Blog

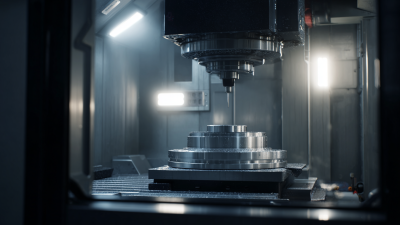

Unlocking Efficiency The Advantages of Horizontal Milling Machines in Precision Manufacturing

In the ever-evolving landscape of precision manufacturing, the adoption of advanced machinery is pivotal for unlocking efficiency and maintaining competitive advantages. Notably, the horizontal milling machine has emerged as a cornerstone of modern manufacturing processes, offering unparalleled accuracy and productivity.

According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2025, with horizontal milling machines playing a crucial role in this growth due to their ability to handle complex geometries and large workpieces efficiently.

The inherent design advantages of these machines, including robust construction and multi-directional cutting capabilities, facilitate faster production times and increased tooling flexibility.

According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2025, with horizontal milling machines playing a crucial role in this growth due to their ability to handle complex geometries and large workpieces efficiently.

The inherent design advantages of these machines, including robust construction and multi-directional cutting capabilities, facilitate faster production times and increased tooling flexibility.

As industries strive for higher operational efficiency, understanding the specific benefits and challenges associated with horizontal milling machines becomes essential for manufacturers aiming to optimize their workflows and achieve superior precision.

The Evolution of Horizontal Milling Machines in Modern Manufacturing

The evolution of horizontal milling machines has been a significant driver of transformation in modern manufacturing processes. Once considered a staple of traditional machining, these machines have adapted to meet the increasing demands for precision and efficiency. From their early mechanical designs, which relied heavily on manual operation, horizontal milling machines have progressed to incorporate advanced technologies like CNC (Computer Numerical Control). This shift not only enhances the accuracy of production but also enables manufacturers to execute complex designs with remarkable consistency.

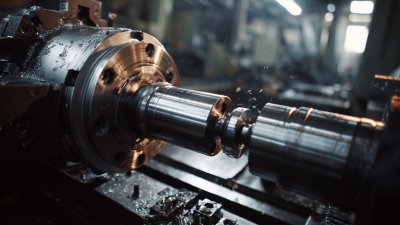

As industries continue to embrace automation, horizontal milling machines are at the forefront of enhancing productivity. Their ability to handle multiple operations—such as milling, drilling, and boring—within a single setup reduces setup times and material waste. Furthermore, advancements in tooling and materials have allowed these machines to work with a wider range of materials, including hard metals and composites. This versatility positions horizontal milling machines as indispensable tools in sectors like aerospace, automotive, and medical manufacturing, where precision is paramount. The ongoing innovations in this domain suggest a promising future, where horizontal milling machines will continue to empower manufacturers to achieve higher levels of efficiency and output.

Key Advantages of Horizontal Milling in Precision Engineering

Horizontal milling machines have gained significant attention in precision engineering due to their numerous advantages over traditional vertical machining centers. One of the key benefits of horizontal CNC machining is improved chip removal and better coolant flow, resulting in higher feed rates and enhanced machining efficiency. By transitioning to a horizontal machining center, manufacturers can achieve faster cycle times and produce complex geometries with greater accuracy, making it an ideal choice for high-precision applications.

Moreover, the evolution of technology in CNC machining, particularly the integration of artificial intelligence, is further reshaping the landscape of precision manufacturing. Modern machines are now equipped with smart features that optimize feed rates and predict cutting forces, leading to smarter machining strategies. This technological advancement, coupled with the increasing demand for precision parts, positions horizontal milling as an essential process within the manufacturing sector. The market for CNC horizontal machining centers is projected to grow substantially, driven by this focus on efficiency and productivity, highlighting the importance of staying ahead in the competitive precision engineering field.

Comparative Analysis: Horizontal vs. Vertical Milling Technologies

When it comes to precision manufacturing, the choice between horizontal and vertical milling machines can significantly influence the efficiency and quality of production. Horizontal milling machines are often favored for their ability to handle larger workpieces and provide better support during the machining process. With their configuration, these machines allow for the use of multiple cutting tools at once, leading to more efficient machining operations and shorter cycle times. As a result, manufacturers can achieve high levels of precision while optimizing their production workflows.

In contrast, vertical milling machines excel in applications that require versatility and intricate detail. Their design facilitates easy access to the workpiece, making them ideal for tasks that involve complex shapes and profiles. However, they may not be as effective as their horizontal counterparts for larger or heavier materials. The comparative analysis of these two technologies highlights that while vertical milling offers flexibility, horizontal milling machines offer unmatched efficiency in larger scale production environments. Ultimately, the selection of milling technology should be aligned with the specific needs of the manufacturing process to maximize output and precision.

Applications of Horizontal Milling Machines Across Various Industries

Horizontal milling machines play a crucial role in various industries, offering precision and efficiency for a wide range of applications. In the aerospace sector, for example, these machines are instrumental in crafting complex components, such as engine parts and structural frameworks, where exact tolerances are paramount. The horizontal design enables operators to handle larger workpieces more effectively, making it easier to produce intricate shapes that meet rigorous industry standards.

In the automotive industry, horizontal milling machines are used extensively for machining transmission cases and engine blocks. Their ability to perform multiple operations, including cutting, drilling, and finishing in a single setup, significantly reduces production time and enhances productivity. Furthermore, these machines can efficiently manage hard materials, delivering outstanding surface finishes and adjustability for custom specifications. This versatility ensures that manufacturers can keep pace with the rapid advancements in automotive technology while maintaining high-quality outputs.

Unlocking Efficiency: The Advantages of Horizontal Milling Machines in Precision Manufacturing

| Industry | Advantages of Horizontal Milling | Applications |

|---|---|---|

| Aerospace | High precision, reduced cycle times | Machining of aircraft components |

| Automotive | Enhanced speed, improved surface finish | Manufacturing of engine blocks |

| Medical Devices | Precision detailing, repeatability | Production of surgical instruments |

| Energy | Ability to handle large parts, durability | Machining components for turbines |

| Electronics | Fine tolerances, minimal waste | Manufacturing of circuit boards |

Future Trends in Horizontal Milling for Enhanced Manufacturing Efficiency

The landscape of precision manufacturing is continuously evolving, and horizontal milling machines are at the forefront of this transformation. One notable trend is the integration of advanced automation technologies, which significantly enhances operational efficiency. With the advent of smart manufacturing, these machines now come equipped with IoT capabilities, enabling real-time monitoring and predictive maintenance. This results in reduced downtime and ensures that manufacturing processes run smoothly and efficiently. As manufacturers embrace these cutting-edge technologies, horizontal milling machines are becoming increasingly adaptable, capable of handling complex geometries and diverse materials with ease.

Moreover, the emphasis on sustainability is shaping the future of horizontal milling. Manufacturers are now prioritizing energy-efficient machines that minimize waste and reduce the carbon footprint of production processes. Innovations such as energy-efficient drives and eco-friendly coolant systems not only help in conserving resources but also appeal to a market that values environmentally conscious practices. As companies seek to enhance their competitive edge, the alignment of horizontal milling technology with sustainable manufacturing principles is likely to become a defining characteristic of the industry, driving continuous improvements in efficiency and productivity.

Related Posts

-

Unlocking the Future of Manufacturing with the Best Horizontal Milling Machine in 2025

-

Exploring the Unique Features and Applications of Best CNC Turning Products in Modern Manufacturing

-

The Ultimate Checklist for Choosing the Best Mini CNC Mill for Your Business Needs

-

The Consistent Quality of Trusted Chinese Manufacturers in Best Milling Machines

-

Innovative Solutions for Global Sourcing of the Best Milling Machines

-

Ultimate Showdown of the Best Wood CNC Machines for Your Next Project