Blog

Essential Checklist for Global Buyers to Choose the Right Milling Machine for Their Manufacturing Needs

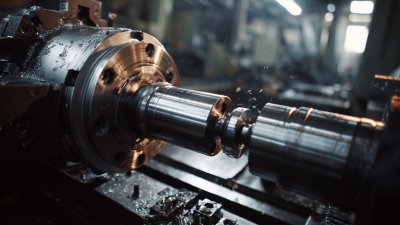

In today’s competitive manufacturing landscape, selecting the right milling machine is crucial for global buyers seeking to optimize their production processes and enhance efficiency. Milling machines are versatile tools that can significantly impact the quality and precision of manufactured products. With a multitude of options available, from CNC milling machines to manual models, making an informed decision requires careful consideration of various factors.

This essential checklist will guide global buyers through the critical criteria to evaluate when choosing a milling machine, ensuring that their investment aligns with their specific manufacturing needs. By leveraging this guide, buyers can navigate the complexities of the milling machine market and ultimately enhance their operational capabilities.

Exploring Alternative Milling Machine Types for Diverse Manufacturing Needs

When it comes to milling machines, buyers need to consider the various types that cater to different manufacturing demands. Traditional vertical and horizontal milling machines are often the first options that come to mind. Vertical mills are ideal for straightforward tasks, where precision and a variety of operations are required. On the other hand, horizontal milling machines excel in heavier and more robust applications, allowing for deeper cuts and a more extensive range of tooling options. Understanding the distinctions in functionality can greatly influence the choice based on the specific manufacturing needs.

Additionally, for buyers exploring more niche applications, CNC milling machines have emerged as a powerful alternative. These computer-controlled machines offer unmatched accuracy and repeatability, making them suitable for complex designs and high-volume production. Specialized machines like universal milling machines and bed mills also provide versatility for unique requirements, enabling manufacturers to optimize their processes. As global buyers assess their options, considering the technology and versatility of these alternative milling machine types will empower them to make informed decisions that align with their production goals.

Key Considerations When Evaluating Milling Machine Alternatives

When evaluating milling machine alternatives, buyers should first consider the specific manufacturing needs and production volume requirements. Understanding the material types, dimensions, and desired tolerances is crucial. Different milling machines offer varied capabilities like speed, precision, and versatility, which directly impact production efficiency. For instance, a high-speed machining center may be ideal for large-scale operations, while a compact CNC milling machine could be more suitable for smaller shops specializing in complex parts.

Another key consideration is the maintenance and support associated with the milling machines. Buyers should investigate the availability of spare parts, the ease of servicing the machine, and the manufacturer’s warranty conditions. Additionally, the technical training provided by the manufacturer or distributor can significantly influence the end-user’s ability to maximize the machine's features. Investing in a machine with robust support and training options can reduce downtime and enhance productivity, making it a critical factor in the decision-making process for global buyers seeking the right milling machine.

Comparing Traditional vs. Advanced Milling Technologies

In the rapidly evolving landscape of manufacturing, the choice between traditional and advanced milling technologies is crucial for global buyers seeking to optimize their production processes. Traditional milling machines have long been the backbone of manufacturing, valued for their reliability and precision. However, recent technological advancements, particularly in automation and computer-aided design, offer compelling advantages, making advanced milling technologies increasingly attractive. According to a recent industry report, the global CNC milling machine market is projected to reach USD 100 billion by 2025, driven by the increasing demand for efficiency and flexibility in manufacturing processes.

One key comparison lies in the integration of smart technologies. Advanced milling machines often incorporate features such as IoT connectivity and real-time data analytics, enabling manufacturers to enhance production capabilities while minimizing downtime. For instance, a study indicated that companies utilizing advanced milling technologies could reduce operational costs by up to 25% and improve lead times by 30%. With the rise of Industry 4.0, embracing these advanced technologies is not just a trend but a necessary shift to remain competitive in the global market. This evolution signifies a pivotal change in how manufacturers approach production, reflecting a broader movement toward sustainability and smart manufacturing principles.

Understanding the Benefits of CNC versus Manual Milling Options

When it comes to selecting a milling machine, manufacturers often find themselves weighing the advantages of CNC (Computer Numerical Control) milling against traditional manual options. CNC milling machines offer unparalleled precision and consistency, making them ideal for high-volume production runs. They are programmed to carry out complex tasks with minimal human intervention, thereby reducing errors and increasing productivity. Furthermore, the ability to store and replicate settings ensures that once a design is finalized, it can be manufactured repeatedly with exacting standards.

On the other hand, manual milling machines provide flexibility and a hands-on approach that many traditionalists appreciate. These machines are often more affordable and easier to maintain, making them a suitable choice for small-scale operations or educational settings. Additionally, skilled operators can quickly make adjustments on the fly, accommodating unique or intricate designs that may not yet warrant the investment in CNC technology. For global buyers, understanding these differences is crucial in determining which milling machine aligns best with their operational needs and manufacturing goals.

Factors Influencing the Choice of Milling Machine Alternatives in Global Markets

When selecting a milling machine for manufacturing needs in global markets, several critical factors come into play. A comprehensive report by Grand View Research indicates that the global milling machine market is projected to reach $82.3 billion by 2025, growing at a CAGR of 5.3%. This growth trajectory is primarily driven by the increasing demand from the aerospace, automotive, and defense industries, pushing buyers to consider machine efficiency, precision, and adaptability when making their choice.

Another essential factor is the technological advancements in milling machines. A study published in the Journal of Manufacturing Science and Engineering highlights that CNC (Computer Numerical Control) machines have improved machining accuracy by up to 50% compared to traditional methods. As manufacturers increasingly lean toward high-precision operations, global buyers must prioritize machine capabilities such as automation, cutting tool versatility, and the presence of advanced software for enhanced operational control. Additionally, geographical factors should not be overlooked, as local market dynamics and distribution logistics can significantly influence the overall cost and availability of these machines.

Essential Checklist for Global Buyers to Choose the Right Milling Machine

| Milling Machine Type | Key Features | Typical Applications | Cost Range (USD) | Maintenance Level |

|---|---|---|---|---|

| Vertical Milling Machine | High precision, adjustable speed | Prototype fabrication, small batch production | $5,000 - $20,000 | Low |

| Horizontal Milling Machine | Heavy-duty, high stability | Large scale production, metalworking | $15,000 - $50,000 | Moderate |

| CNC Milling Machine | Computer controlled, multi-axis capabilities | Complex part manufacturing, automotive | $30,000 - $100,000+ | High |

| Bed Milling Machine | Rigid structure, large worktable | Heavy components machining, aerospace | $25,000 - $70,000 | Moderate |

| Universal Milling Machine | Versatile, adjustable table | General machining, tool and die | $10,000 - $40,000 | Low |

Related Posts

-

The Consistent Quality of Trusted Chinese Manufacturers in Best Milling Machines

-

Innovative Solutions for Global Sourcing of the Best Milling Machines

-

Master Your Craft with the Ultimate Guide to the Best Small CNC Machine for Your Business

-

7 Game-Changing Reasons to Choose a Home CNC Machine for Your DIY Projects

-

How to Choose the Best Small CNC Machine in 2025 with Emerging Technology Trends

-

How to Identify Top Suppliers for the Best CNC Equipment: A Comprehensive Guide