Blog

How to Choose the Right Machining Center for Your Manufacturing Needs

In the evolving landscape of manufacturing, selecting the appropriate machining center has become critical for achieving operational efficiency and product quality. According to a report by the International Federation of Robotics, the global market for machining centers is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028. This increase underscores the rising demand for precision manufacturing across various industries, from aerospace to automotive. With an array of options available—from vertical to horizontal machining centers—manufacturers face the challenge of pinpointing the right equipment that aligns with their specific production needs. By understanding key factors such as material compatibility, production volume, and technological capabilities, businesses can make informed decisions that enhance their productivity and competitiveness in an increasingly automated industry.

Understanding Different Types of Machining Centers and Their Applications

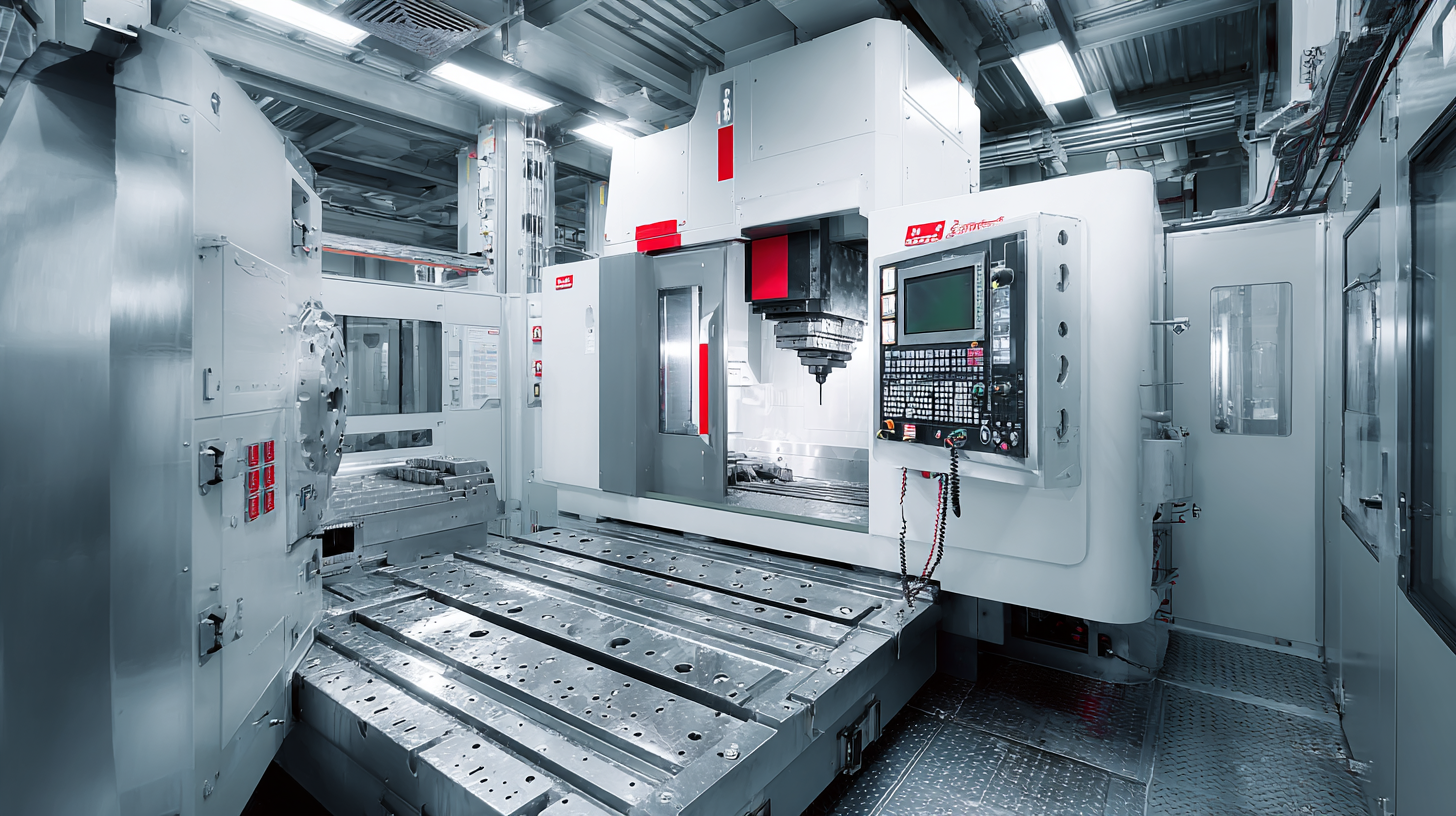

When considering how to choose the right machining center for your manufacturing needs, it’s essential to understand the various types of machining centers and their specific applications. Machining centers can primarily be categorized into vertical and horizontal types, each offering unique advantages. Vertical machining centers (VMCs) are ideal for precision machining with complex geometries and are widely used for materials like aluminum and plastics. In contrast, horizontal machining centers (HMCs) are more suitable for larger workpieces and are efficient for bulk production due to their ability to handle multiple setups without manual intervention.

Moreover, assessing the technological capabilities of these machining centers can significantly enhance production efficiency. For instance, some newer models integrate business intelligence (BI) features that facilitate the analysis of operational data to improve decision-making processes in the manufacturing workflow. These advancements enable manufacturers to leverage actionable insights, improving not only productivity but also product quality. By understanding these differences and technologies, manufacturers can make informed decisions that align closely with their operational goals and market demands.

Key Factors to Consider When Selecting a Machining Center

When selecting a machining center for your manufacturing needs, several key factors must be considered to ensure optimal performance and efficiency. Firstly, the size and weight capacity of the machine are critical; a recent report from the Boston Consulting Group indicates that manufacturing operations often witness a 20% boost in productivity when using machining centers that can handle larger and heavier workpieces. This capacity allows for the processing of complex components without the need for multiple setups, reducing cycle times significantly.

Another important aspect is the technology and tooling compatibility. According to a survey conducted by the International Manufacturing Technology Show (IMTS), 65% of manufacturers agreed that investing in advanced CNC technology and proper tooling directly correlates with improved accuracy and reduced waste during production. This not only enhances the overall quality of the finished products but also aligns with sustainable practices by minimizing material waste.

Finally, consider the ease of maintenance and support offered by the manufacturer. Data from the Association for Manufacturing Technology (AMT) suggests that machines with easily accessible components and comprehensive support options tend to have a 15% lower downtime rate. Prioritizing these factors can lead to long-term gains and operational efficiencies, positioning your manufacturing processes for success in a competitive landscape.

How to Choose the Right Machining Center for Your Manufacturing Needs - Key Factors to Consider When Selecting a Machining Center

| Factor | Description | Importance Level (1-5) | Example |

|---|---|---|---|

| Size and Structure | Consider the physical dimensions and weight capacity of the machining center. | 4 | Vertical vs. Horizontal machining centers |

| Precision | Evaluate the accuracy and repeatability of the machine. | 5 | Tolerances in aerospace components |

| Speed | Assess the spindle speed and rapid traverse rates. | 4 | High-speed machining for production lines |

| Tooling Options | Look into the types of tooling and tool holders available. | 3 | Automatic tool changers |

| Automation Capability | Consider the ability to integrate with automated systems. | 5 | Robotic arms for part handling |

| Software Compatibility | Check for compatibility with CAD/CAM solutions. | 4 | Integration with SolidWorks or Mastercam |

| Cost of Ownership | Evaluate the total cost including maintenance and operation. | 5 | Lifecycle costs vs. initial investment |

Evaluating Production Volume and Efficiency Needs

When selecting the right machining center for manufacturing needs, evaluating production volume and efficiency is crucial. High production volumes often necessitate advanced machinery that can operate continuously and handle large workloads. Businesses with a larger scale generally benefit from enhanced carbon efficiency, as indicated by recent studies assessing the relationship between corporate size and manufacturing carbon emission efficiency. This implies that investing in a machining center designed for high output can lead to more sustainable production practices, ultimately reducing the overall carbon footprint.

Moreover, recent findings suggest that optimizing water and energy usage can significantly boost overall efficiency in manufacturing processes. For instance, employing innovative methods to enhance cold energy efficiency in power generation can result in marked improvements in operational performance. Integrating such efficiency-oriented technologies into your machining center not only maximizes production capabilities but also aligns with global sustainability goals. Thus, when choosing a machining center, it is imperative to consider not only the volume of production but also how the equipment can support energy and resource efficiency in the long run.

Assessing Material Compatibility and Tooling Requirements

When selecting the right machining center for manufacturing, assessing material compatibility is crucial. Recent reports indicate that the global EMI measurement equipment market is projected to grow from approximately $174.6 million in 2025 to $278.78 million by 2033, highlighting the increasing demand for precision instruments in manufacturing. Materials like medical-grade polystyrene are also gaining traction, with innovations enabling manufacturers to leverage material versatility for enhanced production processes.

Moreover, it's essential to evaluate tooling requirements thoroughly. The finite element analysis software market is poised for significant growth, offering specialized tools that facilitate intricate simulations and structural analysis. With a compound annual growth rate of 5.9%, these software solutions are becoming indispensable for engineers aiming to optimize tooling and production strategies. As the landscape of manufacturing evolves with advancements in automation and simulation software, selecting the appropriate machining center that aligns with material and tooling specifications is more important than ever for achieving efficiency and effectiveness in production.

Material Compatibility and Tooling Requirements for Machining Centers

This chart illustrates the material compatibility and tooling requirements for various types of machining centers.

Budgeting for Initial Purchase and Long-Term Maintenance Costs

When selecting a machining center for your manufacturing needs, budgeting for both the initial purchase and long-term maintenance costs is crucial. In the current landscape, businesses are transitioning from experimental AI implementations to strategic actions, emphasizing how budget planning has become a norm. Understanding the total cost of ownership is essential—not just the upfront investment but also the recurring expenses like maintenance, parts, and potential upgrades.

Moreover, as companies encounter fragmented industry and enterprise demands, selecting the right machining center becomes even more critical. A well-defined budget can help streamline the purchasing process. It's not just about acquiring a machine that fits the current production method; it’s about ensuring that future maintenance and operational costs align with the company's financial strategies. Therefore, evaluating different models and their associated long-term costs can lead to informed decisions that enhance productivity without breaking the bank.

Related Posts

-

7 Must Have Features of the Best Machining Center for Your Business

-

Unveiling the Top 5 Technical Specifications of the Best Machining Center for Optimal Performance

-

Maximizing ROI with Top 5 Axis CNC Mills and the Future of After Sales Support and Maintenance Costs

-

Unlocking Efficiency The Advantages of Horizontal Milling Machines in Precision Manufacturing

-

Maximizing Efficiency: The Advantages of CNC Metal Machining for Global Buyers

-

Innovative Solutions for Global Sourcing of the Best Milling Machines