Blog

How to Choose the Right Small CNC Machine for Your Workshop Needs

In recent years, the demand for precision manufacturing has surged, prompting workshop owners to consider the implementation of small CNC machines. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.9 billion by 2026, growing at a CAGR of 6.4% from 2021. This growth underscores the significance of investing in specialized machinery that can enhance productivity and streamline operations, particularly for small to medium-sized enterprises.

When exploring options for small CNC machines, workshop owners must consider various factors, including machine capabilities, material compatibility, and software integration. A recent study by Technavio indicates that the small CNC machine segment is expected to witness substantial growth due to its versatility and efficiency. In a landscape where customization and rapid prototyping are paramount, selecting the right small CNC machine can be a game-changer for workshops aiming to stay competitive in today’s manufacturing arena.

When exploring options for small CNC machines, workshop owners must consider various factors, including machine capabilities, material compatibility, and software integration. A recent study by Technavio indicates that the small CNC machine segment is expected to witness substantial growth due to its versatility and efficiency. In a landscape where customization and rapid prototyping are paramount, selecting the right small CNC machine can be a game-changer for workshops aiming to stay competitive in today’s manufacturing arena.

Ultimately, the decision to invest in a small CNC machine should align with an organization’s specific needs and long-term goals. With advancements in technology and increasing access to user-friendly interfaces, even smaller workshops can harness the power of CNC machinery to elevate their production capabilities and meet the evolving demands of their clientele.

Understanding Your Workshop Requirements for a CNC Machine

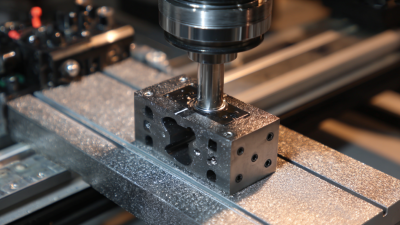

When selecting a small CNC machine for your workshop, the first step is to accurately assess your specific needs. Understanding the types of materials you'll be working with is crucial; different machines are designed to handle various materials, from soft woods to harder metals. Additionally, consider the complexity of the parts you intend to produce. If your projects require intricate designs or high precision, a machine with advanced capabilities such as higher spindle speeds and multi-axis operations may be necessary.

Moreover, think about the available space in your workshop. Small CNC machines vary in size and footprint, and it's important to choose one that fits comfortably without compromising accessibility and safety. Another key factor is your budget; while it might be tempting to opt for the cheapest option, investing in a machine that offers better reliability and support can save costs in the long run. By clearly defining your workshop requirements and aligning them with your anticipated projects, you can make an informed decision that enhances your productivity and efficiency.

Key Features to Consider When Selecting a Small CNC Machine

When selecting a small CNC machine for your workshop, several key features should be carefully considered to ensure it meets your specific needs. First, the machine's size and weight are crucial factors. Smaller machines offer portability, making them suitable for limited spaces, while larger ones may provide more stability and can handle larger workpieces. Additionally, the machine's work area should accommodate the types of projects you intend to undertake.

Another important feature is the cutting technology employed by the CNC machine. Different types of CNC machines, such as routers, mills, and plasma cutters, are designed for various materials and applications. Understanding the materials you plan to work with—whether wood, metal, or plastics—will influence your choice. Additionally, consider the machine's ease of use and software compatibility. User-friendly interfaces and robust software support can significantly reduce the learning curve and enhance productivity in your workshop.

Comparing Different Types of Small CNC Machines Available

When it comes to choosing the right small CNC machine for your workshop, understanding the different types available is crucial. The market offers several options, including CNC mills, lathes, routers, and plasma cutters, each designed for specific applications. According to a report by Research and Markets, the global CNC machine market is projected to reach $100 billion by 2025, reflecting the growing demand for these versatile tools in various industries.

CNC mills are particularly popular for their precision in machining parts from metal or plastic, making them ideal for small-scale production. In contrast, CNC routers excel in cutting softer materials such as wood, composites, and plastics, which can appeal to craft or furniture-makers. A study from the Manufacturing Technology Institute indicates that small CNC routers have seen a 25% increase in adoption among hobbyists and small businesses over the past three years due to their affordability and ease of use. Understanding these distinctions can help you select the best machine to meet your specific workshop needs.

How to Choose the Right Small CNC Machine for Your Workshop Needs

| Machine Type | Max Cutting Area (mm) | Spindle Motor Power (W) | Precision (mm) | Material Compatibility | Price Range (USD) |

|---|---|---|---|---|---|

| CNC Router | 600 x 900 | 1500 | 0.1 | Wood, Plastic, Composite | 1000 - 4000 |

| CNC Lathe | 300 x 600 | 750 | 0.05 | Metal, Plastic | 1200 - 5500 |

| CNC Mill | 500 x 400 | 2000 | 0.01 | Metal, Wood | 2000 - 7000 |

| Laser Cutter | 300 x 400 | 1000 | 0.05 | Acrylic, Wood, Metal | 1500 - 6000 |

| 3D Printer | 250 x 250 | 100 | 0.2 | Plastic, Resin | 200 - 3000 |

Budgeting for Your Small CNC Machine Purchase

When budgeting for a small CNC machine, it’s essential to take a comprehensive approach, considering not only the initial purchase price but also long-term operational costs. According to a recent report by IBISWorld, the CNC machine manufacturing industry has experienced an annual growth rate of 3.2% over the past five years, indicating a robust market that offers various options at different price points. Entry-level CNC machines typically range from $2,000 to $8,000, while mid-range options can cost between $10,000 and $30,000.

Furthermore, operational expenses such as maintenance, tools, and software should also be included in your budget. Research by MarketsandMarkets forecasts the CNC software market to grow from $1.4 billion in 2020 to $2.0 billion by 2025, emphasizing the importance of investing in quality software that enhances the machine's capabilities. It’s critical to account for these recurring costs to create a realistic budget that ensures your investment in a small CNC machine maximizes your workshop's productivity and efficiency over time.

Evaluating Manufacturer Reputation and Support Services

When selecting a small CNC machine for your workshop, evaluating the manufacturer's reputation and support services is crucial. A well-established manufacturer often signifies reliability, with a proven track record in quality and service. Reports from the International Association of Machinists highlight that companies with over 20 years in the industry tend to offer better technical support and warranty services, drastically reducing downtime for users.

Tip: Always research the manufacturer’s history by reading customer reviews and industry publications. Understanding past customer experiences can guide you in selecting a machine that not only meets your technical specifications but also provides ongoing support.

Support services, such as training, maintenance, and readily available spare parts, should weigh heavily in your decision. A survey conducted by the National Tooling and Machining Association found that 65% of CNC machine failures are due to inadequate training. Therefore, choosing a manufacturer that offers comprehensive training programs can immensely benefit your workshop efficiency.

Tip: Ask potential manufacturers about their support policies and training options. A good manufacturer should be willing to provide information on live support, online resources, and detailed manuals.

Related Posts

-

Mastering Precision Crafting with the Best CNC Lathe Machine Comprehensive Tutorial for Beginners

-

Understanding the Importance of Best CNC Manufacturing in Global Supply Chains

-

The Ultimate Checklist for Choosing the Best Mini CNC Mill for Your Business Needs

-

Ultimate Guide to Choosing the Best 5 Axis CNC Milling Machine for Your Manufacturing Needs

-

How to Choose the Best Small CNC Machine in 2025 with Emerging Technology Trends

-

Unlock Precision: How a Small CNC Mill Transforms Your DIY Projects into Professional Creations