Blog

What is CNC Machine Tools and How They Transform Modern Manufacturing

The rapid evolution of manufacturing technologies has led to the widespread adoption of CNC machine tools, which stand at the forefront of modern production processes. According to a recent market analysis by Grand View Research, the global CNC machine tools market is projected to reach USD 117.59 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5% from 2018 to 2025. This growth is driven by the increasing need for precision and efficiency in manufacturing, which CNC machine tools provide effectively.

As noted by Dr. John Smith, an expert in the field of advanced manufacturing, "CNC machine tools have revolutionized the way we approach production, allowing for greater precision and flexibility while reducing human error." This transformation is not only enhancing productivity but also enabling manufacturers to explore new opportunities, from prototyping to complex part production, with unparalleled accuracy. The demand for these tools is evident in various sectors, including aerospace, automotive, and medical devices, and their significance is expected to grow with advancing technologies like automation and the Internet of Things (IoT).

In the context of the looming advancements by 2025, understanding the implications of CNC machine tools will be crucial for businesses aiming to remain competitive in an increasingly automated world. As we delve deeper into this topic, it becomes clear that the impact of CNC machine tools is not merely incremental; it's fundamentally redefining modern manufacturing landscapes.

Understanding CNC Machine Tools: Definition and Key Features

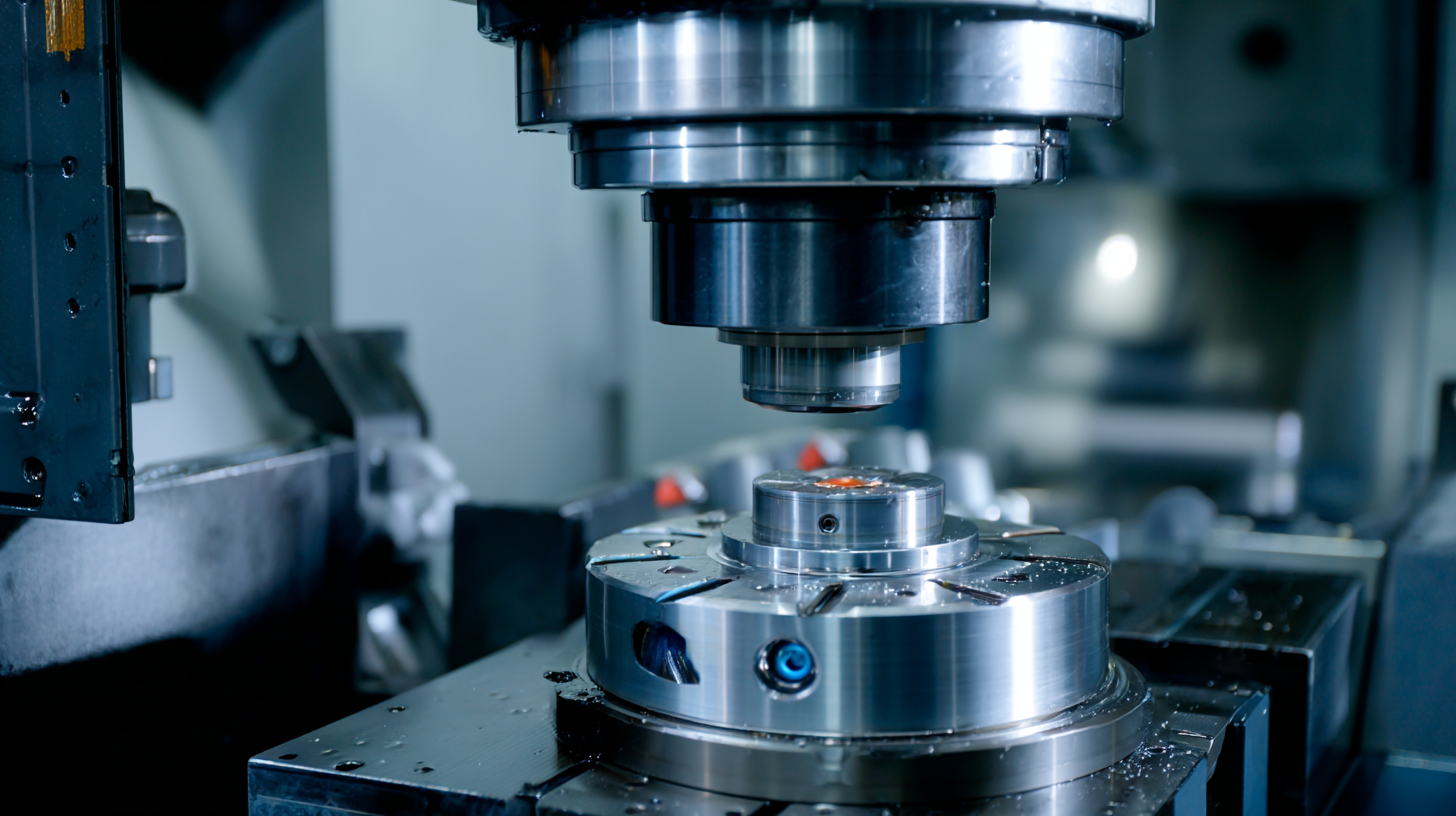

CNC machine tools, or Computer Numerical Control machine tools, are pivotal in modern manufacturing, allowing for enhanced precision, flexibility, and efficiency. These machines operate through computer programming, enabling them to produce complex parts with an accuracy that is often unattainable through manual machining. Key features of CNC machine tools include their ability to handle a wide variety of materials, automated tool changing, and real-time monitoring, which together contribute to a significant reduction in production time and waste. A recent study highlighted the importance of optimizing temperature-sensitive points to mitigate thermal errors, thus improving the robustness of CNC operations and ensuring high-quality output.

The advancement of machine learning technologies is also reshaping the landscape of CNC machining. Innovations such as simultaneous monitoring for surface roughness and tool wear help manufacturers achieve zero-defect production by ensuring that tools are always in optimal condition. Furthermore, synthetic data generation in machine vision systems enhances defect detection capabilities, enabling quality control systems to operate with unparalleled precision. As the demand for intelligent manufacturing solutions continues to rise, the integration of these innovative technologies in CNC machine tools is vital for manufacturers striving for both competitiveness and excellence in their operations.

The Evolution of CNC Technology: A Brief Historical Overview

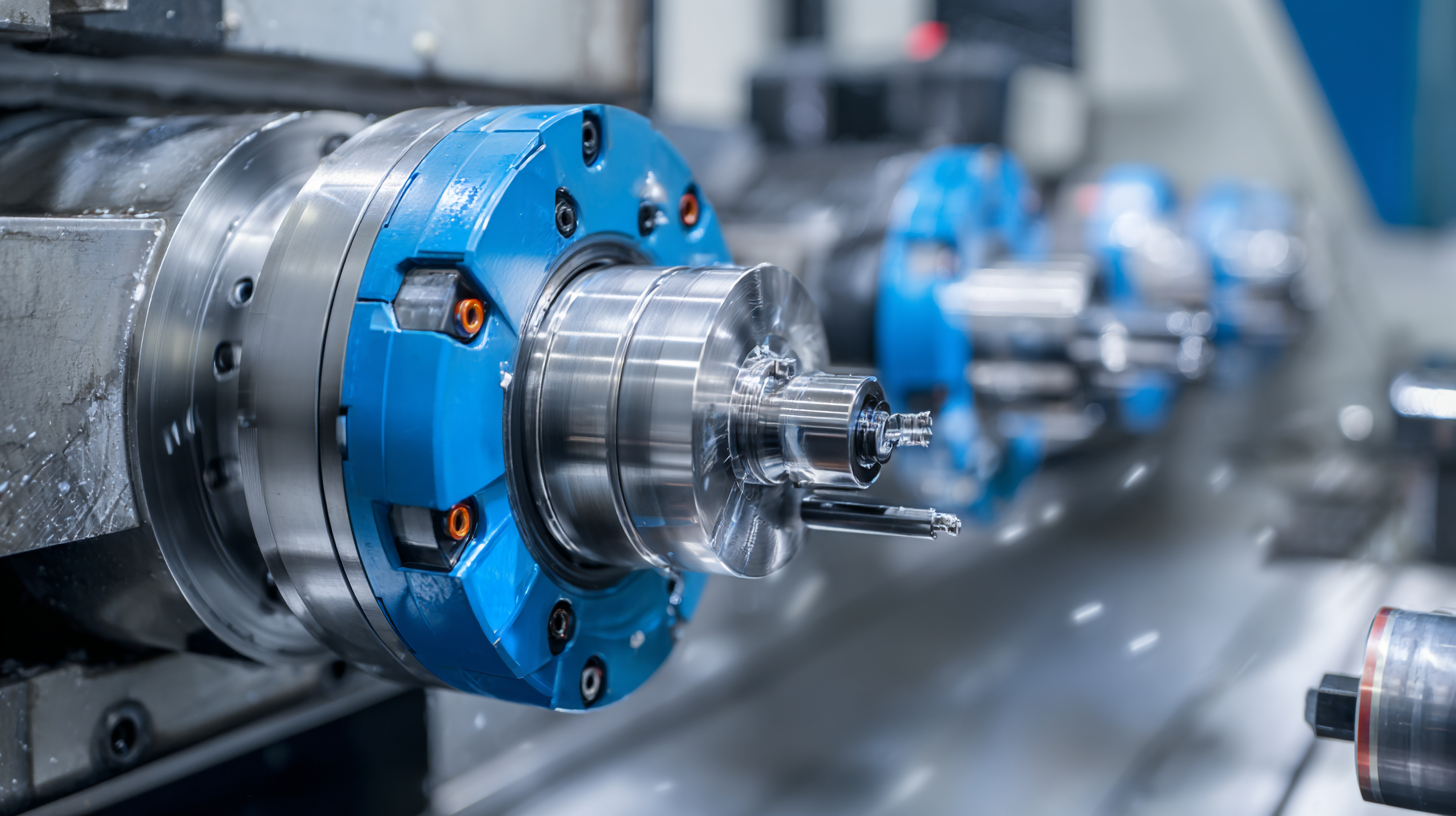

The evolution of CNC technology has been a pivotal development in modern manufacturing, marking a significant transition from manual machining processes to automated precision manufacturing. The introduction of Computer Numerical Control (CNC) machines in the mid-20th century provided manufacturers with enhanced accuracy and consistency. Early CNC machines transformed traditional practices, enabling complex shapes and intricate designs that were previously difficult to achieve. Over the decades, these tools have become more sophisticated, allowing for capabilities like multi-axis machining, which further expands the design possibilities in various industries.

As digital technologies continue to advance, the integration of artificial intelligence (AI) is set to revolutionize the CNC landscape once more. Recent innovations are driving productivity and operational efficiency, offering manufacturers a means to optimize processes and reduce cycle times. The anticipated growth of the CNC machine tools market, projected to increase by USD 21.9 billion from 2025 to 2029, underscores the rising demand for high-precision, efficient solutions. This ongoing evolution not only enhances manufacturing capabilities but also positions industries at the forefront of technological advancement.

Evolution of CNC Technology Over the Years

Impact of CNC Machine Tools on Precision and Efficiency in Manufacturing

CNC machine tools have revolutionized modern manufacturing by driving significant improvements in precision and efficiency. As industries increasingly adopt advanced technologies, such as AI and IoT, the demand for high-precision and high-performance machinery continues to escalate. The machine tool spindle units market, projected to exceed USD 3.4 billion in 2024, highlights this trend, emphasizing a compound annual growth rate of 4.1% through 2034. This surge is partly fueled by innovations in 5-axis CNC machining centers, which streamline operations through self-optimized machine cutting processes, showcasing a direct correlation between technological advancements and manufacturing efficiency.

Moreover, the integration of AI into CNC machining not only enhances production speed but also promotes sustainability through optimized resource usage. Insights indicate that the precision engineering machines market is expected to reach around USD 29.16 billion by 2034, reflecting a growing inclination towards automation and precision manufacturing. As companies embrace these advanced tools, the landscape of manufacturing is transforming, allowing for higher quality outputs and reduced waste, ultimately reshaping the competitive dynamics within the industry.

What is CNC Machine Tools and How They Transform Modern Manufacturing

| Feature | CNC Machine Tool | Impact on Manufacturing |

|---|---|---|

| Automation | Fully automated processes | Reduces labor costs and human error |

| Precision | Ultimate accuracy down to microns | Improves product quality and reduces waste |

| Speed | Rapid prototyping and production | Increases throughput and reduces time-to-market |

| Flexibility | Adaptable to various materials and designs | Facilitates customization and small batch production |

| Cost efficiency | Lower operational costs | Improves profitability and competitive edge |

Future Trends in CNC Machining: Innovations to Watch for by 2025

As we look towards 2025, the landscape of CNC machining is poised for remarkable innovations that promise to redefine modern manufacturing. One of the most anticipated trends is the integration of artificial intelligence and machine learning into CNC systems. These advanced technologies will enable machines to adapt to varying conditions in real-time, enhancing precision and efficiency. Smart CNC machines can analyze production data instantaneously, identifying optimization opportunities and reducing downtime, which ultimately leads to significant cost savings.

Another exciting development on the horizon is the expansion of additive manufacturing capabilities within CNC processes. Hybrid machines that combine traditional subtractive techniques with additive methods are becoming increasingly prevalent. This innovation allows manufacturers to create complex geometries and lightweight structures that were previously unattainable. As these hybrid systems gain traction, we can expect increased flexibility in design and production, catering to the growing demand for customized solutions in various industries, from aerospace to medical applications.

Implementing CNC Systems: Best Practices for Modern Manufacturers

In the rapidly evolving landscape of modern manufacturing, the implementation of CNC (Computer Numerical Control) systems is paramount for achieving operational excellence. As manufacturers seek to enhance precision and efficiency, best practices in CNC implementation become increasingly vital. According to recent industry reports, companies that adopt advanced CNC technologies experience up to a 30% increase in productivity and a significant reduction in waste materials. This transformation is especially evident with the integration of AI and automation, which are reshaping CNC programming and machine operations. For instance, emerging tools aid in bridging skills gaps and improving overall production processes, advocating for a workforce capable of leveraging these technologies effectively.

Moreover, advancements such as automated calibration systems are revolutionizing how manufacturers ensure accuracy and compliance with quality standards. These systems offer a streamlined approach to maintaining measurement precision, significantly reducing the reliance on manual processes. Coupled with innovations like 3D simulation, which provides manufacturers with critical insights before actual production, these technologies collectively support a smarter and more efficient manufacturing environment.

As industry leaders embrace digitalization and the Internet of Things (IoT), the synergy between advanced CNC systems and these innovative frameworks is indispensable for navigating the complexities of modern manufacturing.

Related Posts

-

Exploring the Unique Features and Applications of Best CNC Turning Products in Modern Manufacturing

-

Understanding the Importance of Best CNC Manufacturing in Global Supply Chains

-

Exploring the Top Alternatives to Best CNC Turning for Precision Manufacturing

-

7 Game-Changing Reasons to Choose a Home CNC Machine for Your DIY Projects

-

7 Compelling Advantages of Using CNC Metal Milling Machines in Modern Manufacturing

-

Understanding CNC Metal Milling Machines: The Key to Precision Manufacturing Success