Blog

5 Amazing Benefits of Using Horizontal Milling Machines in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, efficiency and precision are paramount. One of the tools that has significantly contributed to these aspects is the horizontal milling machine. This remarkable equipment offers a plethora of advantages that set it apart from conventional milling machines, making it an indispensable asset in various industries. From enhanced productivity and superior surface finishes to greater versatility in cutting complex shapes, a horizontal milling machine can transform the way manufacturing processes are executed. In this blog, we will explore five amazing benefits of utilizing horizontal milling machines, demonstrating how they can elevate operations, streamline workflows, and meet the increasing demands of contemporary production. Whether you're a seasoned machinist or a newcomer to the industry, understanding the advantages of this technology could be the key to unlocking unprecedented levels of efficiency and craftsmanship.

Advantages of Precision Cutting with Horizontal Milling Machines

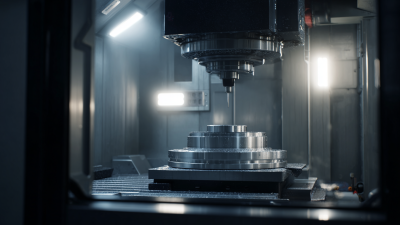

In modern manufacturing, precision is key, and horizontal milling machines are at the forefront of achieving unparalleled accuracy in cutting. These machines excel in producing intricate parts with tight tolerances, making them indispensable for industries requiring high precision, such as aerospace and automotive. The horizontal orientation allows for better chip removal and enhanced stability during the cutting process, which translates to cleaner cuts and extended tool life. This feature is particularly beneficial when working with tough materials, where precision cutting can significantly reduce the risk of tool breakage during machining operations.

Furthermore, horizontal milling machines offer versatility in operations. They can perform various tasks simultaneously, such as slotting, drilling, and contouring, without the need for multiple setups. This multi-functionality not only saves time but also minimizes the chances of errors that can occur during workpiece repositioning. As manufacturers continually strive for efficiency and quality, the advantages of precision cutting with horizontal milling machines stand out, proving that investment in advanced machining technology yields significant returns in productivity and product quality.

5 Amazing Benefits of Using Horizontal Milling Machines in Modern Manufacturing

Enhancing Production Efficiency Through Horizontal Milling Techniques

Horizontal milling machines are revolutionizing modern manufacturing by significantly enhancing production efficiency. With their robust design and versatile capabilities, these machines excel in handling heavy workloads and producing complex parts quickly. The horizontal orientation allows for better chip removal and coolant flow, leading to more effective machining processes compared to vertical milling machines. This efficiency is particularly beneficial in high-volume production environments where time and accuracy are paramount.

Horizontal milling machines are revolutionizing modern manufacturing by significantly enhancing production efficiency. With their robust design and versatile capabilities, these machines excel in handling heavy workloads and producing complex parts quickly. The horizontal orientation allows for better chip removal and coolant flow, leading to more effective machining processes compared to vertical milling machines. This efficiency is particularly beneficial in high-volume production environments where time and accuracy are paramount.

Tip: To maximize the benefits of horizontal milling, ensure proper tool selection. Using the right cutting tools can dramatically improve surface finish and reduce machining time. Investing in high-quality carbide inserts can enhance performance, allowing operations to run faster and with less wear.

Furthermore, horizontal milling machines can be integrated with advanced automation technologies, such as robotic arms and CNC controls. This integration leads to a seamless workflow, minimizing human error and maximizing output. When combined with real-time monitoring systems, manufacturers can optimize their processes and quickly adjust to changes in production demands.

Tip: Regular maintenance is crucial for maintaining efficiency. Implement a routine check-up schedule to ensure that all components of the milling machine are in perfect working condition. This proactive approach helps prevent unexpected downtimes, ensuring a smooth and continuous manufacturing process.

Cost Savings in Manufacturing: The Impact of Horizontal Milling

In modern manufacturing, horizontal milling machines have emerged as pivotal tools that significantly contribute to cost savings. According to a recent report by the National Association of Manufacturers (NAM), companies have the potential to reduce production costs by up to 20% when integrating advanced milling technology into their operations. This is largely attributed to the efficiency and speed that horizontal milling machines deliver, allowing for the processing of multiple surfaces in a single setup. Such multitasking capabilities not only minimize machine wear and tear but also reduce setup times, directly translating to lowered labor costs.

Moreover, the precision offered by horizontal milling machines enhances material utilization, leading to minimized waste. A study by Deloitte highlights that manufacturers employing such machinery can see a decrease in scrap rates by as much as 30%. Enhanced material efficiency not only contributes to lower raw material costs but also supports sustainability initiatives by reducing the environmental impact of manufacturing operations. This compelling combination of efficiency, precision, and waste reduction positions horizontal milling machines as a smart investment for manufacturers aiming to optimize their operations while staying competitive in a rapidly evolving market.

5 Amazing Benefits of Using Horizontal Milling Machines in Modern Manufacturing - Cost Savings in Manufacturing: The Impact of Horizontal Milling

| Benefit | Description | Cost Impact | Efficiency Gain (%) |

|---|---|---|---|

| Precision | Delivers high precision and accuracy in machining processes. | Reduces waste and rework costs by up to 20%. | 15% |

| Speed | Higher cutting speeds lead to shorter production times. | Decreases labor costs by approximately 10%. | 20% |

| Versatility | Ability to perform various milling operations with one setup. | Reduces tooling and setup costs by about 15%. | 25% |

| Durability | Built to withstand heavy usage, leading to lower maintenance costs. | Saves maintenance costs by up to 30% over time. | 18% |

| Automation | Integration with automation enhances throughput and reduces errors. | Minimizes labor costs and error-related expenses by 25%. | 30% |

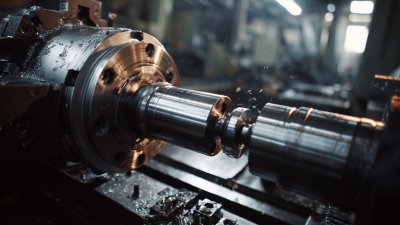

Versatility in Material Processing: Why Choose Horizontal Milling?

Horizontal milling machines have gained prominence in modern manufacturing due to their remarkable versatility in material processing. Unlike their vertical counterparts, horizontal mills offer more efficiency when handling various materials, including metals and composites. This adaptability allows manufacturers to optimize their production processes, tailoring them to meet specific project requirements without compromising on quality.

Furthermore, the advancements in milling technologies, such as ball milling, have significantly enhanced the capability to synthesize and modify nanomaterials. This technique is not limited to a single type of material; it accommodates a range of organic, inorganic, and hybrid compounds, which is essential in the growing field of nanotechnology. The use of horizontal milling machines in such applications not only streamlines production but also expands the scope of what can be achieved in material science, making them an invaluable asset in contemporary manufacturing environments.

Improving Surface Finish Quality with Horizontal Milling Machines

Horizontal milling machines have significantly transformed the landscape of modern manufacturing, particularly in enhancing surface finish quality. The ability to achieve superior surface finishes is paramount in industries where precision and aesthetics matter, such as aerospace and automotive. By utilizing advanced tooling and optimized milling strategies, manufacturers can enhance the surface integrity of components, reducing the need for extensive post-processing and lowering production costs.

Horizontal milling machines have significantly transformed the landscape of modern manufacturing, particularly in enhancing surface finish quality. The ability to achieve superior surface finishes is paramount in industries where precision and aesthetics matter, such as aerospace and automotive. By utilizing advanced tooling and optimized milling strategies, manufacturers can enhance the surface integrity of components, reducing the need for extensive post-processing and lowering production costs.

Moreover, recent advancements in hybrid manufacturing techniques that integrate 3D printing (FDM) and milling systems further bolster the capabilities of horizontal milling machines. This combination allows for the initial creation of complex geometries through additive processes, followed by precision milling to refine surfaces. Such integration not only improves the overall quality of the finished product but also accelerates the production timeline, as it streamlines the workflow from conception to completion. As the industry leans toward more sustainable and efficient practices, horizontal milling machines will undoubtedly play a crucial role in achieving these goals.

Related Posts

-

Unlocking the Future of Manufacturing with the Best Horizontal Milling Machine in 2025

-

Unlocking Efficiency The Advantages of Horizontal Milling Machines in Precision Manufacturing

-

Unmatched Quality: Discover the Best Small CNC Mill from Trusted Chinese Manufacturers

-

Ultimate Guide to Choosing the Best 5 Axis CNC Milling Machine for Your Manufacturing Needs

-

The Consistent Quality of Trusted Chinese Manufacturers in Best Milling Machines

-

Unveiling the Top 5 Technical Specifications of the Best Machining Center for Optimal Performance