Blog

Exploring the Advancements in Milling Machine Technology for Modern Manufacturing

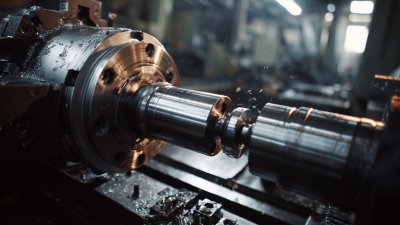

In the rapidly evolving landscape of modern manufacturing, the significance of milling machines cannot be overstated. These versatile machines have undergone remarkable advancements that enhance their efficiency, precision, and adaptability within various production environments. Exploring the latest technologies integrated into milling machines reveals a transformative journey where traditional machining dynamics are redefined through automation, intelligent control systems, and advanced materials. This article delves into the innovations shaping milling machine technology, offering valuable insights and practical tips for manufacturers seeking to leverage these advancements. By understanding these emerging trends, industry professionals can optimize their processes, reduce operational costs, and ultimately drive the competitive edge needed in today’s complex manufacturing landscape.

Understanding the Evolution of Milling Machines in Modern Manufacturing Landscapes

The evolution of milling machines has been significantly influenced by advancements in technology, which are reshaping manufacturing landscapes. The global milling machine market is projected to reach USD 116,722.7 million by 2035, driven largely by innovations in CNC (Computer Numerical Control) systems and the integration of smart automation. This growth highlights the demand for enhanced precision and productivity that modern manufacturers require, marking a shift from traditional manual operations to sophisticated automated processes.

Recent trends indicate that the incorporation of artificial intelligence and robotics is drastically transforming the manufacturing sector. These next-generation technologies are set to play a pivotal role in Africa's flour milling industry, fostering sustainability and operational efficiency. As manufacturers embrace automation, they navigate four distinct phases of evolution, from basic mechanization to advanced, fully automated systems, further underscoring the dynamic nature of milling technology in modern manufacturing contexts. This progression not only enhances productivity but also aligns with the pressing need for innovation within the industry.

Key Technological Innovations Revolutionizing Milling Processes for Enhanced Efficiency

The rapid advancements in milling machine technology are transforming modern manufacturing, enabling significant improvements in efficiency and productivity. Innovations in energy-efficient technologies, such as solar dryers and advanced milling processes, are increasingly adopted in post-harvest agriculture. These systems not only reduce energy costs but also streamline operations, allowing for faster processing times and higher product quality.

Artificial Intelligence (AI) is playing a pivotal role in this evolution, automating complex manufacturing processes and providing data-driven insights for smarter production. According to industry reports, AI integration can increase operational efficiency by as much as 30%, underscoring its value in optimizing milling operations. Additionally, the CNC machining market is projected to expand significantly, driven by the adoption of new digital manufacturing technologies. This trend indicates a shift towards more precise and reliable machining practices, which will be essential for enhancing the overall manufacturing process.

As the industry embraces these cutting-edge technologies, it's clear that the landscape of milling operations will continue to evolve, with innovations poised to drive efficiency and quality in unprecedented ways. The ability to adapt to these changes will not only redefine productivity standards but also set new benchmarks for competitive excellence in manufacturing.

Exploring the Advancements in Milling Machine Technology for Modern Manufacturing

| Feature | Description | Impact on Efficiency |

|---|---|---|

| Computer Numerical Control (CNC) | Automates the movement of the milling machine for precise manufacturing. | Increases precision, reduces waste. |

| Adaptive Control Systems | Monitors machining conditions in real-time and adjusts parameters accordingly. | Enhances productivity and tool life. |

| High-Speed Machining (HSM) | Uses high spindle speeds and feed rates to increase material removal rates. | Significantly reduces cycle times. |

| Multi-Axis Machining | Allows machining on multiple axes, enabling complex geometries. | Improves design flexibility and reduces setup time. |

| Tool Path Optimization | Utilizes software algorithms to determine the most efficient paths for tooling. | Minimizes machining time and maximizes tool efficiency. |

| Smart Sensors | Integrated sensors for monitoring conditions like temperature and vibration. | Provides data for predictive maintenance and avoids downtimes. |

Integrating Automation and Smart Technologies in Modern Milling Machine Operations

The integration of automation and smart technologies in modern milling machine operations signifies a transformative shift in the manufacturing sector. According to a 2022 report by Mordor Intelligence, the global market for advanced manufacturing technologies, including automated milling solutions, is projected to reach $105 billion by 2027, growing at a CAGR of 6.5%. This growth is largely attributed to the need for increased efficiency and precision in production processes. Smart milling machines equipped with IoT capabilities enable real-time data collection and analysis, significantly enhancing operational performance.

In practice, automated milling machines can reduce setup times and minimize human error, leading to higher product quality. A notable example is the introduction of Industry 4.0 technologies, which allows machines to communicate and self-optimize their operations. Research from the National Institute of Standards and Technology shows that leveraging these smart solutions can improve production efficiency by up to 30%. As manufacturers increasingly adopt these innovations, the competitive landscape will shift dramatically, with companies that embrace automation and smart technologies poised to lead the industry.

Exploring the Advancements in Milling Machine Technology for Modern Manufacturing

Evaluating the Impact of Advanced Materials on Milling Performance and Durability

The advancements in milling machine technology have been significantly influenced by the integration of advanced materials, leadings to improved performance and durability. Recent studies highlight the importance of selecting optimal machining strategies to enhance surface roughness, especially in specialized applications such as wood-CNC machining. This careful choice of methods can substantially elevate the quality of the end product, showcasing the pivotal role materials play in machining effectiveness.

Tips: When evaluating milling performance, consider the use of hybrid nanofluids to facilitate sustainable machining practices. This innovative approach not only enhances lubrication but also optimizes tool performance, especially when working with challenging materials like nickel superalloys. Additionally, incorporating advanced materials, such as TiAlN and polycrystalline diamond coatings, can significantly improve the machinability of various composites, leading to better outcomes in surface quality and tool longevity.

Moreover, the exploration of innovative manufacturing processes continues to gain momentum as industries strive for higher efficiency. By adopting new technologies, manufacturers can address historical declines in production capabilities, ultimately contributing to a revitalized industrial landscape. Integrating advanced materials into the manufacturing framework is not just beneficial for performance; it is essential for maintaining competitive advantage in an ever-evolving market.

Analyzing Industry Trends: The Role of CNC Mills in Driving Competitive Manufacturing Practices

The advancements in CNC milling technology have played a pivotal role in modern manufacturing, significantly enhancing operational efficiency across various industries. According to recent market analyses, the global CNC machine tools market is projected to grow by USD 21.9 billion from 2025 to 2029. This surge is primarily driven by the increasing demand for high-precision and multi-axis machining centers, as manufacturers seek to optimize their production capabilities and maintain a competitive edge. The introduction of artificial intelligence into CNC operations has revolutionized traditional practices, enabling more complex and efficient machining processes.

As industries continue to embrace digital manufacturing technologies, the CNC slitting lathes market is also expected to witness substantial growth, with a forecasted reach of USD 2.8 billion by 2035, growing at a CAGR of 5.3%. This reflects a broader trend within the sector where manufacturers are harnessing advanced CNC technologies to streamline operations, reduce waste, and enhance product quality. The emphasis on precision and efficiency is reshaping manufacturing practices, making CNC mills an indispensable asset for businesses aiming to thrive in a competitive marketplace.

Related Posts

-

Innovative Solutions for Global Sourcing of the Best Milling Machines

-

Essential Checklist for Global Buyers to Choose the Right Milling Machine for Their Manufacturing Needs

-

The Consistent Quality of Trusted Chinese Manufacturers in Best Milling Machines

-

Master Your Craft with the Ultimate Guide to the Best Small CNC Machine for Your Business

-

Ultimate Guide to Choosing the Best 5 Axis CNC Milling Machine for Your Manufacturing Needs

-

7 Game-Changing Reasons to Choose a Home CNC Machine for Your DIY Projects