Blog

How to Choose the Best Metal CNC Machine for Your Needs?

Choosing the right metal CNC machine can significantly impact your production quality and efficiency. As renowned industry expert John Smith once stated, “The perfect CNC machine for your needs is one that understands your unique requirements.” This highlights the importance of tailoring your selection to specific applications.

Consider the range of available options. There are various sizes, capabilities, and technologies in the market. Each metal CNC machine has distinct strengths. Some excel in precision, while others focus on speed. Often, users prioritize speed but overlook accuracy. This can lead to costly mistakes.

Reflecting on your needs is essential. Think about the types of metals you will work with. Specific machines perform better with harder materials. Your choice should not only depend on current projects but also future goals. Regularly reassessing your machinery may also lead to improvements.

Understanding Your CNC Machine Requirements

When choosing a metal CNC machine, understanding your specific requirements is crucial. Begin by noting the materials you will work with. Different metals, such as aluminum or stainless steel, require different capabilities. Think about the thickness and size of the materials as well. This information will help narrow down your options.

Tip: List your projects and their requirements. This can clarify your needs. Will you be creating intricate parts or large sheets? Defining this will guide your CNC machine choice.

Next, consider the precision you require. Are your projects high-tolerance pieces, or are they simpler designs? The level of detail directly impacts the machine's capabilities. Sometimes, people overlook this and regret their decision later. It’s essential to balance your budget with the accuracy you need.

Tip: Research the resolution specs of potential machines. Take time to compare them thoroughly. You might find that a slightly more expensive model offers better performance in the long run. Reflect on your production volume. Higher production may warrant a more robust machine.

Key Features of Metal CNC Machines to Consider

When selecting a metal CNC machine, several key features demand attention. One important aspect is the machine's rigidity. A rigid machine holds the workpiece steady, which reduces vibrations during cutting. Vibration can lead to inaccuracies. Ensure the frame is robust and well-constructed.

Another critical feature is the spindle speed. A higher spindle speed can increase productivity; however, it may also lead to overheating. Balancing speed and cooling is essential. Consider your material type and thickness. Different materials require specific speeds for optimal results.

Additionally, the software compatibility plays a significant role. A user-friendly interface can simplify operation. Look for a machine that supports common CAD/CAM programs. Some users find certain interfaces confusing. Ensuring ease of use can save time and reduce frustration.

Ultimately, careful evaluation of these features will help in making an informed decision.

Comparing Different Types of Metal CNC Machines

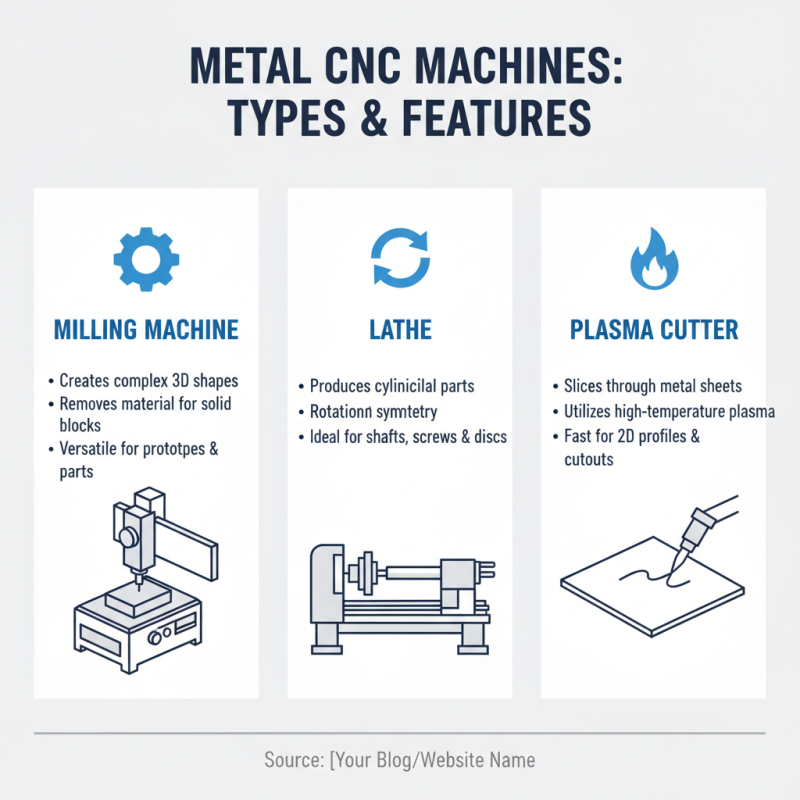

When comparing different types of metal CNC machines, it's essential to understand their unique features. There are three main types: milling machines, lathes, and plasma cutters. Milling machines are versatile. They can create complex shapes by removing material from a solid block. Lathes, on the other hand, are designed for rotational symmetry. They excel at producing cylindrical parts. Plasma cutters provide a different approach. They utilize high-temperature plasma to slice through metal sheets.

Each machine has its strengths and weaknesses. High-precision milling requires skilled operators to avoid mistakes. Even a slight error can ruin a project. Lathes are easier to operate but may lack versatility. They are limited to round shapes, which can be restrictive for some designs. Plasma cutters work fast and are suitable for thick materials but can leave rough edges. Users often find themselves pondering. Which machine meets their needs best?

Budget considerations play a major role, too. Entry-level machines may not offer required precision for all projects. It’s worth exploring used options, though they can come with hidden issues. Observing others' experiences can help guide choices. Reflecting on these aspects will aid in making a sound decision.

Evaluating Budget and Cost Factors

Evaluating the budget is crucial when choosing a metal CNC machine. Initial costs can vary significantly based on features, size, and precision. According to industry reports, a basic CNC machine can cost around $10,000, while high-end models may exceed $100,000. Understanding your requirements can help narrow down options.

Maintenance and operational expenses should also be factored in. These costs may include tooling, software, and service contracts. Regular maintenance can add up, so it's wise to set aside 10-15% of the purchase price annually. Many users overlook this aspect. It can lead to unexpected financial strain down the road.

Another important consideration is operational efficiency. A cheaper machine may save money upfront but could cause delays. Downtime impacts productivity and, ultimately, profitability. Some studies suggest that more efficient CNC machines can return up to 25% in savings on production time. Always weigh initial costs against long-term benefits. Balancing these elements can lead to a more informed decision.

How to Choose the Best Metal CNC Machine for Your Needs?

Maintenance and Support for CNC Machines

Maintenance is crucial for the longevity of CNC machines. Regular upkeep can prevent costly downtime. According to a recent industry survey, about 30% of CNC operators reported unexpected machine failures due to poor maintenance. A simple routine check could avoid these issues.

Understanding the manufacturer's support offerings is vital. Some manufacturers provide extensive training sessions. However, many users may not take advantage of these resources. In fact, nearly 40% of CNC operators admitted to limited knowledge of their machine’s capabilities. This gap in training leads to inefficiencies and safety risks.

Additionally, consider the availability of parts. A report indicated that 25% of CNC machine maintenance issues stem from delayed access to spare parts. Connecting with reliable suppliers ensures smoother operations. Regular maintenance schedules should also be prioritized. This commitment can significantly increase machine reliability and productivity over time.

Related Posts

-

Innovative Solutions for Your CNC Metal Milling Machine Needs

-

How to Choose the Right CNC Metal Machining Service for Your Projects

-

Exploring the Advantages of CNC Metal Machining in Modern Manufacturing Processes

-

Choosing the Top 7 Features of the Best CNC Milling Machine Manufacturers

-

5 Amazing Benefits of Using Horizontal Milling Machines in Modern Manufacturing

-

Unveiling Innovations in Horizontal Machining Centers at the 138th Canton Fair 2025: A Data-Driven Insight