Blog

What is a chemical raw materials manufacturer and its role?

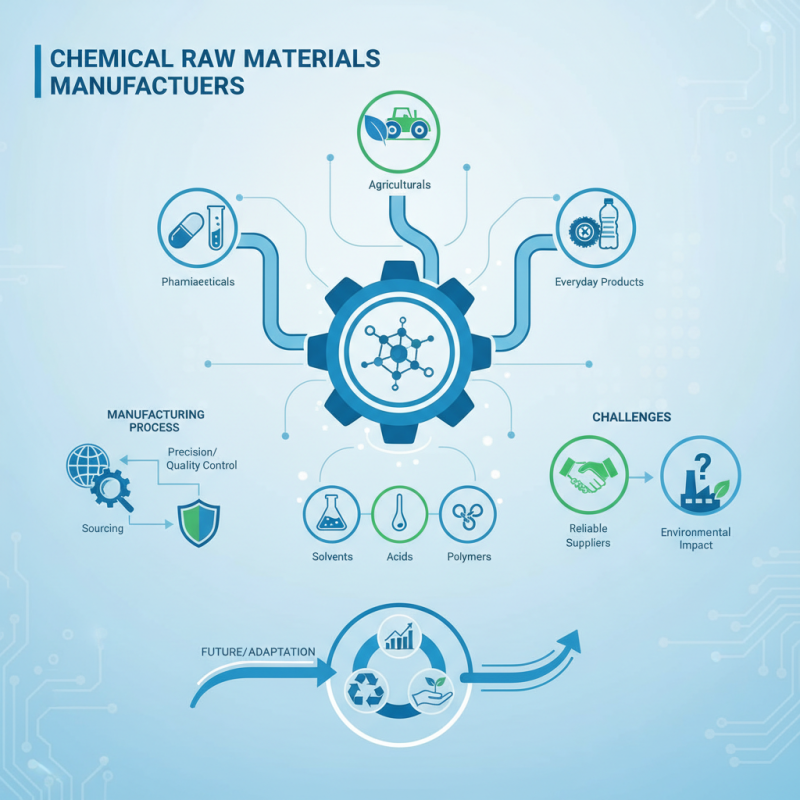

In the complex world of manufacturing, a chemical raw materials manufacturer plays a crucial role. Experts like Dr. Emily Chen, a leading figure in the industry, emphasize, "The foundation of any chemical product starts with quality raw materials." These manufacturers provide essential ingredients used in numerous industries, from pharmaceuticals to agriculture.

Chemical raw materials are essential for producing everyday products. They include solvents, acids, and polymers. The manufacturing process is intricate and requires precision. Companies must ensure the safety and quality of their materials. However, challenges often arise, such as sourcing reliable suppliers or managing environmental impacts.

While the industry continuously evolves, it’s clear that chemical raw materials manufacturers must adapt. The demand for sustainable practices is growing. These manufacturers need to reflect on their methods. They must find ways to minimize waste and enhance efficiency. Ultimately, their decisions affect the entire supply chain.

What are Chemical Raw Materials?

Chemical raw materials are fundamental substances used in the production of various products. They serve as the building blocks for countless industries. These materials include chemicals, minerals, and natural substances used in manufacturing processes.

In the production sector, the role of chemical raw materials is crucial. They are processed and transformed into more complex products. For example, petrochemicals are used to create plastics and synthetic fibers. Likewise, agrochemicals are vital for agriculture, enhancing crop yields and protecting against pests.

However, sourcing these materials comes with challenges. Quality can vary significantly between suppliers. Manufacturers must ensure consistency and reliability. Additionally, environmental impacts are a major concern. Extracting and processing raw materials often affect ecosystems. These factors require careful consideration. Balancing quality, cost, and sustainability is not an easy task.

Types of Chemical Raw Materials Used in Manufacturing

Chemical raw materials play a crucial role in various manufacturing processes. These materials serve as essential building blocks for numerous products, from plastics to pharmaceuticals. According to a recent report by Grand View Research, the global chemical manufacturing market size was valued at over $4 trillion in 2022. This highlights the significance of chemical raw materials in the economy.

The types of chemical raw materials are diverse. They include organic and inorganic chemicals, polymers, and industrial gases. Organic chemicals, such as solvents and dyes, are widely used in textiles and coatings. In contrast, inorganic chemicals like acids and alkalis find applications in agriculture and metal production. Notably, polymers, which include plastics and elastomers, make up about 20% of the global chemical market. Yet, the reliance on fossil fuels for these materials raises environmental concerns.

Moreover, emerging trends show that sustainable alternatives are gaining traction. Bio-based chemicals are becoming more popular due to their lower environmental impact. However, the transition to these alternatives often faces challenges, including higher production costs and technological barriers. This dynamic landscape prompts the industry to reflect on its sustainability goals. Finding a balance between economic growth and environmental responsibility is ongoing.

Types of Chemical Raw Materials Used in Manufacturing

| Material Type | Common Uses | Properties | Examples of Applications |

|---|---|---|---|

| Solvents | Paints, coatings | Volatile, hydrophobic | Paint manufacturing, cleaning solutions |

| Polymers | Plastics, textiles | Durable, flexible | Packaging, automotive parts |

| Acids | Food preservation, fertilizers | Corrosive, reactive | Chemical synthesis, pH adjustment |

| Bases | Detergents, soaps | Alkaline, corrosive | Cleaning agents, pharmaceuticals |

| Oxidizers | Bleaching agents, explosives | Reactive, powerful | Paper production, pyrotechnics |

The Role of Chemical Raw Materials Manufacturers in Industry

Chemical raw materials manufacturers play a vital role in various industries. These manufacturers produce basic substances used to create finished products. According to a report by Grand View Research, the global chemical raw materials market size was valued at over $4 trillion in 2022, reflecting significant growth and demand.

Manufacturers supply essential materials for sectors like pharmaceuticals, agriculture, and construction. For example, chemical raw materials like acids, solvents, and polymers are crucial for product formulation. The agricultural sector relies heavily on fertilizers and pesticides derived from chemical raw materials. A report by IBISWorld indicates that this segment alone has grown at an average annual rate of 3.1% over the last five years.

Yet, the industry faces challenges. Environmental regulations and sustainability issues are becoming more stringent. Manufacturers must innovate to reduce waste and energy use. According to a study by McKinsey, nearly 75% of chemical companies are questioning their current practices. Many are seeking sustainable alternatives, pushing the industry towards greener solutions. This shifting landscape requires raw materials manufacturers to adapt quickly, or risk falling behind.

Processes Involved in Chemical Raw Material Production

The production of chemical raw materials involves several critical processes. These processes can be complex and vary significantly based on the type of chemicals being manufactured. For example, the initial step, synthesis, may involve combining different chemical compounds under controlled conditions. This requires precision in measurement and an understanding of chemical reactions. According to reports from industry analysts, about 60% of production failures are linked to inadequate synthesis processes.

After synthesis, purification is essential. This stage removes impurities and by-products, ensuring the quality of the final chemical. Techniques such as distillation and filtration are commonly employed. Recent statistics show that nearly 30% of production costs arise from this refinement process. Moreover, the efficiency of purification can directly affect market competitiveness. Many manufacturers struggle with efficiency, resulting in higher operational costs.

Lastly, formulation is required to create finished products. This process must consider the specific needs of various industries. For instance, the coatings industry has strict standards for performance and environmental impact. Notably, a study indicated that about 20% of manufacturers reported difficulties in formulating products that meet these standards. Thus, while the processes of chemical raw material production are well-defined, challenges remain. These issues require ongoing attention and innovation within the industry.

Production Volume of Chemical Raw Materials by Type in 2023

This bar chart illustrates the production volume of different types of chemical raw materials in million tons for the year 2023. The data highlights the prominence of petrochemicals in the chemical industry, followed by inorganic and plastic materials.

Importance of Quality Control in Chemical Manufacturing

Quality control is essential in chemical manufacturing. An industry report from the American Chemistry Council indicates that quality issues can lead to significant losses. These losses may range from financial penalties to product recalls, which can damage a manufacturer's reputation.

One critical aspect is raw material inspection. Manufacturers must ensure that every chemical component meets stringent safety standards. A survey showed that up to 30% of chemical production issues stem from raw material inconsistencies. This statistic highlights the need for thorough testing before production begins. Visual inspections and documentation are necessary in this process.

Additionally, routine audits are essential in maintaining quality. However, many companies fall short in this area. Not all manufacturers regularly evaluate their quality control systems. A lapse can result in unsafe products reaching consumers. Manufacturers must commit to continuous improvement. They should reflect on their practices to identify weaknesses and areas for growth.