool travels during machining | 20% | 3 | 1 |

| Feed Rate Adjustment | Optimizing the feed rate for different materials | 15% | 2 | 0.5 |

| Tool Selection | Choosing the right tool for the job to enhance precision and speed | 25% | 4 | 2 |

| Program Simulation | Running simulations to predict and prevent issues before machining | 30% | 5 | 1.5 |

| Cycle Time Analysis | Analyzing and optimizing the entire machining cycle | 20% | 3 | 2 |

Common Mistakes in CNC Lathe Programming and How to Avoid Them

CNC lathe programming is an essential skill for achieving precision machining, but many programmers fall into common traps that compromise their work. One significant mistake is neglecting the importance of simulation before execution. By failing to simulate the machining process, operators risk tool crashes and costly downtime. Always leverage advanced simulation software to visualize the machining path and identify potential collisions before running the program.

Another frequent pitfall involves not properly organizing and documenting the G-code. Disorganized code can lead to confusion and unintended results, especially in collaborative environments. Implementing a standard coding format and thorough documentation not only streamlines the programming process but also minimizes errors during production runs.

**Tips:**

- Always run simulations for CNC programs to catch errors before actual machining.

- Maintain clear and organized documentation of your G-code to prevent mistakes and ensure smooth operations.

- Regularly train on software updates, as new features can offer enhancements to your machining processes.

Common Mistakes in CNC Lathe Programming

Related Posts

-

10 Essential Tips for Maximizing Efficiency with Your CNC Lathe Machine

-

Overcoming Challenges with the Best CNC Lathe Machines for Global Procurement

-

Master Your Craft with the Ultimate Guide to the Best Small CNC Machine for Your Business

-

Ultimate Guide to Choosing the Best 5 Axis CNC Milling Machine for Your Manufacturing Needs

-

How to Choose the Best Small CNC Machine in 2025 with Emerging Technology Trends

-

Maximizing Efficiency: The Advantages of CNC Metal Machining for Global Buyers