Blog

What is a Laboratory Sample Pulverizer and How Does It Work?

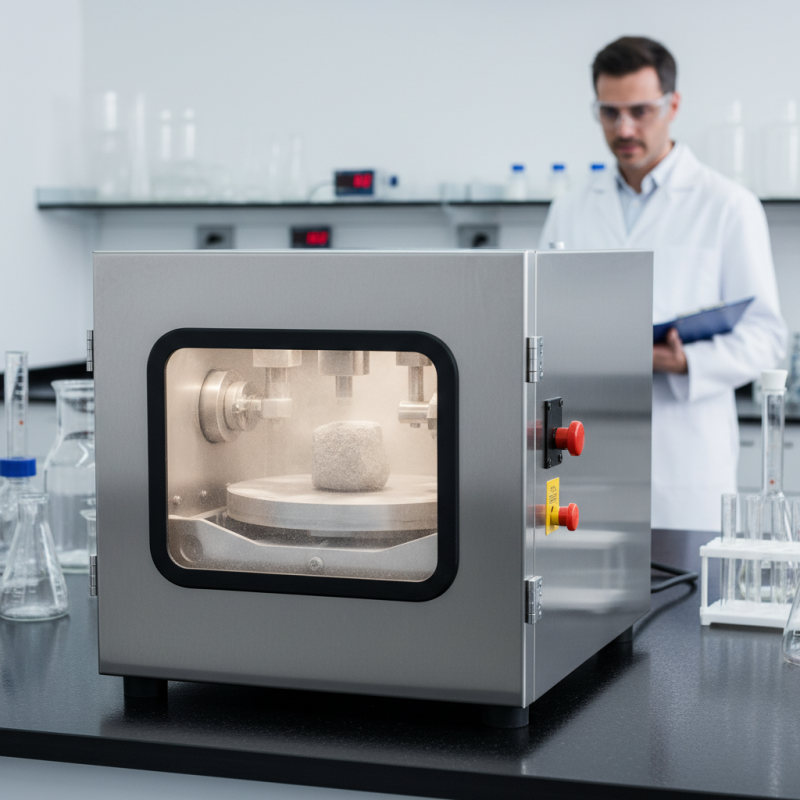

In the world of material testing, the laboratory sample pulverizer plays a crucial role. Dr. Alice Zhang, a leading expert in material sciences, notes, "The precision of sample preparation is vital for accurate results." This device ensures samples are finely ground to achieve uniformity, which is essential for various analyses.

A laboratory sample pulverizer typically works by using high energy to crush materials. This process not only increases surface area but also prepares samples for further examination. It’s fascinating how such a machine can create dust from solid samples. However, operators must consider potential wear on the equipment and ensure proper maintenance.

Yet, there are challenges in using a laboratory sample pulverizer. Different materials may interact unpredictably, leading to inconsistent particle sizes. Moreover, the operator's skill level can impact results significantly. Reflecting on these aspects brings attention to room for improvement in current methods. This highlights the need for ongoing training in sample preparation techniques.

Definition and Purpose of a Laboratory Sample Pulverizer

A laboratory sample pulverizer is a vital tool for researchers. Its primary purpose is to reduce the size of various materials into fine powders. This process facilitates further analysis and testing. Different industries rely on pulverizers for diverse applications, such as metallurgy, pharmaceuticals, or geology.

The operation of a sample pulverizer is relatively straightforward. Typically, materials are placed in a chamber, where they are crushed by mechanical force. The grinding mechanism can vary, but many use blades or balls. Inconsistent particle sizes can result from improper operation. Operators must ensure a uniform sample to obtain accurate results.

Using a pulverizer involves both skill and attention to detail. Factors such as the type of material and desired fineness must be considered. A balance between speed and efficiency is crucial. If the sample is not pulverized enough, it might not yield the information needed. Alternatively, over-processing can lead to contamination. Effective use of a pulverizer often requires practice to perfect the technique.

Laboratory Sample Pulverizer Usage Statistics

This bar chart depicts the number of samples processed by a laboratory sample pulverizer for various materials. The data reflects the efficiency of the pulverizer in different applications.

Common Types of Laboratory Sample Pulverizers and Their Applications

Laboratory sample pulverizers are essential tools in various scientific fields. They help in reducing materials to fine powders for analysis. Common types include jaw crushers, disc mills, and planetary ball mills. Each type has unique features that cater to specific sample types.

Jaw crushers are often used for larger samples. They break down materials by applying force through two plates. This method is effective, but it may create heat. Disc mills, on the other hand, use rotating disks to grind samples. They are ideal for materials that need uniformity. However, they may not handle wet samples well.

Planetary ball mills are versatile machines that can grind and mix samples simultaneously. They provide high-energy collisions, leading to finer particles. Yet, the process can be time-consuming. Understanding these pulverizers' limitations is crucial for effective sample preparation. The choice of equipment should match the specific needs of the research project.

Basic Components of a Laboratory Sample Pulverizer and Their Functions

A laboratory sample pulverizer is essential in many testing environments. It reduces materials to a fine powder for analysis. Understanding its components can enhance performance and ensure reliable results.

The main parts of a pulverizer include the crushing chamber, driving motor, and collection container. The crushing chamber is designed to handle various materials. It uses blades or plates to grind samples. Mixing and homogenizing are crucial during this stage. For instance, reports show that pulverization can improve particle uniformity by up to 30%.

The driving motor powers the machine. It needs to provide consistent torque to handle various materials without stalling. Issues can arise if the motor isn't robust enough. Lastly, the collection container collects the fine powder. Ensuring it is easy to clean can prevent contamination. In many labs, this can be overlooked, leading to cross-sample interference.

Operating Principles: How a Laboratory Sample Pulverizer Works

Laboratory sample pulverizers are crucial in various scientific fields. They grind materials to a fine powder, enhancing analysis and testing. The operating principles are straightforward yet effective. Sample material is placed in a chamber where it is subjected to mechanical forces.

The pulverizer typically utilizes rotating blades or discs to achieve pulverization. As these components rotate, they create a shearing action. This action breaks down the sample into smaller particles. Commonly, a sample can be reduced to less than 100 microns in size. Studies indicate that finer samples generally lead to more accurate analytical results.

However, achieving the perfect grind can be elusive. Some samples may retain larger pieces, impacting testing accuracy. This inconsistency can cause frustration in labs. Operators must regularly check for uniformity to ensure reliable results. Frequent maintenance of the equipment is essential. Calibration may be required to improve performance. Despite these potential challenges, the role of a laboratory sample pulverizer remains indispensable in research and quality control.

What is a Laboratory Sample Pulverizer and How Does It Work?

| Feature | Description | Typical Applications |

|---|---|---|

| Operating Principle | Utilizes mechanical force to crush and grind materials into fine powders. | Material science research, geological samples, and environmental studies. |

| Types of Pulverizers | Ball mill, disc mill, and rod mill variations. | Metallurgical testing, mineral analysis, and chemical applications. |

| Sample Size | Typically processes samples ranging from grams to several kilograms. | Laboratory experiments and quality control assessments. |

| Speed and Efficiency | High rotational speeds and optimized grinding settings enhance performance. | Rapid sample preparation for analysis and testing. |

| Safety Features | Equipped with safety enclosures, overload protection, and emergency stops. | Laboratory environments requiring strict adherence to safety protocols. |

Maintenance and Care for Laboratory Sample Pulverizers

Laboratory sample pulverizers play a crucial role in material analysis. Proper maintenance of these devices is essential for optimal performance. Regular cleaning is important. After each use, residues must be carefully removed. Ignoring this step can lead to contamination. It can also affect the accuracy of future tests.

Additionally, checking for wear and tear on components is key. Blades and grinding surfaces may dull over time. Regular inspections can identify issues early. Replacing worn parts helps maintain efficiency and prolongs the life of the machine. It might seem tedious, but overlooking these tasks can lead to costly repairs.

Lastly, ensuring the pulverizer is properly calibrated is vital. Calibration ensures consistent results. It’s a task that some users might skip due to time constraints. However, it is essential for reliability. If the measurements drift, your data could be flawed, leading to incorrect conclusions. Taking the time for these small but necessary tasks can make a significant difference.