Blog

How to Choose the Best CNC Metal Milling Machine for Your Projects in 2025

As the demand for precision engineering continues to grow in various industries, selecting the right CNC metal milling machine has become a critical decision for professionals and enthusiasts alike. In 2025, advancements in technology and materials will further influence the capabilities and functionalities of these machines. According to Dr. Emily Carter, a leading expert in CNC machinery technology, "The future of CNC metal milling machines lies in their ability to integrate artificial intelligence and adaptive learning, making it essential for buyers to consider not only the machine’s specifications but also its adaptability to future innovations."

When choosing a CNC metal milling machine, factors such as the machine's precision, size, and the types of materials it can handle must be evaluated thoroughly. Understanding the specific requirements of your projects will allow you to make an informed decision that maximizes efficiency and quality while minimizing operational costs. As technology progresses, understanding the potential features and advancements in CNC metal milling machines will be vital for anyone looking to stay ahead in the competitive landscape of manufacturing and design.

Understanding CNC Metal Milling Machines and Their Applications

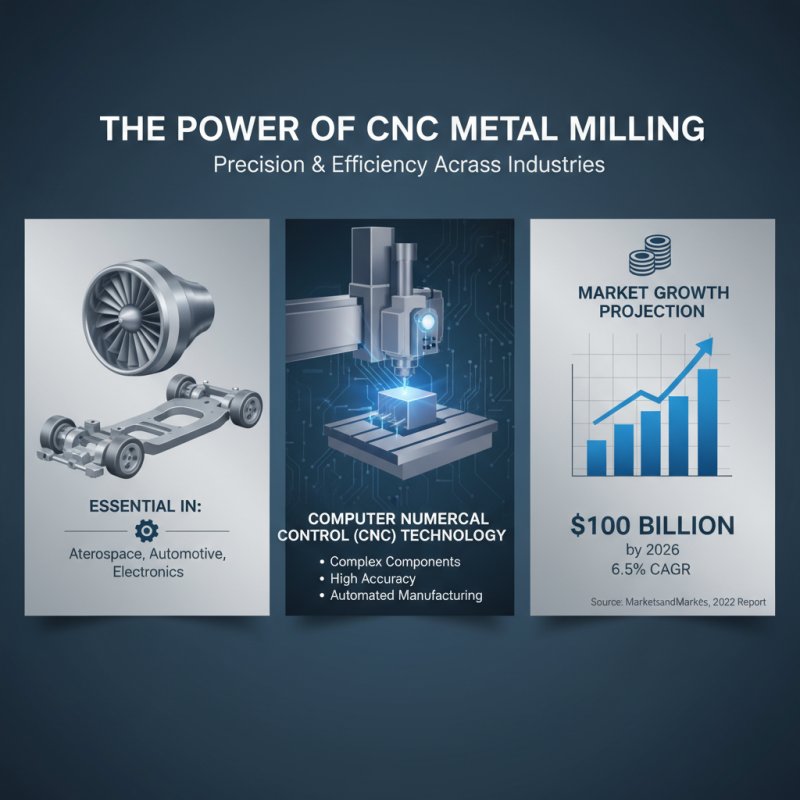

CNC metal milling machines have become essential in various industries, including aerospace, automotive, and electronics, due to their precision and efficiency. These machines utilize computer numerical control (CNC) technology, enabling operators to produce complex components with high accuracy. According to a 2022 research report by MarketsandMarkets, the global CNC milling machine market is projected to reach $100 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.5%. This growth is driven by the increasing demand for automated and precise manufacturing processes in modern industrial applications.

In understanding the applications of CNC metal milling machines, it is noteworthy that they are utilized for machining parts such as gears, brackets, and housings across multiple sectors. For instance, the aerospace industry relies on CNC milling for creating lightweight yet durable components that meet stringent safety standards. The automotive sector employs these machines for producing intricate parts that require careful engineering. Furthermore, a study from Grand View Research highlighted that the rising trend for customized machinery solutions is fostering the adoption of CNC milling technologies, enhancing production capabilities and reducing lead times for manufacturers.

Choosing the right CNC metal milling machine for specific projects in 2025 will hinge on understanding these diverse applications and their implications for production. Evaluating project requirements, such as material type and part complexity, will be crucial in selecting a machine that aligns with operational goals and maximizes efficiency. As technology continues to advance, CNC milling machines will undoubtedly play an integral role in the evolution of manufacturing practices.

Key Features to Consider When Choosing a CNC Metal Milling Machine

When selecting the best CNC metal milling machine for your projects in 2025, there are several key features to consider that can influence your operational efficiency and product quality. One of the most critical aspects is the machine's spindle speed and power. According to a report by MarketsandMarkets, advancements in spindle technology are expected to drive the market growth of CNC milling machines, as these features enhance the material removal rate and enable precision machining of various metals. A higher spindle speed allows for better surface finish and reduced machining time, making it imperative to evaluate the specifications relative to your specific projects.

Additionally, the size and rigidity of the CNC milling machine are vital factors to consider, particularly if you are working with larger workpieces or harder materials. Research from Technavio indicates that machines with enhanced rigidity reduce vibrations, leading to improved accuracy and longer tool life. It's essential to assess the frame structure and weight of potential machines, as a robust build will contribute to the overall performance, especially during large-scale manufacturing runs. Lastly, consider the machine’s control system and compatibility with CAD/CAM software, as an intuitive interface can significantly reduce setup time and improve operational efficiency, ensuring that your investment aligns with future technological advancements in CNC machining.

How to Choose the Best CNC Metal Milling Machine for Your Projects in 2025 - Key Features to Consider

| Feature | Description | Importance |

|---|---|---|

| spindle speed | A higher spindle speed allows for faster milling and better finishes. | High |

| Cutting area size | The size of the material you can machine effectively. | Medium |

| Control software | User-friendly software can significantly enhance productivity. | High |

| Precision | The machine's ability to produce accurate results. | Critical |

| Material compatibility | Ability to work with various types of metals. | Medium |

| Price | Determine your budget for a CNC machine that meets your needs. | High |

| Support and maintenance | Access to reliable technical support and maintenance services. | Important |

Evaluating Your Project Requirements and Material Compatibility

When choosing a CNC metal milling machine, evaluating your project requirements and material compatibility is crucial. Understanding the specific demands of your projects can influence the type of machine you need. For instance, if you're working with high-strength alloys or intricate geometries, you may require a machine with high torque capabilities and precision controls. Data from industry reports indicate that the global CNC machine market is projected to reach $100 billion by 2025, highlighting the growing demand for advanced milling technologies tailored to diverse materials and applications.

Material compatibility is equally important. Selecting the right milling machine requires considering the types of metals you will be working with, such as aluminum, steel, or titanium. Each material has distinct machining parameters including feed rates, spindle speeds, and tooling requirements. According to a recent study by the International Journal of Advanced Manufacturing Technology, operators can enhance efficiency by up to 30% when the machining process is optimized for specific materials. Therefore, reviewing the specifications of potential CNC milling machines against the materials in your project can lead to better outcomes, reducing waste and improving precision.

Budgeting for Your CNC Metal Milling Machine Purchase

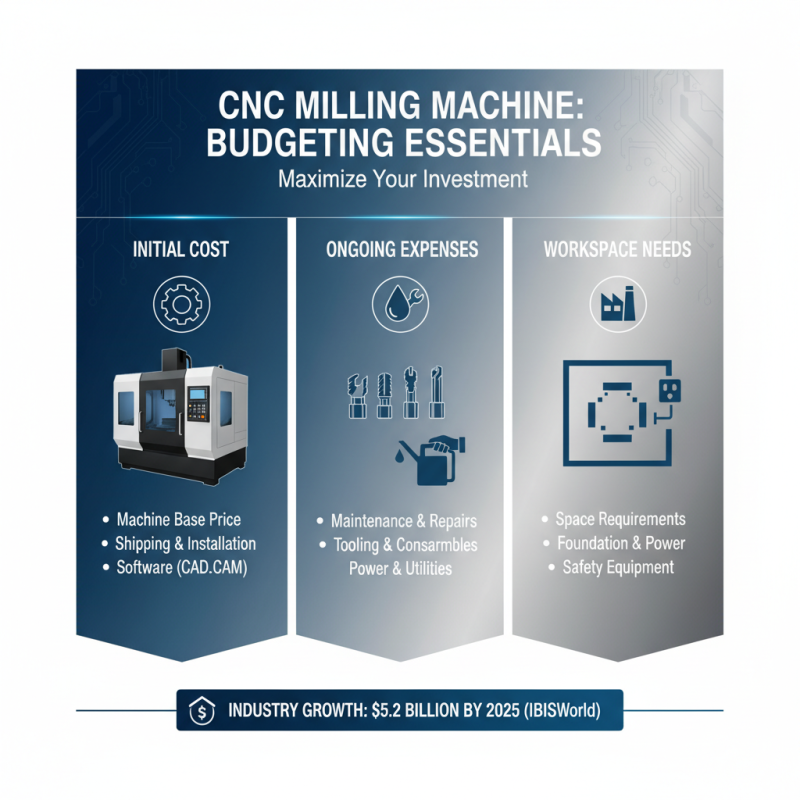

When budgeting for a CNC metal milling machine purchase, it's essential to consider not just the initial cost but also ongoing expenses such as maintenance, tooling, and workspace needs. According to a recent report by IBISWorld, the CNC machine manufacturing industry is expected to reach a market size of $5.2 billion by 2025. This growth highlights the increasing demand for precision equipment across various sectors, making a well-planned budget crucial for maximizing your investment.

Tips for budgeting effectively include setting a clear upfront cost limit, which should incorporate the purchase price of the milling machine and additional costs like software and training. It's also beneficial to allocate funds for future upgrades, as technology continually evolves. For instance, research indicates that new software tools can enhance machining efficiency by up to 30%, which emphasizes the importance of considering upgrades during your budgeting process.

Additionally, factor in operational costs such as electricity, tooling, and maintenance services. A well-maintained CNC milling machine can have a lifespan of over 10 years, but neglecting maintenance could lead to higher repair costs and downtime, which can impact your overall productivity. Keeping a reserve for unexpected expenses can also be a wise move, as the unpredictable nature of the manufacturing industry means costs can vary significantly.

Future Trends in CNC Technology and Their Impact on Machine Selection

As we move into 2025, the landscape of CNC technology is evolving rapidly, driven by advancements in automation, artificial intelligence, and material science. Industry reports indicate that the global CNC machine market is projected to reach approximately $100 billion by 2025, growing at a compound annual growth rate (CAGR) of about 7.5%. This surge reflects a growing demand for precision manufacturing across various sectors, including aerospace, automotive, and medical devices. The rise of Internet of Things (IoT) integration in CNC machines facilitates real-time monitoring and predictive maintenance, thereby enhancing operational efficiency and reducing downtime.

Moreover, the incorporation of AI and machine learning algorithms is becoming a vital factor in the machine selection process. Machines equipped with these technologies can analyze extensive datasets to optimize machining parameters and improve product quality. According to a report by MarketsandMarkets, smart manufacturing technologies, which encompass these advancements, are expected to account for over 30% of the overall manufacturing technologies by 2025. As such, when choosing a CNC milling machine, it's crucial to consider not only the immediate technical specifications, such as spindle speed and feed rate, but also the machine's compatibility with future tech trends, such as automated data analytics and deeper machine learning capabilities. This forward-thinking approach will ensure that your investments remain relevant and capable of adapting to the ever-evolving demands of the manufacturing industry.

Related Posts

-

10 Essential Insights About CNC Metal Milling Machines You Should Know

-

7 Compelling Advantages of Using CNC Metal Milling Machines in Modern Manufacturing

-

What is CNC Machine Tools and How They Transform Modern Manufacturing

-

Exploring the Unique Features and Applications of Best CNC Turning Products in Modern Manufacturing

-

Maximizing ROI with Top 5 Axis CNC Mills and the Future of After Sales Support and Maintenance Costs

-

Understanding the Importance of Best CNC Manufacturing in Global Supply Chains