Blog

What is a Ball Screw for Sale and How to Choose One?

In the realm of precision machinery, the term "ball screw for sale" often arises. Ball screws play a crucial role in converting rotary motion into linear motion, offering high efficiency. According to a recent industry report by MarketsandMarkets, the global ball screw market is projected to reach $5.6 billion by 2026, with a CAGR of 5.8%. This growth underscores the increasing demand across various sectors, including automation and robotics.

Choosing the right ball screw can be daunting. Factors such as load capacity, precision, and backlash must be considered. Many buyers overlook the importance of compatibility with existing systems. For instance, the wrong diameter can lead to inefficient movement or failure. The wrong choice not only wastes resources but can also halt production.

Additionally, while many suppliers advertise ball screws, not all meet industry standards. It's vital to verify the specifications and certifications. This diligence ensures that the selected ball screw enhances machine performance. An informed choice leads to better operational outcomes. However, mistakes still happen, reminding us of the critical nature of research and consideration in this field.

What is a Ball Screw and Its Function in Machinery?

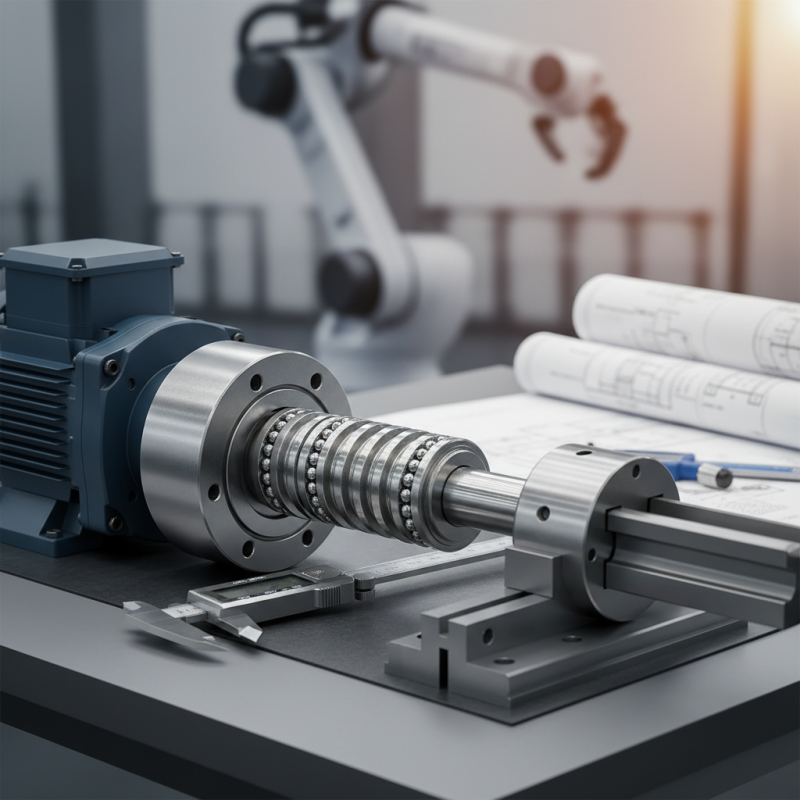

A ball screw is a vital component in machinery, converting rotational motion into linear movement. It consists of a threaded shaft and ball bearings that circulate within. This design enhances efficiency, providing lower friction and higher precision. According to industry reports, ball screws can achieve up to 90% efficiency, making them critical in automated applications.

When choosing a ball screw, consider load capacity and accuracy. The application dictates these factors. For instance, in CNC machines, precision is paramount. The diameter and pitch of the screw also matter. A smaller pitch allows for better accuracy, while a larger diameter can support heavier loads. These choices directly affect product performance.

Key Components and Design Features of a Ball Screw

Ball screws are critical components in various machinery, providing precise linear motion. They consist of a screw and a nut, which contain ball bearings that allow smooth movement. This design reduces friction, enhancing efficiency. A ball screw's key quality parameters are load capacity and durability. According to industry reports, effective use of ball screws can increase energy efficiency by up to 40%.

When choosing a ball screw, consider critical design features. The screw's diameter and lead (the distance the nut travels with one rotation) significantly impact performance. A larger diameter supports greater loads, while a finer lead allows faster movement. However, these specifications can be a balancing act. Selecting a ball screw that is too large can lead to unnecessary weight and cost.

Tips: Look for customization options. Manufacturers offer different lead and diameter sizes. Customize according to your specific application needs. Regular maintenance is key. Ball screws need lubrication to ensure longevity. Neglect can lead to premature wear. Ensure the installation aligns the screw and nut correctly. Misalignment can cause operational issues.

Types of Ball Screws Available on the Market Today

When exploring ball screws, it helps to know the types available in the market. There are typically three main varieties: rolled, ground, and hybrid ball screws.

Rolled ball screws are less expensive. They are often used in lower precision applications. Ground ball screws provide higher accuracy. They are more suitable for critical operations. Hybrid ball screws combine features from both types, offering a balance of cost and performance.

Tips: Consider your project's precision requirements. Rolled screws may suffice if your application doesn't demand high accuracy. However, invest in ground screws for tasks that need fine control.

Another essential aspect is the size and load capacity of the ball screw. Evaluate your equipment's space limitations. Choose a size that fits comfortably without needing alterations. Larger screws can handle heavier loads, but they may be more challenging to install. Finding the right size is crucial.

Tips: Measure your setup accurately before purchasing. Too often, buyers select the wrong size. This leads to issues during installation. Always check specifications and application needs more than once. A miscalculation can lead to costly mistakes.

Factors to Consider When Choosing a Ball Screw for Your Application

When selecting a ball screw for your application, several factors come into play. Load capacity is critical. According to industry reports, the maximum load a ball screw can handle directly affects its lifespan. Poorly matched loads can lead to premature wear, so understanding your application's specific requirements is essential. For instance, manufacturers often recommend testing under actual load conditions.

Next is the lead and diameter of the ball screw. The lead affects speed and accuracy. A higher lead translates to faster movement, but can compromise precision. Often, users must balance speed and accuracy based on their needs. It's worth noting that a 1 mm increase in lead can significantly impact positioning accuracy in high-precision tasks.

Additionally, consider the environment. Factors like temperature, exposure to dust, and humidity can alter performance. In hostile environments, select screws with suitable coatings or seals. The right choice can extend the lifespan of the screw. Yet, many users overlook these elements, leading to costly replacements or failures. Regular maintenance records indicate that 30% of failures stem from environmental neglect, underscoring the importance of proper considerations.

Industry Standards and Performance Metrics for Ball Screws

When selecting a ball screw, industry standards and performance metrics are essential. A ball screw is vital for precise motion control in machinery. Understanding the specifications can significantly improve your application’s efficiency. Look for load ratings, accuracy, and backlash. These factors influence how well the ball screw performs.

**Tips:** Check the load capacity against your requirements. A mismatch can lead to premature failure. Evaluate the screw's pitch and diameter. Smaller diameters may offer higher speeds but less load capacity.

In addition to these metrics, consider the environment in which the ball screw will operate. Factors like temperature and contamination can impact durability. Some ball screws perform poorly in extreme conditions. Regular maintenance can also increase lifespan. This is often overlooked but crucial for reliability.

What is a Ball Screw for Sale and How to Choose One?

| Specification | Description | Performance Metrics | Industry Standards |

|---|---|---|---|

| Diameter | Determines the load capacity and rigidity | Standard ranges: 10mm to 100mm | DIN 69051 |

| Lead | Distance the nut moves per rotation | Typical leads: 5mm, 10mm, 20mm | ISO 3408 |

| Accuracy Class | Tolerance of the screw and nut | C5, C7, C10 | DIN 69051 |

| Load Capacity | Maximum load the screw can handle | Rated dynamic and static load | ISO 3408 |

| Material | Commonly made from carbon steel or stainless steel | Material strength and fatigue resistance | ASTM A276 |