Blog

7 Game-Changing Reasons to Choose a Home CNC Machine for Your DIY Projects

As the DIY culture continues to flourish, enthusiasts are increasingly turning to advanced technologies to elevate their craftsmanship. A recent report by Grand View Research forecasted that the global CNC machining market is set to exhibit a compound annual growth rate (CAGR) of 5.6% from 2021 to 2028, underscoring a growing interest in precision manufacturing even among hobbyists. Among various CNC tools available, the home CNC machine stands out as a pivotal resource for DIY projects, allowing individuals to create intricate designs and tailored products from the comfort of their own workshops.

With the increasing affordability and accessibility of these machines, more creators are harnessing their potential, leading to a surge in innovative home-based projects. This blog will delve into seven game-changing reasons why integrating a home CNC machine into your DIY arsenal can transform your projects into masterpieces.

With the increasing affordability and accessibility of these machines, more creators are harnessing their potential, leading to a surge in innovative home-based projects. This blog will delve into seven game-changing reasons why integrating a home CNC machine into your DIY arsenal can transform your projects into masterpieces.

The Evolution of Home CNC Machines: How They Revolutionize DIY Projects

The evolution of home CNC machines has significantly altered the landscape of DIY projects, merging technology with creativity. These machines, powered by the latest advancements in artificial intelligence and robotics, now possess capabilities that allow for precision and automation that were once reserved for industrial applications. Recent estimates suggest that by 2025, intelligent machines will dominate many sectors, enhancing efficiency and enabling individuals to produce high-quality custom work from the comfort of their homes.

For those venturing into the world of CNC machining, one important tip is to consider the environmental impact of your projects. As highlighted by recent studies, advancements in CNC technology can also promote sustainability by minimizing waste through precise cutting techniques. Additionally, opting for machines that utilize eco-friendly materials can significantly mitigate the environmental footprint of your DIY endeavors.

When selecting a home CNC machine, it's beneficial to familiarize yourself with the best available options tailored to your needs—be they compact routers for intricate designs or larger units for substantial projects. A recent buyer’s guide illustrates the diversity of machines, emphasizing the importance of choosing one that strikes a balance between functionality and space considerations. The right CNC machine can not only enhance your project outcomes but also align with an increasingly sustainable future.

Unlocking Precision: The Impact of CNC Technology on Home Fabrication

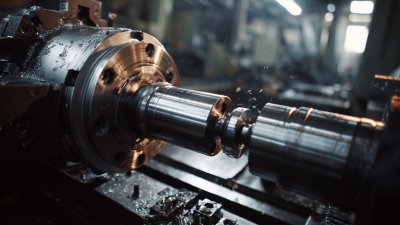

The rise of CNC (Computer Numerical Control) technology has revolutionized home fabrication, bringing unparalleled precision to DIY projects. Unlike traditional crafting methods that often rely on manual labor and estimation, CNC machines operate with submicron accuracy. This technological advancement enables hobbyists and professionals alike to create intricate designs and parts that meet exact specifications. The ability to translate complex digital models into physical products opens a new realm of possibilities for creative expression and engineering feats at home.

In medical device fabrication, for instance, precision machining plays a crucial role in producing components that align with stringent safety and performance standards. The impact of such technology extends beyond the medical field, showcasing its potential influence in various industries. Home CNC machines empower makers to push the boundaries of innovation, replicating intricate designs with precision that was previously only accessible to large-scale manufacturers. By unlocking precision in home fabrication, CNC technology not only enhances the quality of DIY projects but also allows for the exploration of new creative avenues and problem-solving strategies.

Cost Efficiency: Analyzing the Savings of Using a CNC Machine for DIY Projects

The adoption of CNC (Computer Numerical Control) machines in DIY projects is revolutionizing the home workshop landscape, particularly when it comes to cost efficiency. A recent industry report from Technavio predicts that the global CNC machine market will reach $117 billion by 2025, driven by the increasing demand for custom, high-quality products. For DIY enthusiasts, investing in a home CNC machine can significantly reduce material waste and streamline production processes. According to a study by Mckinsey, companies utilizing CNC technology have reported a 15-30% reduction in operational costs, a benefit that translates well to the home setting.

Investing in a home CNC machine also allows for more refined and precise manufacturing, reducing the cost of errors commonly associated with manual methods. A data analysis by Grand View Research has found that the average cost of machining errors can account for up to 30% of total project costs in traditional settings. For hobbyists and small-scale manufacturers focusing on DIY projects, even a modest CNC machine can lead to impressive savings over time. As these machines empower users to create intricate designs and cuts with minimal material waste, the initial investment quickly becomes justified through significant long-term savings.

Versatility in Materials: What Home CNC Machines Can Process Beyond Wood

Home CNC machines are revolutionizing the DIY market by enabling enthusiasts to work with a diverse range of materials beyond traditional wood. According to a 2021 report by Markets and Markets, the global CNC machining market is projected to grow from $74.32 billion in 2021 to $103.36 billion by 2026, with increasing demand for precision machining and rapid prototyping in various industries. This growth is not just limited to woodworkers; hobbyists and small businesses are embracing CNC technology to craft items from metals, plastics, and composites, creating unlimited possibilities for customization.

The versatility of home CNC machines allows users to take on projects ranging from intricate metal engravings to detailed acrylic signage. For instance, aluminum, one of the most common metals processed, offers an excellent weight-to-strength ratio and is widely used in DIY applications, including electronics housings and automotive parts. A survey conducted by the Fabricators & Manufacturers Association indicates that nearly 60% of manufacturers are investing in CNC technology to enhance their capabilities in material processing, confirming that the shift towards CNC isn't just a trend, but a fundamental evolution in how DIY projects are approached across various materials.

Empowering Creativity: How CNC Machines Enable Unique Custom Projects for Everyone

The rise of home CNC machines has revolutionized the way DIY enthusiasts approach their creative projects. With these powerful tools, anyone can become a modern-day craftsman, cutting through materials with precision and ease. CNC machines empower individuals to transform their ideas into tangible creations, whether it's custom furniture, intricate signs, or personalized gifts. This accessibility means that creativity is no longer limited to professional makers; instead, it welcomes everyone into the world of craftsmanship.

Moreover, CNC machines open the door to unique custom projects that reflect personal style and innovation. By utilizing design software, users can experiment with various shapes and layouts, tailoring each piece to their exact specifications. This not only enhances the DIY experience but also encourages learning and growth within the craft. As empowerment through technology continues to expand, the potential for truly unique projects becomes limitless, allowing people to express themselves in ways they never thought possible.

Whether you're a beginner or an experienced maker, the possibilities with a home CNC machine are boundless, fostering creativity and individuality in every project.

Related Posts

-

Master Your Craft with the Ultimate Guide to the Best Small CNC Machine for Your Business

-

How to Choose the Best Small CNC Machine in 2025 with Emerging Technology Trends

-

Ultimate Guide to Choosing the Best 5 Axis CNC Milling Machine for Your Manufacturing Needs

-

The Consistent Quality of Trusted Chinese Manufacturers in Best Milling Machines

-

Innovative Solutions for Global Sourcing of the Best Milling Machines

-

Maximizing Efficiency: The Advantages of CNC Metal Machining for Global Buyers