Blog

Why You Should Choose a Mini CNC Mill for Your DIY Projects

When embarking on DIY projects, the significance of having the right tools cannot be overstated. Among the myriad options available, a mini CNC mill stands out as an exceptional choice for both hobbyists and seasoned makers alike. This compact machine combines precision with versatility, empowering users to bring their creative visions to life, whether they are crafting intricate designs or producing functional components. The mini CNC mill's ability to handle a variety of materials, from wood to metal, allows for unparalleled experimentation and innovation without the need for extensive workshops or costly equipment.

In a world where the maker movement is gaining momentum, investing in a mini CNC mill can dramatically expand your capabilities. Its user-friendly interface and adaptable settings make it accessible for beginners while also offering advanced features for experienced users. The compact size does not compromise on power; rather, it allows individuals to integrate high-quality machining into their home or small studio environments. This makes the mini CNC mill not just a tool, but a gateway to endless possibilities for creating unique, tailored projects right from the comfort of your workspace. Whether you are a hobbyist looking to refine your craft or a DIY enthusiast aiming for precision, the mini CNC mill is an invaluable addition to your toolkit.

Benefits of Using a Mini CNC Mill for DIY Projects

When embarking on DIY projects, choosing the right tools can significantly influence the outcome. A mini CNC mill offers a range of benefits that make it an attractive choice for hobbyists and professionals alike. Firstly, these machines are compact and versatile, allowing for fine detail work in smaller workshop environments. Whether you're crafting intricate designs or creating customized parts, a mini CNC mill delivers precision that is often unmatched by hand tools.

Additionally, mini CNC mills are user-friendly, making them accessible even for those who may be new to machining. Many models come equipped with straightforward software that simplifies the programming process, allowing you to focus more on creativity rather than complex setups. This ease of use encourages experimentation, enabling enthusiasts to learn and improve their skills rapidly.

Tips: To make the most of your mini CNC mill, start with simple projects to familiarize yourself with the machine’s capabilities. Invest time in learning the software to unlock its full potential, and always prioritize safety by wearing appropriate protective gear while operating the equipment. Regular maintenance and practice will also help enhance the mill's performance and longevity.

Key Features of Mini CNC Mills for Hobbyists

Mini CNC mills have gained immense popularity among hobbyists for their compact size and versatile functions. With the growing DIY culture, statistics from a recent industry report indicate that the mini CNC mill market is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2022 to 2027. This growth highlights a strong interest in milling technology catered specifically towards home-based and amateur projects.

One of the key features that make mini CNC mills attractive is their precision. Most mini CNC mills offer an impressive accuracy of up to ±0.01 mm, allowing enthusiasts to create intricate designs and prototypes that rival those produced by larger industrial machines. Additionally, their user-friendly software interfaces enable even beginners to quickly learn and operate these machines. Coupled with affordability, as many models are priced under $2,000, hobbyists can easily invest in high-quality equipment without straining their budgets. Their compact size also means they can fit into a standard workshop or garage, making them an accessible option for those just starting in the field of CNC machining.

Furthermore, mini CNC mills are designed with versatility in mind, capable of working with a range of materials including plastics, woods, and light metals. This adaptability allows hobbyists to experiment across different projects, from crafting personalized gifts to intricate mechanical parts. According to the American Machinist, about 40% of small business owners in the manufacturing sector have started exploring CNC machining for custom project needs, confirming a shift in DIY practices that leans heavily towards these efficient machines.

Comparing Mini CNC Mills to Traditional Machining Tools

When comparing mini CNC mills to traditional machining tools, several significant advantages emerge, especially for DIY enthusiasts and small-scale manufacturers. Mini CNC mills offer unparalleled precision, allowing for tolerances as tight as ±0.001 inch, which is a remarkable feat compared to conventional tools that often have larger tolerances due to manual operation. According to industry data, around 70% of machinists report improved accuracy and reduced material waste when transitioning from traditional methods to CNC technology, highlighting the efficiency mini CNC mills bring to the table.

Furthermore, mini CNC mills are exceptionally user-friendly and require less space, making them ideal for smaller workshops and home studios. Unlike traditional machining tools that can be cumbersome and demand extensive setup time, mini CNC mills operate with simple software programs that allow users to input designs directly. This streamlined process can cut production times by up to 50%, according to recent studies in machine tool technology. The reduction in setup and programming times enables DIYers to focus more on creativity and less on the complexities of machining.

In terms of cost, mini CNC mills also provide an economical alternative. A report from the Metalworking Industries Association stated that small-scale manufacturers can save up to 30% on operational costs by switching from traditional machining tools to CNC systems. This affordability, combined with advanced capabilities, makes mini CNC mills a compelling choice for those engaged in DIY projects, empowering them to achieve professional-level results without the significant investment typically associated with larger, traditional machinery.

Comparison of Mini CNC Mills and Traditional Machining Tools

Tips for Choosing the Right Mini CNC Mill for Your Needs

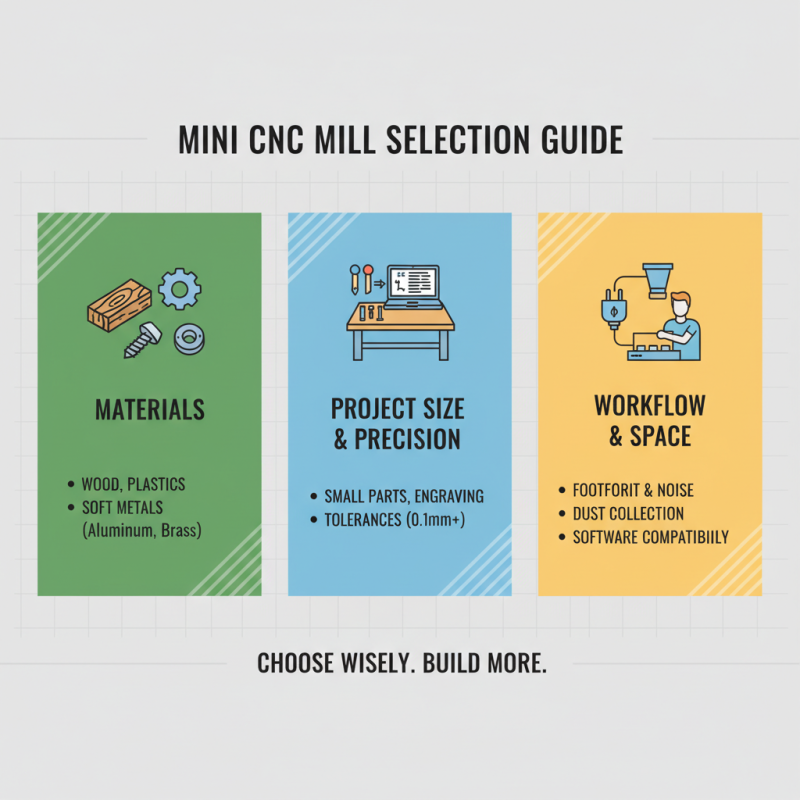

When selecting the right mini CNC mill for your DIY projects, it's essential to consider your specific needs and how the machine will fit into your workflow. Begin by assessing the types of materials you plan to work with. Not all mini CNC mills are equipped to handle various materials, so ensure that the machine you choose is compatible with woods, plastics, or metals, based on your project requirements.

Another crucial factor is the machine's specification, including cutting area, spindle speed, and precision. A larger cutting area allows for more extensive workpieces, while a higher spindle speed can enhance cutting efficiency for tougher materials. Precision is key for achieving detailed designs, so be sure to look for a mini CNC mill that offers high accuracy and repeatability.

Lastly, consider the overall ease of use and support that comes with the machine. Some mini CNC mills come with user-friendly software and comprehensive instructions, making them ideal for beginners. Additionally, check for available community support or resources online, as these can be invaluable when troubleshooting or enhancing your skills. By keeping these tips in mind, you'll be well-equipped to choose the perfect mini CNC mill for your DIY endeavors.

Common Applications of Mini CNC Mills in DIY Projects

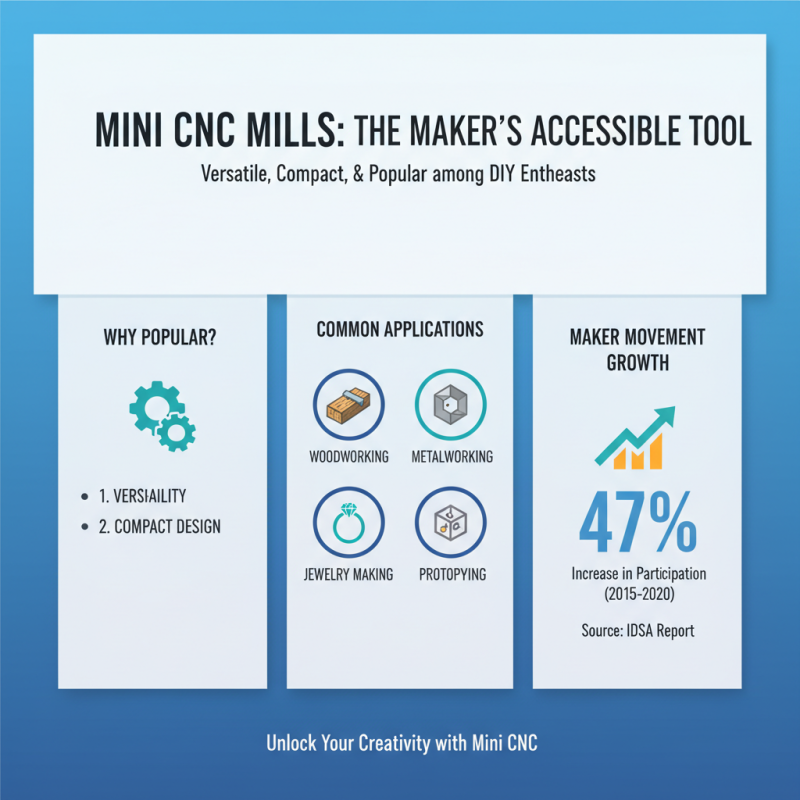

Mini CNC mills have become increasingly popular among DIY enthusiasts due to their versatility and compact design. Common applications for these machines include woodworking, metalworking, jewelry making, and prototyping. With the rise in the maker movement, which according to a report by the Industrial Designers Society of America (IDSA), saw a participation increase of 47% between 2015 and 2020, the mini CNC mill serves as an accessible tool for hobbyists and professionals alike.

Woodworking projects benefit significantly from mini CNC mills, allowing users to create intricate designs and precise cuts that would be challenging to achieve by hand. For metalworking, these mills can handle various materials such as aluminum and plastics, enabling the production of small parts for more complex projects. Jewelry makers use mini CNC mills for detailed engraving and designing unique pieces, enhancing creativity while saving time. Additionally, prototyping for product development can be expedited with rapid and accurate fabrication of components from different materials.

*Tips:* When using a mini CNC mill, always ensure proper tooling and maintenance for accuracy. Regularly inspect your machine for wear and tear, and keep your workspace clean to avoid contamination in your projects. Moreover, start with simpler designs to familiarize yourself with the machine's capabilities before tackling more intricate applications.

Related Posts

-

5 Amazing Benefits of Using Horizontal Milling Machines in Modern Manufacturing

-

7 Must Have Features of the Best Machining Center for Your Business

-

Exploring the Unique Features and Applications of Best CNC Turning Products in Modern Manufacturing

-

Trusted Quality: Discover the Best 5 Axis CNC Mill from China for Global Excellence

-

2025 Industry Trends: Innovative Solutions for Sourcing the Best CNC Metal Milling Machines

-

Mastering Precision Crafting with the Best CNC Lathe Machine Comprehensive Tutorial for Beginners