Blog

How to Choose the Best Horizontal Machining Center for Your Needs?

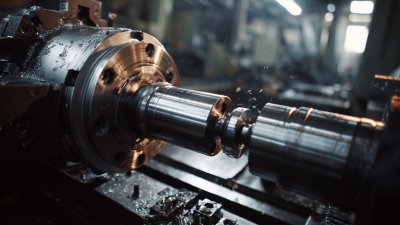

Choosing the right horizontal machining center is crucial for your manufacturing needs. The market is filled with options, making the selection process overwhelming. A horizontal machining center excels in handling complex parts with precision. Its design allows for efficient chip removal, which is vital for high-volume production.

When considering a horizontal machining center, there are key factors to examine. Think about the size of parts you plan to produce. Do you require extended tooling capabilities? Evaluate the machine's axis capabilities and its reliability. These aspects directly impact your efficiency and cost-effectiveness.

The choice is not just about features. Understand your specific needs and production goals. Be aware that each option has its limitations. Assessing your requirements might reveal gaps in what you originally considered essential. A machine may have advanced capabilities but could fall short in daily operations. Prioritize what truly matters for your workflow, and make an informed decision.

Understanding Horizontal Machining Centers and Their Applications

Horizontal machining centers are vital in modern manufacturing. They excel in precision machining and are ideal for complex parts. With a horizontal orientation, they allow gravity to aid chip removal, enhancing efficiency. According to a market analysis by ResearchAndMarkets, the global horizontal machining center market was valued at $5.2 billion in 2023, and it is expected to grow steadily.

These machines are widely used in industries such as aerospace and automotive. Their ability to handle heavy materials makes them suitable for producing intricate components. However, choosing the right one requires careful consideration. Not all horizontal machining centers are the same. Some may lack certain features, which could impact productivity.

It's crucial to assess your specific needs and production volumes. Many users report unanticipated challenges when integrating new equipment. Compatibility with existing systems and tools is often overlooked. Regular maintenance and operator training are essential for maximizing utilization. Understanding these machines and their applications can significantly enhance manufacturing capabilities, but it requires a nuanced approach.

How to Choose the Best Horizontal Machining Center for Your Needs?

| Feature/Dimension | Description | Importance |

|---|---|---|

| Worktable Size | Dimensions of the worktable to accommodate specific part sizes. | Essential for fitting the components you frequently work on. |

| Spindle Speed | Maximum speed the spindle can achieve, measured in RPM. | Determines the machining speed and surface finish quality. |

| Tool Capacity | Number of tools the machine can hold. | Important for reducing downtime during setup and tool changes. |

| Axis Travel | Movement limits of the axes in X, Y, and Z directions. | Crucial for the size and complexity of parts that can be machined. |

| Control System | Type of CNC control used for operation. | Affects ease of use, programming capabilities, and integration with CAD/CAM. |

| Accuracy and Tolerance | Precision and repeatability of machining operations. | Critical for industries requiring high precision, such as aerospace. |

| Price Range | Cost of the machining center. | Important for budgeting and financial planning. |

Key Factors to Consider When Selecting a Horizontal Machining Center

When selecting a horizontal machining center, several key factors come into play. One critical aspect is the size of the workpiece. Understanding the maximum dimensions your machine can handle is essential. A larger machine may be needed for bigger projects, but it could also consume extra space. Assess your production needs carefully.

Another important consideration is the spindle speed. Faster speeds can enhance productivity, but are they necessary for your tasks? Balancing speed with the type of materials you work with is important. For precision, look into the rigidity of the structure. A stable machine contributes to accuracy and reduces vibrations during operation.

Additionally, don't overlook the control system. User-friendly interfaces can significantly streamline operations. However, advanced features might lead to longer training times. It's a trade-off. Pay attention to the available tooling options as well. Flexibility in tooling can allow for a wider range of applications, but it also means you may require more investment in accessories. Carefully evaluate how these factors align with your long-term goals and immediate requirements.

Assessing Your Budget and Cost of Ownership

When selecting a horizontal machining center, budget is crucial. Consider not just the purchase price. Maintenance costs can add up quickly. Spare parts for some models may be pricier. Always factor in potential repairs. A seemingly affordable option might lead to higher long-term expenses.

Evaluate operational costs as well. Think about energy efficiency. Some machines consume more power than others. This can impact your budget significantly. Also, consider setup and training expenses. Will you need extra help educating your staff? Don't overlook these factors—plan ahead.

However, it's easy to underestimate the total cost of ownership. A lower initial price may attract you. Yet, hidden costs could surface later. Take your time analyzing options. Make charts and calculations if needed. Costs should guide you but be wary of quick decisions that could create financial strain. Reflect on what truly serves your business needs.

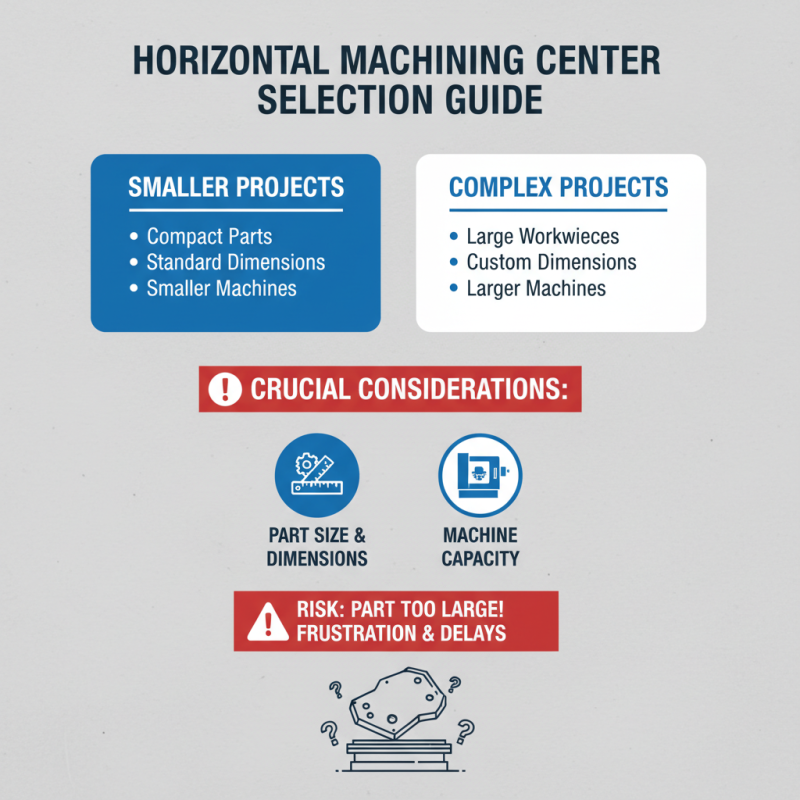

Evaluating Size and Capacity Requirements for Your Projects

When choosing a horizontal machining center, size and capacity are crucial. Consider the dimensions of the parts you will work with. A larger workpiece requires a bigger machine. If you venture into complex projects, failing to assess these needs can lead to issues. Picture a part too large for your machine—a frustrating setback for any project.

Capacity also plays a vital role. Assess how many parts you need to produce simultaneously. If you underestimate this, production can slow down significantly. For instance, if your shop often deals with batch production, a machine with minimal tool capacity may hinder efficiency. In this case, you might often run out of tools, disrupting workflow.

Reflect on your future projects, too. What materials will you use? Will you need specialized attachments? The right choice can save money and time down the road. Be wary of falling for machines loaded with features you don’t need. Each feature should enhance, not complicate, your work. This requires you to evaluate your actual requirements honestly.

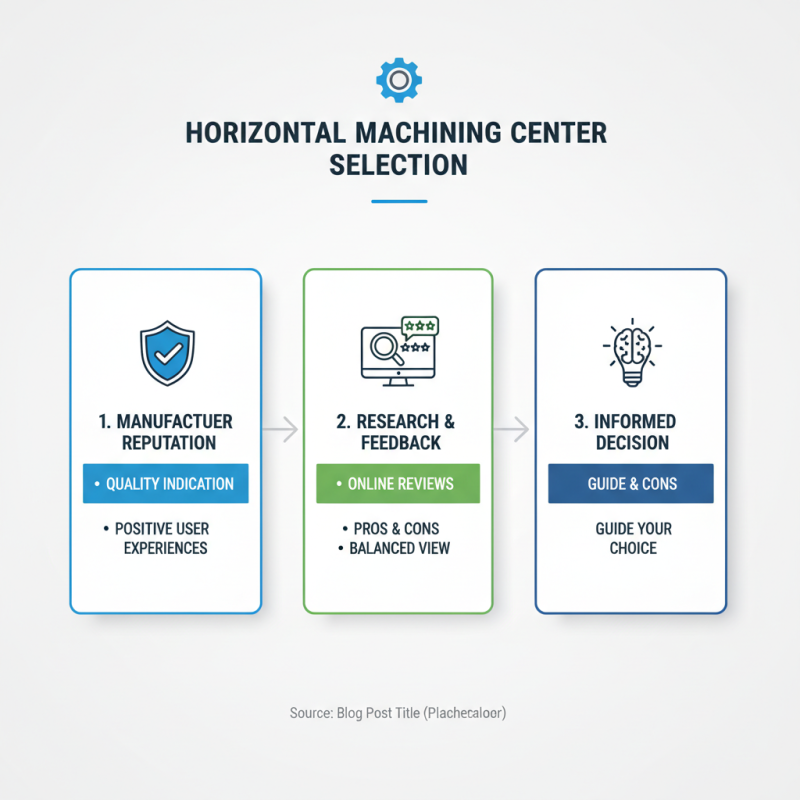

Researching Manufacturer Reputation and Support Services

When selecting a horizontal machining center, considering the manufacturer’s reputation is crucial. A strong reputation often reflects quality. It indicates that other users have had positive experiences. Reviews and feedback can be found online. Look for both positive and negative comments for a balanced view. This insight can guide your decision-making process.

Support services are equally important. A manufacturer that offers robust support can save you time and money. You need to know if they provide training, maintenance, or spare parts. Timely support can be a game-changer when production halts. It’s wise to contact the manufacturer directly to gauge their responsiveness.

Don’t forget to consider the warranty offered. A limited warranty might indicate a lack of confidence in product durability. Reflect on your own business needs and potential challenges too. High-quality machinery is essential, but support is vital. It ensures smooth operations and reduces downtime.

Related Posts

-

Top 10 Benefits of Using Horizontal Machining Centers for Efficient Manufacturing

-

The Consistent Quality of Trusted Chinese Manufacturers in Best Milling Machines

-

10 Essential Insights About CNC Metal Milling Machines You Should Know

-

Exploring the Top Alternatives to Best CNC Turning for Precision Manufacturing

-

How to Choose the Best CNC Metal Milling Machine for Your Projects in 2025

-

What is CNC Machine Tools and How They Transform Modern Manufacturing