Blog

2026 How to Choose the Best Home CNC Machine for Your Projects?

Choosing the right home CNC machine can be a daunting task. With the global CNC market projected to grow to $113 billion by 2026, the options are overwhelming. Many makers and hobbyists are increasingly interested in home CNC machines for various projects. This technology enables intricate designs, precise cuts, and creative freedom.

When selecting a home CNC machine, consider your specific needs. Are you focusing on woodworking, metalworking, or perhaps 3D printing? Each application requires different machine features. The right machine should fit well within your workspace while maintaining functionality. Some users might overlook machine size and compatibility with materials, leading to frustration later.

Quality is a significant factor as well. Reports indicate that only 30% of home CNC machines meet professional standards in durability and precision. It’s crucial to read reviews and seek recommendations within the maker community. Investing time in research can prevent costly mistakes. Remember, the most expensive machine isn’t always the best choice for your projects.

Understanding CNC Machines: Types and Features

CNC (Computer Numerical Control) machines come in various types, each serving different purposes. Understanding these types is crucial for making an informed choice. The most common types include milling machines, lathes, plasma cutters, and laser cutters. A 2022 industry report indicated that 60% of small businesses use milling machines for their precision work. This shows their popularity and efficiency in various projects.

Features vary significantly among CNC machines. Consider the build quality, user interface, and software compatibility. A report from TechSci Research highlighted that 45% of users prioritize software ease of use when selecting a CNC machine. A complicated interface can lead to frustration and hinder productivity.

Yet, many machines on the market do not cater to this need efficiently, potentially causing long-term issues for users. Another critical aspect is the machine’s footprint. Some models are compact, suitable for small workshops, but may sacrifice features. Others take up more space but offer vast capabilities.

Balancing size and functionality can be tricky. A flawed choice here may lead to wasted space or unmet project needs. Thus, understanding the nuances of CNC machines and their functionalities is essential for every maker.

Determining Your Project Requirements for CNC Machining

When considering a home CNC machine, it’s crucial to assess your project requirements. Start by identifying the materials you plan to work with. Wood, metal, or plastic? Each requires different capabilities. For instance, softwoods are easier to manage than harder materials. This choice often dictates your machine's design and robustness.

Next, think about the size of your projects. Larger items will need a CNC machine with a bigger workspace. Can your garage accommodate it? Is it practical for your needs? A compact machine might save space, but it might limit your creativity. Consider all the dimensions, ensuring you have enough room to operate safely.

Lastly, reflect on your skill level. Beginner-friendly machines simplify tasks but might lack advanced features. If you’re experienced, seek multifunctional options. Too many features can be overwhelming. Balancing ease of use with capabilities is essential. You want to make projects fun, not frustrating. Make a list, weigh your priorities, and dive into CNC machining with a clear vision.

Key Specifications to Consider When Choosing a CNC Machine

When selecting a CNC machine, it's essential to focus on key specifications to meet your project needs. Consider the machine’s working area. A larger workspace allows you to tackle bigger projects. Think about the materials you plan to use. Some machines excel with wood, while others handle metal or plastics better.

Another important factor is precision. Look for details on the machine's precision and repeatability. This information reveals how accurately the CNC can replicate designs. A machine with inconsistent results can lead to frustration and wasted materials. Also, the available spindle speed matters. Faster speeds can improve cutting efficiency but may impair tool longevity.

Don't forget about user-friendliness. Some machines have complex software and controls. If you're not tech-savvy, this could pose a challenge. A steep learning curve can turn a simple project into a daunting task. Lastly, consider support and community resources available. Machines with a loyal user base often provide valuable tips and troubleshooting help. Finding the right balance among these specifications can help refine your choice.

Budget Considerations: Cost vs. Value in CNC Machines

When looking for a home CNC machine, budget plays a crucial role. A lower price might seem appealing. However, it often means sacrificing quality and functionality. Many entry-level machines may lack important features or precision. You might find yourself constantly adjusting them, losing valuable time.

Consider the total cost of ownership. This includes maintenance, repairs, and software. A cheaper machine might cost less upfront but can lead to higher expenses down the line. Therefore, think carefully about what features are essential for your projects. More expensive machines often provide better materials and reliability. They make your projects smoother and save you headaches.

It’s also worth exploring second-hand options. Sometimes, you can find excellent machines at a reduced price. Just ensure you check their condition first. Reflecting on your needs and how often you’ll use the CNC machine is vital. This can help in recognizing the balance between cost and value. In the end, the goal is to make a wise investment that enhances your creativity.

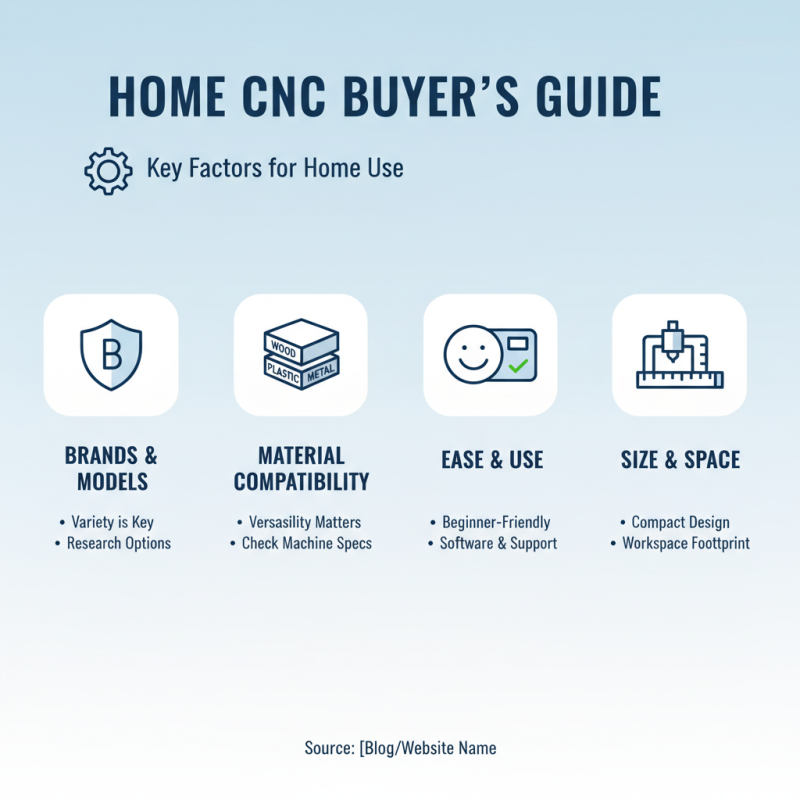

Top CNC Machine Brands and Models for Home Use

When selecting a CNC machine for home use, understanding the variety of brands and models is crucial. Look for machines that accommodate different materials, like wood, plastic, and metal. Some machines have a learning curve, making user-friendliness vital. A compact size can be beneficial, especially if your workspace is limited.

Several brands offer robust entry-level options. These machines often have a solid build and reliable performance. However, some may come with fewer advanced features. This limitation can frustrate experienced users who want to push boundaries. Consider testing different models if you can. Feeling the machine's operation can provide valuable insights into its capabilities and ease of use.

Price is another critical factor. Quality machines can be expensive. However, cheaper alternatives may lack durability or precise functionality. Research and read reviews, but remember that personal experience varies. Finding the right balance between budget and quality may take time. Learning from feedback is essential, especially when models differ significantly in performance.

Related Posts

-

Master Your Craft with the Ultimate Guide to the Best Small CNC Machine for Your Business

-

7 Game-Changing Reasons to Choose a Home CNC Machine for Your DIY Projects

-

Ultimate Showdown of the Best Wood CNC Machines for Your Next Project

-

The Consistent Quality of Trusted Chinese Manufacturers in Best Milling Machines

-

How to Choose the Best Small CNC Machine in 2025 with Emerging Technology Trends

-

Innovative Solutions for Global Sourcing of the Best Milling Machines