Blog

How to Choose the Right CNC Metal Machining Service for Your Projects

When it comes to manufacturing precision parts, choosing the right CNC metal machining service is crucial for the success of your projects. The global CNC metal machining market is projected to reach USD 100 billion by 2026, driven by the increasing demand for customized and high-precision components in industries such as aerospace, automotive, and electronics.

With the rise of advanced technologies, including automation and sophisticated software, businesses are presented with countless options to explore. However, selecting an appropriate service provider requires careful consideration of various factors, such as service quality, capabilities, and compliance with industry standards.

Understanding these elements will not only ensure the delivery of high-quality parts but also enhance overall project efficiency. As the competitive landscape continues to evolve, making informed decisions based on industry trends and reliable data is more important than ever for manufacturers seeking to leverage CNC metal machining effectively.

With the rise of advanced technologies, including automation and sophisticated software, businesses are presented with countless options to explore. However, selecting an appropriate service provider requires careful consideration of various factors, such as service quality, capabilities, and compliance with industry standards.

Understanding these elements will not only ensure the delivery of high-quality parts but also enhance overall project efficiency. As the competitive landscape continues to evolve, making informed decisions based on industry trends and reliable data is more important than ever for manufacturers seeking to leverage CNC metal machining effectively.

Identifying Your Project Requirements for CNC Metal Machining

When embarking on a CNC metal machining project, it is crucial to identify your specific requirements to select the right service provider. Start by assessing the materials you need for your project. Different machining services specialize in various metals, so knowing whether you require aluminum, steel, or titanium will guide your choice. Additionally, consider the complexity of your designs — intricate components might require advanced capabilities and precision.

Tips for choosing a CNC metal machining service include evaluating their technology and machinery. A service that employs modern CNC technology and software can significantly enhance the precision and quality of the finished product. Furthermore, check for the certifications and standards they adhere to, as this speaks volumes about their quality assurance measures.

Don't forget to look at turnaround times and customer support. A reliable service should not only deliver on time but also maintain open communication throughout the process. Engaging with the provider early to discuss your project's specifics can ensure they understand your needs, helping to avoid potential issues later down the line.

Key Factors to Consider When Evaluating CNC Machining Services

When evaluating CNC machining services for your projects, several key factors should be taken into account to ensure you partner with the right provider. First, consider the provider's experience and specialization. According to a 2021 industry report by Grand View Research, the global CNC machining market is projected to reach $100 billion by 2028, reflecting rapid advancements in technology and increasing demand across various sectors. A seasoned service provider will not only have a solid track record but also the expertise in specific materials and processes that are pertinent to your project needs.

Additionally, assess the technology and equipment available at the machining facility. Advanced CNC machines, such as multi-axis CNC milling machines, can enhance precision and efficiency, significantly impacting the quality of the final product. A report from Research and Markets highlights that investments in cutting-edge CNC technology can improve production rates by up to 40% and reduce material waste by around 30%. Therefore, ensuring that your chosen service utilizes state-of-the-art machinery and has professionals trained in the latest techniques can lead to better outcomes for your projects.

How to Choose the Right CNC Metal Machining Service for Your Projects

| Key Factor | Description | Importance Level |

|---|---|---|

| Experience | Years in business and expertise in diverse machining processes. | High |

| Technology | State-of-the-art CNC machines and software capabilities. | High |

| Quality Control | Certifications and processes in place to ensure high standards. | High |

| Customer Support | Availability and responsiveness to customer inquiries and issues. | Medium |

| Lead Time | Time required to complete projects and deliver products. | Medium |

| Pricing | Competitive pricing structures and clarity of cost breakdown. | High |

| Flexibility | Ability to adapt to specific project requirements and changes. | Medium |

Understanding Different CNC Machining Processes and Their Applications

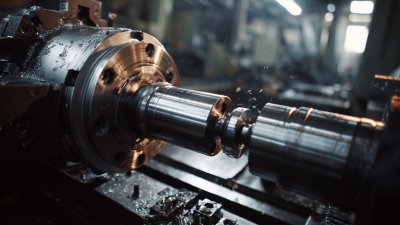

When selecting a CNC metal machining service, it’s essential to understand the various CNC machining processes available and their specific applications. CNC turning and milling are two of the most widely used methods.

CNC turning involves rotating the workpiece against a stationary cutting tool, making it ideal for producing cylindrical parts, such as shafts and fittings. This process ensures high precision and efficiency, making it suitable for low to medium volume production runs.

On the other hand, CNC milling utilizes a rotating tool that moves across the stationary workpiece, allowing for the creation of complex shapes and features. This method is particularly effective for machining flat surfaces, slots, and intricate designs, making it a popular choice for custom parts in industries like aerospace and automotive. Additionally, understanding processes like CNC plasma cutting and waterjet cutting can help you choose the right service for specific materials and thicknesses, optimizing your project's requirements and budget. By familiarizing yourself with these techniques, you can make more informed decisions that align with your project's goals.

Evaluating the Quality and Precision of CNC Machining Providers

Choosing the right CNC metal machining service hinges significantly on evaluating the quality and precision of potential providers. A crucial first step is to assess their technological capabilities. Advanced CNC machines equipped with state-of-the-art software can enhance precision, ensuring that the final product meets stringent specifications. Look for providers that utilize multi-axis machining, which allows for more complex geometries and tighter tolerances, offering a distinct advantage when it comes to accuracy and efficiency.

Another key factor to consider is the provider's quality assurance processes. Reputable CNC machining services will implement thorough inspection methods, such as in-process measurements and final quality checks, to guarantee the consistency and reliability of their parts. Certifications like ISO 9001 can also indicate a commitment to maintaining high standards in quality control. Engaging with past clients and reviewing their feedback on the accuracy of the machining services can provide invaluable insights into the provider’s reliability and craftsmanship.

Cost Considerations: Balancing Quality and Budget in CNC Services

When selecting a CNC metal machining service for your projects, balancing quality with budget is crucial. The cost of CNC machining services can vary widely based on factors such as material type, complexity of the design, and production volume. Understanding these elements can help you make informed decisions that protect your budget while still meeting your quality standards. High-quality machining may come at a premium, but cutting corners can lead to subpar results and increased expenses down the line due to rework or failures.

When considering costs, it is essential to also factor in the total project lifespan. This includes initial planning, research, and compliance with industry standards, especially for projects in regulated sectors. The investment in a robust CNC service that ensures precision and quality can yield long-term savings, making it a wise choice despite higher upfront costs. As you evaluate different CNC providers, prioritize those that offer transparent pricing models and demonstrate a commitment to quality, ensuring you achieve a favorable balance between cost and performance for your machining needs.

Related Posts

-

Maximizing Efficiency: The Advantages of CNC Metal Machining for Global Buyers

-

The Consistent Quality of Trusted Chinese Manufacturers in Best Milling Machines

-

7 Game-Changing Reasons to Choose a Home CNC Machine for Your DIY Projects

-

Understanding CNC Metal Milling Machines: The Key to Precision Manufacturing Success

-

Unveiling the Top 5 Technical Specifications of the Best Machining Center for Optimal Performance

-

7 Compelling Advantages of Using CNC Metal Milling Machines in Modern Manufacturing