Blog

How to Choose the Best Small CNC Machine in 2025 with Emerging Technology Trends

As we move into 2025, the landscape of manufacturing technology is evolving rapidly, driven by innovations that enhance efficiency and precision. Among these advancements, the demand for small CNC machines has surged, with market research indicating a projected growth rate of 6.2% CAGR in the global CNC machine market, reaching an estimated value of $95 billion by 2025. Small CNC machines, known for their compact size and versatility, are becoming increasingly popular among hobbyists, startups, and established manufacturers alike, as they enable intricate designs without requiring extensive space.

As emerging technology trends such as automation, IoT integration, and AI-powered software continue to shape the industry, understanding how to select the best small CNC machine for your specific needs is crucial. This blog will guide you through the essential factors and trends to consider, ensuring that your investment aligns with future manufacturing demands and technological advancements.

Key Features to Look for in a Small CNC Machine in 2025

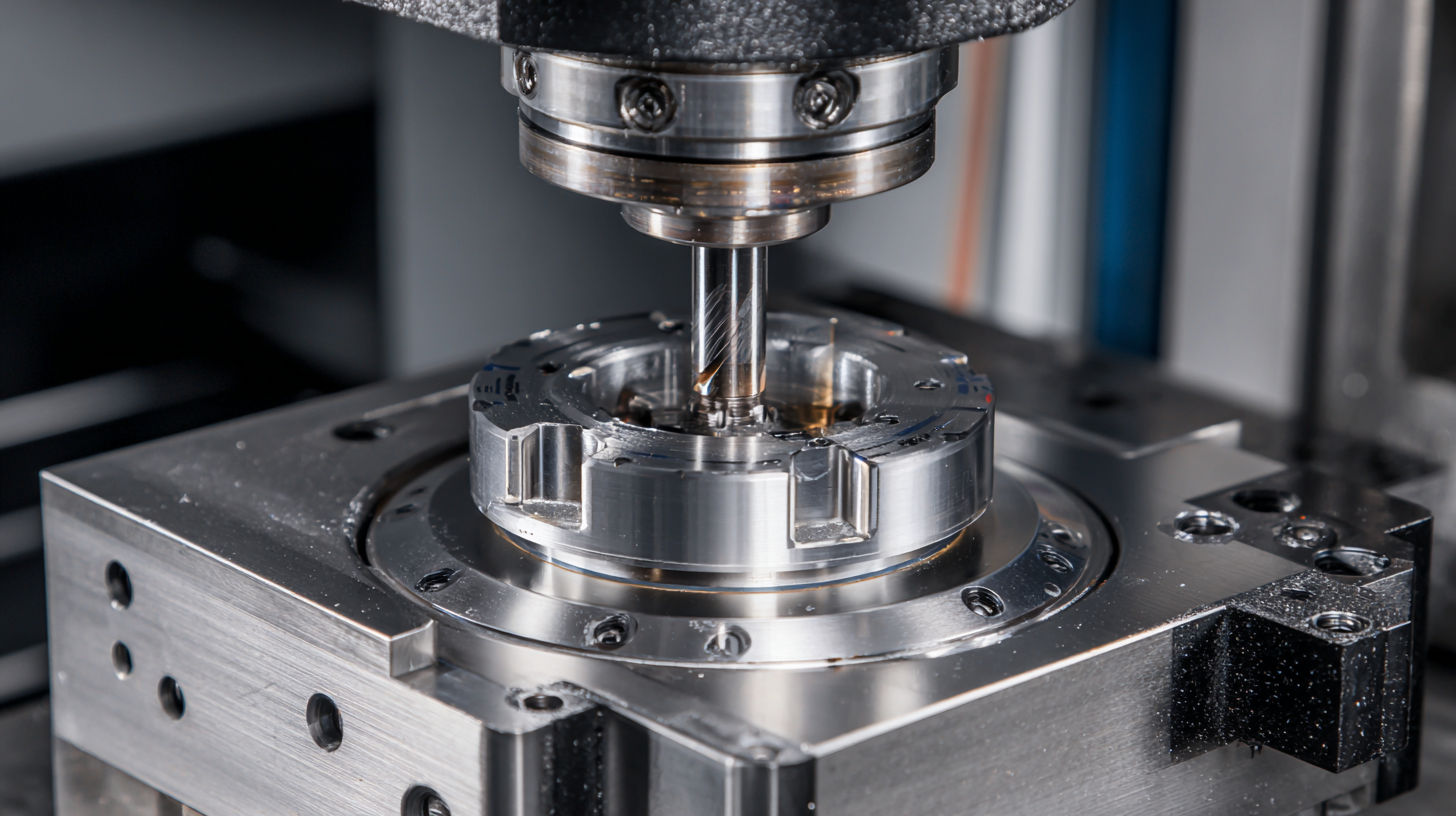

When selecting a small CNC machine in 2025, there are several key features to consider that align with emerging technology trends. First and foremost, precision and automation capabilities have become increasingly important. Machines equipped with advanced sensors and AI-driven algorithms provide enhanced accuracy, allowing for intricate designs without the risk of human error. Look for machines that include real-time monitoring systems, which not only improve the quality of work but also reduce downtime through predictive maintenance.

Another crucial factor is compatibility with various materials. In 2025, small CNC machines should not only work well with traditional materials like wood and metal but also be versatile enough to handle modern composites and biodegradable materials. This adaptability is essential for businesses looking to innovate and maintain sustainability. Lastly, consider user-friendly software integration. As the technology landscape evolves, ensuring that your CNC machine can seamlessly connect with design software and other tools will enhance your workflow and productivity. These features are vital for any savvy buyer looking to invest in a small CNC machine that meets the demands of the modern manufacturing landscape.

Emerging Technologies Impacting CNC Milling and Machining

The manufacturing industry is experiencing a revolutionary transformation driven by digitalization, IoT, and AI technologies. According to recent data, the Global CNC Machine Tools Market is projected to grow significantly, with an increase of approximately USD 24.91 billion from 2020 to 2024, spurred by innovations in CNC machinery that enhance efficiency and precision. Such technological advancements allow manufacturers to integrate smart automation and connectivity into their operations, resulting in improved productivity across various sectors.

Emerging technologies like AI and IoT are playing pivotal roles in this evolution. These technologies enable the development of data model-based toolpath generation techniques which utilize point cloud models for CNC milling machines. This method not only enhances accuracy in machining tasks but also reduces waste and production time. As the industry embraces these innovations, the adoption of modern metal additive manufacturing technologies further exemplifies the shift towards a more agile and responsive manufacturing environment. The focus on employing cutting-edge machining technologies signifies a commitment to both operational excellence and employee welfare, creating a more robust ecosystem for all stakeholders involved.

Trends in Small CNC Machine Adoption (2025)

This bar chart illustrates the predicted trends in the adoption of small CNC machines in 2025, highlighting the growing emphasis on automation, advanced materials, and IoT integration as key factors driving the industry forward.

Comparative Analysis of Popular Small CNC Machines in 2025

When it comes to selecting the best small CNC machine in 2025, a thorough comparative analysis is essential to navigate the expanding market. With the global CNC machine market projected to reach $195.59 billion by 2032, understanding the features and capabilities of various models will help you make an informed decision. Key players in the industry are continually innovating, focusing on precision, speed, and user-friendly interfaces to cater to the needs of both hobbyists and professionals.

**Tip 1:** Look for machines that offer advanced features such as automatic tool changers and enhanced software compatibility, which can significantly improve workflow efficiency. Checking for customer reviews and expert recommendations can also provide insight into the machine's reliability and performance.

When evaluating different small CNC machines, consider the specific applications you plan to use them for. **Tip 2:** Evaluate the machine's build quality and the materials it can handle. Higher quality construction will support more demanding tasks, while versatility in material handling (like wood, plastic, or metal) can extend the machine's usability across various projects. By prioritizing these factors, you can better align your choice with your creative and production goals.

How to Choose the Best Small CNC Machine in 2025 with Emerging Technology Trends - Comparative Analysis of Popular Small CNC Machines in 2025

| Machine Type | Max Working Area (mm) | Spindle Power (W) | Positioning Precision (mm) | Material Compatibility | Price Range (USD) |

|---|---|---|---|---|---|

| Desktop CNC Router | 600 x 400 | 300 | 0.05 | Wood, Plastic, Soft Metals | $1,200 - $2,500 |

| Mini CNC Milling Machine | 500 x 300 | 500 | 0.03 | Aluminum, Brass, Plastic | $800 - $1,800 |

| CNC Laser Cutter | 800 x 600 | 40 | 0.01 | Wood, Acrylic, Leather | $2,500 - $5,000 |

| CNC Plasma Cutter | 1,200 x 1,200 | 1,000 | 0.15 | Steel, Aluminum, Copper | $3,000 - $7,000 |

Understanding Software Compatibility for Small CNC Machines

When selecting a small CNC machine in 2025, understanding software compatibility is crucial for maximizing its functionality and ease of use. The right software can significantly enhance your machining capabilities, streamline operations, and ensure that you can work on diverse projects efficiently. Look for machines that support popular CAD/CAM software, such as Fusion 360 or SolidWorks, which can help you design and implement complex projects with precision.

Tip: Always check the manufacturer's specifications for software compatibility. Some CNC machines may have proprietary software that could limit your options or require additional training. Ensuring that your chosen machine is compatible with the tools you're already familiar with or plan to use will save you time and frustration in the long run.

Additionally, consider the machine's ability to integrate with modern technology trends, such as cloud computing and IoT. These advancements can offer real-time monitoring and remote access capabilities, enhancing production efficiency. Machines that easily connect with cloud-based applications will allow you to manage workflows and data analysis seamlessly.

Tip: Before making a final decision, seek out user reviews and forums to gain insights into others' experiences regarding software compatibility and performance. This can provide valuable information about the practicality of the software integration, which is often not fully conveyed in product descriptions.

Cost-Effective Solutions: Budgeting for Your Small CNC Purchase

When considering a small CNC machine purchase in 2025, budgeting plays a crucial role. The small CNC machine market is projected to grow at a CAGR of 5.3% from 2023 to 2028, with price points ranging significantly, often from $2,000 to over $20,000 depending on features and capabilities. Understanding your budget early can help narrow down your choices and identify machines that provide the best value without overextending finances.

Tip: Consider what features are essential for your projects. Machines that offer multi-functionality or higher precision might come at a premium, but if you mainly require basic capabilities, there are cost-effective models that can meet your needs without unnecessary expenditures.

Research shows that the average small business spends roughly 10-15% of its annual revenue on equipment. Therefore, it’s essential to factor in ongoing operational costs, such as maintenance and tooling, which can add up over time. This insight allows you to plan not just for the initial purchase but also for sustained investment in your CNC setup.

Tip: Explore financing options such as leasing or payment plans, which can ease the initial financial burden while still allowing you to access advanced technology. This way, you can invest wisely without sacrificing essential business cash flow.