Blog

How to Choose a Small CNC Machine for Metal Work?

Choosing the right small CNC machine for metal work is crucial for any workshop. It’s a decision that can impact production quality and efficiency. According to industry expert, John Smith, “Investing in a small CNC machine for metal can transform your metalworking capabilities.” His insight highlights the importance of making informed choices.

When selecting a small CNC machine for metal, consider the specific needs of your projects. Size and capabilities matter. For example, if you often work with intricate designs, a machine with high precision is vital. Additionally, pay attention to the software included. User-friendly software can significantly reduce learning curves.

However, challenges exist in this process. What works for one project may not suit another. It’s essential to reflect on your long-term goals. Sometimes, a less expensive model might seem appealing, but it could lack durability. Balancing budget with quality is a common dilemma. Thus, careful evaluation is necessary for achieving the best results in metalworking.

Understanding the Basics of Small CNC Machines for Metal Work

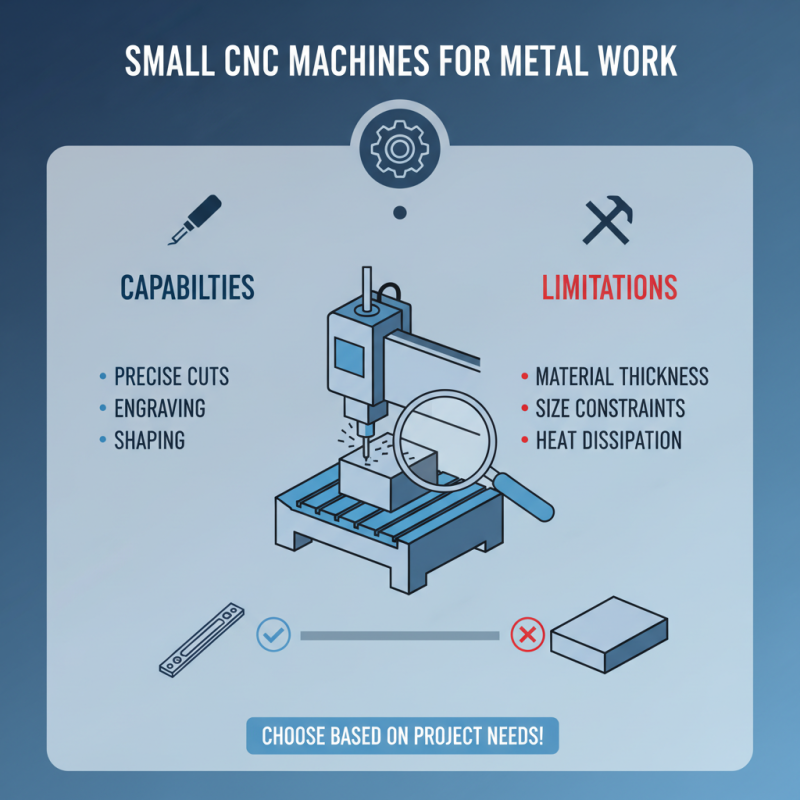

Understanding small CNC machines for metal work involves grasping their capabilities and limitations. These machines can perform precise cuts, engravings, and shapes, but they also come with challenges. For example, the size of the machine affects the material it can handle. Some small CNC machines may struggle with thicker metals. It's crucial to know the type of projects you want before investing.

Another important detail is the learning curve. While many machines offer user-friendly interfaces, mastering CNC programming can take time. Mistakes can happen, especially when working with intricate designs. A beginner may find it frustrating to achieve the desired accuracy right away. Finding a machine that offers good support and resources can make a difference.

Noise and vibration can be other factors to consider. Small CNC machines might not be as stable as larger models, leading to imperfect finishes. Make sure your workspace can accommodate these aspects. Balancing budget, functionality, and space is often tricky. Understanding your specific needs will help in making a more informed choice.

Key Features to Look for in a Small CNC Machine

When selecting a small CNC machine for metal work, several key features should be considered. One vital aspect is the spindle speed. Spindle speed significantly affects the machine's cutting efficiency and precision. According to industry reports, machines with spindle speeds exceeding 20,000 RPM provide smoother finishes and faster processing times for metals.

Another feature to look for is the machine's travel size. Compact machines typically have smaller work areas, but this should match your project requirements. For small components, a travel size of 12" x 12" is often adequate. However, larger pieces may require more space. It’s essential to evaluate what projects you realistically plan to execute. Poor planning can lead to limitations in your machining capabilities.

Consider the control type as well. Machines that offer both manual and CNC capabilities offer flexibility. Some users may prefer hands-on experience, while others might favor automation. Balancing ease of use with precision can be challenging. According to surveys, 40% of users wish they had chosen machines with more intuitive control systems. Look for features that support both, giving you room to grow in your machining skills over time.

Performance Comparison of Small CNC Machines for Metal Work

Assessing Your Metalworking Needs and Projects

When selecting a small CNC machine for metalworking, assessing your projects is crucial. Start by identifying the types of materials you will work with. Aluminum, steel, and titanium have distinct machining requirements. According to industry reports, around 40% of home workshop owners prefer working with aluminum due to its lightweight and ease of machining.

Consider the size of your projects. A compact machine is ideal for intricate parts, while larger projects may need more workspace. Many users find themselves limited by their machine’s capacity. Hence, estimating your workspace requirements helps avoid regrets later on.

Tip: Always factor in future projects when choosing a CNC machine. What else might you want to create in the next year?

Next, explore the machine's precision capabilities. Tolerance levels can range from ±0.005 inches to ±0.0001 inches, depending on the model. A machine with higher precision may come at a premium but is worth it for intricate designs. Do not overlook the software that drives the machine. A user-friendly interface can save time and reduce frustrations, especially for beginners.

Tip: Research user reviews regarding software reliability. A seamless experience in design transfer is vital.

Finally, think about the machine's adaptability. Technology in CNC machining evolves rapidly, and your machine should accommodate upgrades. Stay informed about the latest advancements to ensure your investment remains relevant.

Evaluating Budget and Cost-Effectiveness in CNC Machines

When selecting a small CNC machine for metal work, evaluating budget and cost-effectiveness is crucial. Data shows that CNC machines range from $2,000 to $10,000, depending on features. The initial cost is important, but consider how much you can save in the long run through efficiency. A lower-priced machine may lack precision, leading to higher production costs due to errors.

Tips: Look for machines with a one-year warranty. This can provide peace of mind and protect your investment. Additionally, consider used machines. They can be significantly cheaper and often still in good condition.

Don’t overlook maintenance costs. A machine that requires frequent repairs can quickly negate savings from a low purchase price. Analyze the long-term costs associated with each option. Aim for a balance between initial investment and durability.

Compare specifications against your needs. Sometimes, a slightly more expensive machine may offer long-term savings through reduced waste. Be mindful of the hidden costs, such as tooling and setup time. These factors can impact your overall budget and should not be ignored.

How to Choose a Small CNC Machine for Metal Work? - Evaluating Budget and Cost-Effectiveness in CNC Machines

| Machine Model | Price ($) | X-axis Travel (mm) | Y-axis Travel (mm) | Z-axis Travel (mm) | Max Spindle Speed (RPM) | Cost-Effectiveness Rating |

|---|---|---|---|---|---|---|

| Model A | 4500 | 300 | 200 | 150 | 12000 | 8/10 |

| Model B | 5500 | 400 | 250 | 200 | 10000 | 7/10 |

| Model C | 6000 | 350 | 180 | 120 | 15000 | 9/10 |

| Model D | 7000 | 360 | 220 | 170 | 11000 | 8.5/10 |

Maintenance and Support Considerations for CNC Users

When selecting a small CNC machine for metal work, maintenance and support become crucial. Users should prioritize understanding the machine's upkeep needs. Regular maintenance can prevent costly repairs and downtime. This includes cleaning, lubrication, and software updates. Many users underestimate the importance of a clean workspace. Dust and debris can affect performance over time.

Consider also the availability of technical support. A reliable support system can help resolve issues quickly. Some machines may come with online resources or community forums. This can be a mixed bag. Some users may not find the answers they need. Response times can vary significantly across different manufacturers. Think about whether you’re comfortable troubleshooting on your own.

Documentation is critical. Clear manuals and maintenance logs can guide you effectively. Without these, users may struggle with complex repairs or setups. It’s not unusual to feel overwhelmed when things go wrong. Reflect on past experiences. What did you wish you had when facing challenges? Taking time to evaluate support resources is essential. This can save you from future headaches.

Related Posts

-

The Ultimate Checklist for Choosing the Best Mini CNC Mill for Your Business Needs

-

How to Optimize Production with a 5 Axis CNC Milling Machine

-

Top 10 Small CNC Mills for Precision Machining Needs?

-

Maximizing Efficiency: The Advantages of CNC Metal Machining for Global Buyers

-

Trusted Quality: Discover the Best 5 Axis CNC Mill from China for Global Excellence

-

Transform Your Workshop with High Precision CNC Lathe Technology